OM−02812

VG SERIES

PAGE B − 2

INSTALLATION

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be-

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc-

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after dry-

ing, check for loose hardware at mating sur-

faces.

c. Carefully read all warnings and cautions con-

tained in this manual or affixed to the pump,

and perform all duties indicated. Note the di-

rection of rotation indicated on the pump.

Check that the pump shaft rotates counter-

clockwise when facing the pump suction.

Only operate this pump in the direction in-

dicated by the arrow on the pump body

and on the accompanying decal. Refer to

ROTATION

in

OPERATION

, Section C.

d. Check all lubricant levels and lubricate as

necessary. Refer to

LUBRICATION

in the

MAINTENANCE AND REPAIR

section of this

manual and perform duties as instructed.

e. If the pump and

power source have been

stored for more than 12 months, some of the

components or lubricants may have ex-

ceeded their maximum shelf life. These

must

be inspected or replaced

to ensure maxi-

mum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to deter-

mine the repair or updating policy.

Do not

put the

pump into service until appropriate action has

been taken.

POSITIONING PUMP

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer-installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

The pump assembly can be seriously

damaged if the cables or chains used to lift

and move the unit are improperly wrapped

around the pump.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount-

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra-

tion.

SUCTION AND DISCHARGE PIPING

The size of the system piping is

not

always deter-

mined by the nominal suction and discharge port

diameter. Factors such as suction lift, discharge

elevation, and friction losses for the complete sys-

tem must be considered to be sure your applica-

tion allows the pump to operate within the safe op-

erating range shown on page E-1. In any case, the

suction line should never be smaller than the pump

inlet.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid-wall, rein-

Содержание VG3B3-B

Страница 14: ...GENERAL INFORMATION...

Страница 17: ...EQUIPMENT SAFETY DOCUMENTS and PRECAUTIONS...

Страница 30: ...U L MOTOR REQUIREMENTS...

Страница 31: ......

Страница 35: ...PROTECTIVE COATINGS...

Страница 37: ...PAINT TECHNICAL DATA SHEETS...

Страница 43: ...PASSIVATION DOCUMENTS...

Страница 47: ...STORAGE PROCEDURES...

Страница 51: ...INSTRUMENTATION...

Страница 56: ...VALVES...

Страница 58: ...PUMPS...

Страница 61: ...MATERIAL SAFETY DATA SHEETS...

Страница 65: ......

Страница 66: ...PAINT COATING MSDS...

Страница 73: ...ADHESIVE ANCHORS MSDS...

Страница 74: ...SIMPSON...

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ...INSTALLATION AND START UP...

Страница 103: ...START UP PAPERS...

Страница 125: ...PROCESS AND CONTROL...

Страница 181: ...MECHANICAL AND FIELD INSTRUMENT COMPONENT INFORMATION...

Страница 182: ...ACTUATOR...

Страница 183: ...CORD SET...

Страница 185: ...AUMA...

Страница 186: ...115V 1ph 60Hz...

Страница 190: ...ANCHORS...

Страница 191: ...ADHESIVE ANCHOR See Drawing Section 7 for Details...

Страница 192: ...MANUAL GUN...

Страница 194: ...REFILL PACK...

Страница 197: ...MIXING NOZZLE...

Страница 199: ...INSTRUMENTATION...

Страница 200: ...CONTROLLER...

Страница 201: ...THERMO FISHER...

Страница 203: ...pH PROBE...

Страница 205: ...pH Probe Assembly Part 2966753 Sensor Head Data Stick Adapter 2012 11 28 2966753 pH Probe Assembly doc 2 of 2...

Страница 206: ...FLOW METER...

Страница 211: ...PRESSURE TRANSMITTER...

Страница 213: ...PUMP...

Страница 214: ...MEMBRANE FEED PUMP...

Страница 217: ...Pump Part 2616713 Gorman Rupp VG3B3 B Centrifugal 2013 12 09 2616713 Pump doc 3 of 3...

Страница 220: ...BACKWASH PUMP...

Страница 223: ...Pump Part 2616695 Gorman Rupp VG3C3 B Centrifugal 2013 12 09 2616695 Pump doc 3 of 3...

Страница 227: ...BUTTERFLY VALVE...

Страница 228: ...MANUAL LEVER BUTTERFLY VALVE...

Страница 238: ...ELECTRIC BUTTERFLY VALVE...

Страница 241: ...SWING CHECK VALVE...

Страница 243: ...SOLENOID VALVE...

Страница 245: ...MEMBRANE MODULE ACCESSORIES...

Страница 254: ...AIR COMPRESSOR ACCESSORIES...

Страница 258: ...ELECTRICAL CONTROL PANEL COMPONENT INFORMATION...

Страница 265: ...CABLE CONDUIT WIRE...

Страница 271: ...CIRCUIT BREAKER...

