HI-BUILD EPOXOLINE II

PRODUCT DATA SHEET

N69 or V69

PRODUCT PROFILE

GENERIC DESCRIPTION

Polyamidoamine Epoxy

COMMON USAGE

An advanced generation epoxy for protection and finishing of steel and concrete. It has excellent resistance to abrasion

and is suitable for immersion as well as chemical contact exposure. Contact your local Tnemec representative for a list of

chemicals. This product can also be used for lining storage tanks that contain demineralized, deionized or distilled water.

Note: Series V69 conforms with air pollution regulations limiting Volatile Organic Compounds (VOC) to a maximum of

250 grams/litre (2.08 lbs/gal) in areas requiring less than 100 grams/litre VOC, please refer to the Series L69 data sheet.

COLORS

Refer to Tnemec Color Guide. Note: Epoxies chalk with extended exposure to sunlight. Lack of ventilation, incomplete

mixing, miscatalyzation or the use of heaters that emit carbon dioxide and carbon monoxide during application and initial

stages of curing may cause yellowing to occur.

FINISH

Satin

SPECIAL QUALIFICATIONS

A two-coat system at 4.0-6.0 dry mills (100-150 dry microns) per coat passes the performance requirements of MIL-PRF-

4556F for fuel storage.

PERFORMANCE CRITERIA

Extensive test data available. Contact your Tnemec representative for specific test results.

Published technical data and instructions are subject to change without notice. The online catalog at www.tnemec.com

should be referenced for the most current technical data and instructions or you may contact your Tnemec representative

for current technical data and instructions.

© May 14, 2010 by Tnemec Co., Inc.

COATING SYSTEM

PRIMERS

Steel: Self-priming or Series 1, 27, 37H, 66, 90E-92, 90-97, 90-1K97, 91-H

2

O, 94-H

2

O, 135, 161, 394, 530

Galvanized Steel and Non-Ferrous Metal: Self-priming or Series 66, 161

Concrete: Self-priming or Series 130, 218

CMU: Self-priming or 54-562, 130, 215, 216, 218

TOPCOATS

46H-413, 66, L69, N69, 73, 84, 104, 113, 114, 161, 175, 1028, 1029, 1070, 1071, 1072, 1074, 1074U, 1075, 1075U, 1077,

1078. Refer to COLORS on applicable topcoat data sheets for additional information. Note: The following recoat times

apply for Series N69/V69: Immersion Service—Surface must be scarified after 60 days. Atmospheric Service—After 60

days, scarification or an epoxy tie-coat is required. Contact your Tnemec representative for specific recommendations.

Published technical data and instructions are subject to change without notice. The online catalog at www.tnemec.com

should be referenced for the most current technical data and instructions or you may contact your Tnemec representative

for current technical data and instructions.

SURFACE PREPARATION

PRIMED STEEL

Immersion Service: Scarify the Series 66, N69/V69 or 161 prime coat surface by abrasive blasting with fine abrasive before

topcoating if it has been exterior exposed for 60 days or longer and N69/V69 is the specified topcoat.

STEEL

Immersion Service: SSPC-SP10/NACE 2 Near-White Blast Cleaning

Non-Immersion Service: SSPC-SP6/NACE 3 Commercial Blast Cleaning

GALVANIZED STEEL & NON-

FERROUS METAL

Surface preparation recommendations will vary depending on substrate and exposure conditions. Contact your Tnemec

representative or Tnemec Technical Services.

CAST/DUCTILE IRON

Contact your Tnemec representative or Tnemec Technical Services.

CONCRETE

Allow new concrete to cure 28 days. For optimum results and/or immersion service, abrasive blast referencing SSPC-

SP13/NACE 6, ICRI CSP 2-4 Surface Preparation of Concrete and Tnemec’s Surface Preparation and Application Guide.

CMU

Allow mortar to cure for 28 days. Level protrusions and mortar spatter.

PAINTED SURFACES

Non-Immersion Service: Ask your Tnemec representative for specific recommendations.

ALL SURFACES

Must be clean, dry and free of oil, grease, chalk and other contaminants.

Published technical data and instructions are subject to change without notice. The online catalog at www.tnemec.com

should be referenced for the most current technical data and instructions or you may contact your Tnemec representative

for current technical data and instructions.

