Micro Star 1000

26

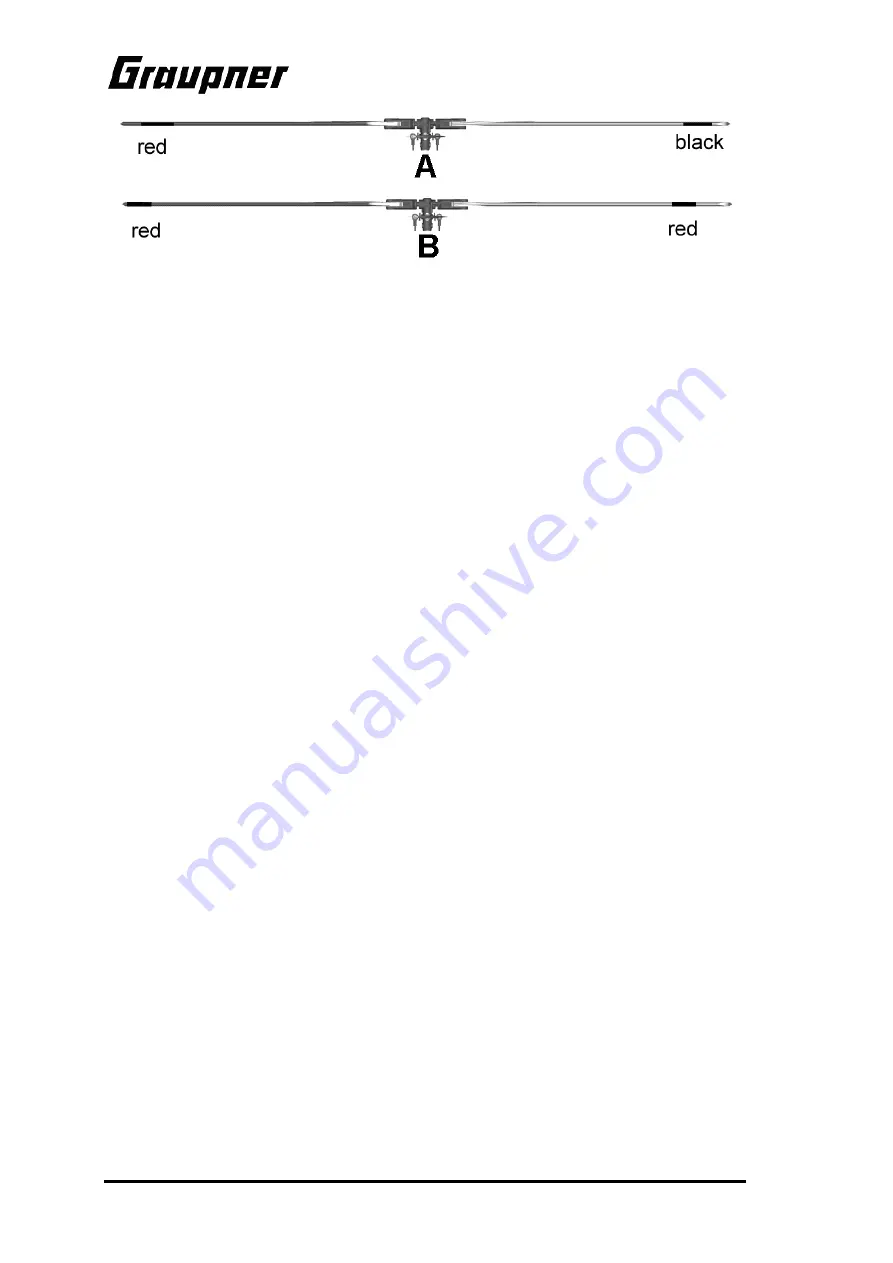

There are two alternative methods: figure “A” shows different colours on the blade tips; fig. “B”

shows the use of the same colour, but applied at different distances from the blade tip.

Procedure for adjusting blade tracking

1. Set the helicopter almost to the lift-off point, then sight directly along the rotor plane.

2. If you can see that the rotor blades are running in the same plane, no adjustment is re-

quired; however, if one blade runs higher than the other, the settings must be corrected.

3. Locate the pushrods between the swashplate and the mixer levers; the adjustment is made

at the ball-links on both ends of these pushrods: unscrew the links to lower the blade, screw

them in to raise it.

5. Maintenance

Helicopters, whether large or small, place considerable demands on maintenance. Whenever

you notice vibration in your model, take immediate steps to reduce or eliminate it. Rotating parts,

important screwed joints, control linkages and linkage junctions should be checked before every

flight. If repairs become necessary, be sure to use original replacement parts exclusively. Never

attempt to repair damaged rotor blades; always replace them with new ones.

6. General safety measures

•

Take out adequate third-party insurance cover.

•

Wherever possible join the local model flying club.

At the flying site:

•

Never fly your model above spectators.

•

Do not fly models close to buildings or vehicles.

•

Avoid flying over agricultural workers in neighbouring fields.

•

Do not fly your model in the vicinity of railway lines, major roads or overhead cables

Pre-flight checks, flying safety:

•

Before you switch on the transmitter, check carefully that no other model flyer is using the

same frequency.

•

Carry out a range check with your RC system.

•

Check that the transmitter and flight batteries are fully charged.

•

Do not let the model fly out of safe visual range.

Post-flight checks

•

Clean the model and check that all screws etc. are still tight.

•

Examine the helicopter carefully for wear and damage, and replace worn parts in good time.

•

Ensure that the electronic components such as battery, receiver, gyro etc. are still securely

fixed.

•

Check the receiver aerial. Conductor fractures inside the insulation are often not directly visi-

ble from the outside.

•

If the main rotor should touch the ground when spinning, be sure to replace the blades. Inter-

nal blade damage may not be visible from the outside.

•

Never carry the model by the tail boom: too firm a grip will easily deform the tail rotor pushrod

Содержание Micro Star 1000

Страница 30: ...Micro Star 1000 2 Replacement parts...

Страница 32: ...Micro Star 1000 4...

Страница 34: ...Micro Star 1000 6...