Страница 281: ...COMPUTER and MONITOR...

Страница 289: ...ENCLOSURE...

Страница 291: ...Type 12 Enclosure Part 2750002 Hoffman Two Door Floor Mount 2011 03 03 2750002 Hoffman Type 12 Enclosure doc 2 of 2...

Страница 293: ...Type 12 Enclosure Part 2750149 Hoffman Two Door Floor Mount 2007 07 09 2750149 Hoffman Type 12 Enclosure doc 2 of 2...

Страница 295: ...4X Fiberglass Enclosure Part 2750251 Hoffman ULTRX 2007 07 09 2750251 Hoffman 4X Fiberglass Enclosure doc 2 of 2...

Страница 296: ...ENCLOSURE ACCESSORIES...

Страница 307: ...ENVIRONMENTAL CONTROL ENCLOSURE...

Страница 310: ...Heat Exchanger Part 2752664 Hoffman XR472416012 2013 11 08 2752664 Heat Exchanger doc 2 of 3 Dimensions...

Страница 311: ...Heat Exchanger Part 2752664 Hoffman XR472416012 2013 11 08 2752664 Heat Exchanger doc 3 of 3 Cutout Dimensions...

Страница 313: ...Temperature Control Switch Part 2700943 Hoffman ATEMNO 2014 04 30 2700943 Hoffman Temperature Switch doc 2 of 2...

Страница 314: ...FUSE...

Страница 329: ...FUSE BLOCK...

Страница 336: ...HMI HUMAN MACHINE INTERFACE...

Страница 343: ...MAIN DISCONNECT...

Страница 350: ...MAIN DISCONNECT ACCESSORIES...

Страница 354: ...MOTOR CONTROL...

Страница 368: ...NETWORK...

Страница 374: ...Ethernet Switch Part 2702571 N TRON 708FX2 SC 2013 12 16 2702571 Ethernet Switch doc 3 of 3 Dimensions...

Страница 379: ...PILOT DEVICE...

Страница 392: ...PLC PROGRAMMABLE LOGIC CONTROL...

Страница 394: ...Analog Input Module Part 2701835 Allen Bradley CompactLogix 2008 01 30 2701835 AB Analog Input CompactLogix doc 2 of 3...

Страница 395: ...Analog Input Module Part 2701835 Allen Bradley CompactLogix 2008 01 30 2701835 AB Analog Input CompactLogix doc 3 of 3...

Страница 406: ...Power Supply Part 2701833 Allen Bradley CompactLogix 2008 01 11 2701833 AB Power Supply CompactLogix doc 2 of 2...

Страница 416: ...Flex I O Ethernet Adapter Part 2702281 Allen Bradley 2008 01 30 2702281 AB Flex IO Ethernet Module doc 2 of 4...

Страница 417: ...Flex I O Ethernet Adapter Part 2702281 Allen Bradley 2008 01 30 2702281 AB Flex IO Ethernet Module doc 3 of 4...

Страница 418: ...Flex I O Ethernet Adapter Part 2702281 Allen Bradley 2008 01 30 2702281 AB Flex IO Ethernet Module doc 4 of 4...

Страница 420: ...PRINTERS...

Страница 424: ...POWER SUPPLY...

Страница 426: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 2 of 5...

Страница 427: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 3 of 5...

Страница 428: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 4 of 5...

Страница 429: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 5 of 5...

Страница 431: ...Power Supply Part 2750761 DS 2750761 AB Power Supply doc 2 of 4 Copyright 2007 Aqua Aerobic Systems Inc 2013 01 14...

Страница 432: ...Power Supply Part 2750761 DS 2750761 AB Power Supply doc 3 of 4 Copyright 2007 Aqua Aerobic Systems Inc 2013 01 14...

Страница 433: ...Power Supply Part 2750761 DS 2750761 AB Power Supply doc 4 of 4 Copyright 2007 Aqua Aerobic Systems Inc 2013 01 14...

Страница 434: ...RELAY CONTROL...

Страница 436: ...Relay Part 2752020 Allen Bradley 700 HA32A1 4 2013 06 28 2752020 AB 700 HA34A1 4 Relay doc 2 of 3 Specifications...

Страница 440: ...SURGE SUPPRESSOR TRANSIENT FILTER...

Страница 442: ...Active Tracking Filter Part 2700906 Islatrol IC 105 2014 04 28 2700906 Islatrol Active Tracking Filter doc 2 of 2...

Страница 447: ...TERMINAL BLOCK ACCESSORIES...

Страница 471: ...TIMERS...

Страница 475: ...Relay Socket Part 2702163 ATC 2008 12 12 2702163 Delayed Interval Relay Socket doc 2 of 2 Wiring Diagram...

Страница 477: ...TRANSFORMER ACCESSORIES...

Страница 482: ...UPS UNINTERRUPTIBLE POWER SUPPLY...