TECHNICAL DATA

VOLUME SOLIDS

67.0 ± 2.0% (mixed) †

RECOMMENDED DFT

2.0 to 10.0 mils (50 to 255 microns) per coat. Note: MIL-PRF-4556F applications require two coats at 4.0-6.0 mils (100-150

microns) per coat. Otherwise, the number of coats and thickness requirements will vary with substrate, application

method and exposure. Contact your Tnemec representative.

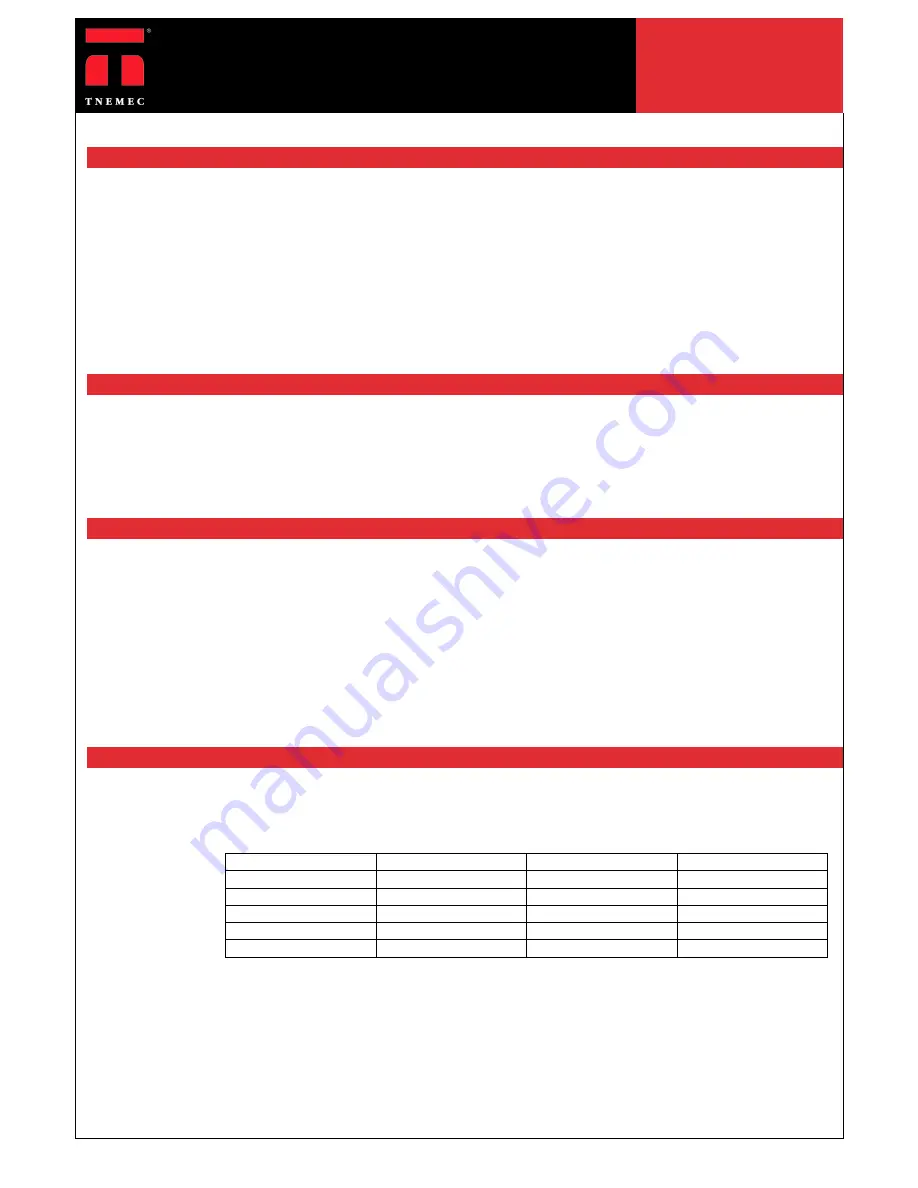

CURING TIME AT 5 MILS DFT

Without 44-700 Accelerator

Temperature

To Handle

To Recoat

Immersion

90°F (32°C)

4 hours

7 hours

6 days

80°F (27°C)

5 hours

8 hours

7 days

70°F (21°C)

7 hours

10 hours

7 days

60°F (16°C)

8 hours

12 hours

9 days

50°F (10°C)

12 hours

16 hours

12 days

Curing time varies with surface temperature, air movement, humidity and film thickness. Note: For faster curing and low-

temperature applications, add No. 44-700 Epoxy Accelerator; see separate product data sheet.