Страница 489: ...MAINTENANCE AND TROUBLESHOOTING...

Страница 498: ...COMPONENT PRODUCTS EQUIPMENT O M INSTRUCTION MANUALS...

Страница 499: ...ACTUATOR...

Страница 500: ...ELECTRIC...

Страница 501: ...Electric part turn actuators Operation instructions SG 05 1 SG 12 1 SGR 05 1 SGR 12 1 AUMA NORM for flange type FA...

Страница 534: ...ADHESIVE ANCHOR O M...

Страница 535: ......

Страница 537: ...INSTRUMENTATION O M...

Страница 538: ...FLOW METER...

Страница 684: ...5 NOTES 30 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Страница 685: ...NOTES 5 31 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Страница 687: ......

Страница 688: ......

Страница 689: ......

Страница 690: ......

Страница 691: ......

Страница 692: ......

Страница 693: ......

Страница 694: ......

Страница 695: ......

Страница 696: ......

Страница 697: ......

Страница 698: ......

Страница 699: ......

Страница 700: ......

Страница 701: ......

Страница 702: ......

Страница 703: ......

Страница 704: ......

Страница 705: ......

Страница 706: ......

Страница 707: ......

Страница 708: ......

Страница 709: ......

Страница 710: ......

Страница 711: ......

Страница 712: ......

Страница 713: ......

Страница 714: ......

Страница 715: ......

Страница 716: ......

Страница 717: ......

Страница 718: ......

Страница 719: ......

Страница 720: ......

Страница 721: ......

Страница 722: ......

Страница 723: ...TURBIDITY MONITORING O M...

Страница 734: ...10 Installation Figure 4 1720E Dimensions...

Страница 738: ...14 System Startup...

Страница 746: ...22 Operation...

Страница 754: ...30 Troubleshooting...

Страница 760: ...36 Modbus Register Information...

Страница 762: ...38 Index...

Страница 763: ...DOC023 53 80221 FT660 sc 01 2012 Edition 2 User Manual...

Страница 764: ......

Страница 782: ...1 2 18 English...

Страница 783: ...3 4 English 19...

Страница 790: ...26 English...

Страница 791: ......

Страница 793: ...CONTROLLER...

Страница 794: ...Thermo Scientific AquaSensors AV38 Local Display and Controller User Guide...

Страница 873: ......

Страница 875: ...pH PROBE...

Страница 880: ...PRESSURE TRANSMITTER...

Страница 881: ......

Страница 900: ...A 9 Keller America Inc User s Guide Rev 10 11...

Страница 901: ...A 10 Keller America Inc User s Guide Rev 10 11...

Страница 904: ...MEMBRANE MODULE...

Страница 905: ...inge GmbH Installation Operation and Maintenance Guidelines inge T Rack vario...

Страница 934: ......

Страница 935: ...Appendix B Process Specification inge UF...

Страница 957: ...PUMPS...

Страница 958: ...GORMAN RUPP PUMP...

Страница 959: ......

Страница 960: ......

Страница 961: ......

Страница 962: ......

Страница 963: ......

Страница 964: ......

Страница 965: ......

Страница 966: ......

Страница 967: ......

Страница 968: ......

Страница 969: ......

Страница 970: ......

Страница 971: ......

Страница 972: ......

Страница 973: ......

Страница 974: ......

Страница 975: ......

Страница 976: ......

Страница 977: ......

Страница 978: ......

Страница 979: ......

Страница 980: ......

Страница 981: ......

Страница 982: ......

Страница 983: ......

Страница 984: ......

Страница 985: ......

Страница 986: ......

Страница 987: ......

Страница 988: ......

Страница 989: ......

Страница 990: ......

Страница 991: ......

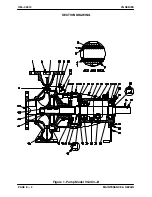

Страница 1013: ...OM 02812 VG SERIES MAINTENANCE REPAIR PAGE E 2 SECTION DRAWING PARTSPAGE Figure 1 Pump Model VG3C3 B...

Страница 1056: ...VALVES...

Страница 1057: ...NIBCO VALVE...

Страница 1058: ...WAFER BUTTERFLY VALVE...

Страница 1068: ...MILLIKEN VALVE...

Страница 1069: ...MILLIKEN BUTTERFLY VALVE...

Страница 1070: ......

Страница 1075: ...5 OPERATION MAINTENANCE ILLUSTRATION 3 Q DIMENSION 3 4 6 8 10 12 14 16 18 20 24 2 75 4 88 5 57 8 38 10 5 13 13 15 25 17 38 21 38...

Страница 1077: ...MECHANICAL DRAWINGS...

Страница 1110: ...ELECTRICAL DRAWINGS...

Страница 1119: ......

Страница 1153: ......

Страница 1157: ......