VOLITILE ORGANIC COMPOUNDS

N69 - Unthinned: 2.40 lbs/gallon (285 grams/litre)

Thinned 10% (No. 4 Thinner): 2.80 lbs/gallon (334 grams/litre)

Thinned 10% (No. 60 Thinner): 2.80 lbs/gallon (335 grams/litre)

V69 - Unthinned: 1.95 lbs/gallon (234 grams/litre)

Thinned 2.5%: 2.08 lbs/gallon (250 grams/litre) †

HAPS

N69 - Unthinned: 2.40 lbs/gal solids

Thinned 10% (No. 4 Thinner): 3.25 lbs/gal solids

Thinned 10% (No. 60 Thinner): 2.40 lbs/gal solids

V69 - Unthinned: 2.05 lbs/gal solids

Thinned 2.5%: 2.30 lbs/gal solids)

THEORETICAL COVERAGE

1,074 mil sq ft/gal (26.4 m²/L at 25 microns). See APPLICATION for coverage rates. †

Page 1 of 2

Содержание VG3B3-B

Страница 14: ...GENERAL INFORMATION...

Страница 17: ...EQUIPMENT SAFETY DOCUMENTS and PRECAUTIONS...

Страница 30: ...U L MOTOR REQUIREMENTS...

Страница 31: ......

Страница 35: ...PROTECTIVE COATINGS...

Страница 37: ...PAINT TECHNICAL DATA SHEETS...

Страница 43: ...PASSIVATION DOCUMENTS...

Страница 47: ...STORAGE PROCEDURES...

Страница 51: ...INSTRUMENTATION...

Страница 56: ...VALVES...

Страница 58: ...PUMPS...

Страница 61: ...MATERIAL SAFETY DATA SHEETS...

Страница 65: ......

Страница 66: ...PAINT COATING MSDS...

Страница 73: ...ADHESIVE ANCHORS MSDS...

Страница 74: ...SIMPSON...

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ...INSTALLATION AND START UP...

Страница 103: ...START UP PAPERS...

Страница 125: ...PROCESS AND CONTROL...

Страница 181: ...MECHANICAL AND FIELD INSTRUMENT COMPONENT INFORMATION...

Страница 182: ...ACTUATOR...

Страница 183: ...CORD SET...

Страница 185: ...AUMA...

Страница 186: ...115V 1ph 60Hz...

Страница 190: ...ANCHORS...

Страница 191: ...ADHESIVE ANCHOR See Drawing Section 7 for Details...

Страница 192: ...MANUAL GUN...

Страница 194: ...REFILL PACK...

Страница 197: ...MIXING NOZZLE...

Страница 199: ...INSTRUMENTATION...

Страница 200: ...CONTROLLER...

Страница 201: ...THERMO FISHER...

Страница 203: ...pH PROBE...

Страница 205: ...pH Probe Assembly Part 2966753 Sensor Head Data Stick Adapter 2012 11 28 2966753 pH Probe Assembly doc 2 of 2...

Страница 206: ...FLOW METER...

Страница 211: ...PRESSURE TRANSMITTER...

Страница 213: ...PUMP...

Страница 214: ...MEMBRANE FEED PUMP...

Страница 217: ...Pump Part 2616713 Gorman Rupp VG3B3 B Centrifugal 2013 12 09 2616713 Pump doc 3 of 3...

Страница 220: ...BACKWASH PUMP...

Страница 223: ...Pump Part 2616695 Gorman Rupp VG3C3 B Centrifugal 2013 12 09 2616695 Pump doc 3 of 3...

Страница 227: ...BUTTERFLY VALVE...

Страница 228: ...MANUAL LEVER BUTTERFLY VALVE...

Страница 238: ...ELECTRIC BUTTERFLY VALVE...

Страница 241: ...SWING CHECK VALVE...

Страница 243: ...SOLENOID VALVE...

Страница 245: ...MEMBRANE MODULE ACCESSORIES...

Страница 254: ...AIR COMPRESSOR ACCESSORIES...

Страница 258: ...ELECTRICAL CONTROL PANEL COMPONENT INFORMATION...

Страница 265: ...CABLE CONDUIT WIRE...

Страница 271: ...CIRCUIT BREAKER...

Страница 281: ...COMPUTER and MONITOR...

Страница 289: ...ENCLOSURE...

Страница 291: ...Type 12 Enclosure Part 2750002 Hoffman Two Door Floor Mount 2011 03 03 2750002 Hoffman Type 12 Enclosure doc 2 of 2...

Страница 293: ...Type 12 Enclosure Part 2750149 Hoffman Two Door Floor Mount 2007 07 09 2750149 Hoffman Type 12 Enclosure doc 2 of 2...

Страница 295: ...4X Fiberglass Enclosure Part 2750251 Hoffman ULTRX 2007 07 09 2750251 Hoffman 4X Fiberglass Enclosure doc 2 of 2...

Страница 296: ...ENCLOSURE ACCESSORIES...

Страница 307: ...ENVIRONMENTAL CONTROL ENCLOSURE...

Страница 310: ...Heat Exchanger Part 2752664 Hoffman XR472416012 2013 11 08 2752664 Heat Exchanger doc 2 of 3 Dimensions...

Страница 311: ...Heat Exchanger Part 2752664 Hoffman XR472416012 2013 11 08 2752664 Heat Exchanger doc 3 of 3 Cutout Dimensions...

Страница 313: ...Temperature Control Switch Part 2700943 Hoffman ATEMNO 2014 04 30 2700943 Hoffman Temperature Switch doc 2 of 2...

Страница 314: ...FUSE...

Страница 329: ...FUSE BLOCK...

Страница 336: ...HMI HUMAN MACHINE INTERFACE...

Страница 343: ...MAIN DISCONNECT...

Страница 350: ...MAIN DISCONNECT ACCESSORIES...

Страница 354: ...MOTOR CONTROL...

Страница 368: ...NETWORK...

Страница 374: ...Ethernet Switch Part 2702571 N TRON 708FX2 SC 2013 12 16 2702571 Ethernet Switch doc 3 of 3 Dimensions...

Страница 379: ...PILOT DEVICE...

Страница 392: ...PLC PROGRAMMABLE LOGIC CONTROL...

Страница 394: ...Analog Input Module Part 2701835 Allen Bradley CompactLogix 2008 01 30 2701835 AB Analog Input CompactLogix doc 2 of 3...

Страница 395: ...Analog Input Module Part 2701835 Allen Bradley CompactLogix 2008 01 30 2701835 AB Analog Input CompactLogix doc 3 of 3...

Страница 406: ...Power Supply Part 2701833 Allen Bradley CompactLogix 2008 01 11 2701833 AB Power Supply CompactLogix doc 2 of 2...

Страница 416: ...Flex I O Ethernet Adapter Part 2702281 Allen Bradley 2008 01 30 2702281 AB Flex IO Ethernet Module doc 2 of 4...

Страница 417: ...Flex I O Ethernet Adapter Part 2702281 Allen Bradley 2008 01 30 2702281 AB Flex IO Ethernet Module doc 3 of 4...

Страница 418: ...Flex I O Ethernet Adapter Part 2702281 Allen Bradley 2008 01 30 2702281 AB Flex IO Ethernet Module doc 4 of 4...

Страница 420: ...PRINTERS...

Страница 424: ...POWER SUPPLY...

Страница 426: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 2 of 5...

Страница 427: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 3 of 5...

Страница 428: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 4 of 5...

Страница 429: ...Power Supply Part 2751312 Allen Bradley 2008 02 28 2751312 AB Power Supply doc 5 of 5...

Страница 431: ...Power Supply Part 2750761 DS 2750761 AB Power Supply doc 2 of 4 Copyright 2007 Aqua Aerobic Systems Inc 2013 01 14...

Страница 432: ...Power Supply Part 2750761 DS 2750761 AB Power Supply doc 3 of 4 Copyright 2007 Aqua Aerobic Systems Inc 2013 01 14...

Страница 433: ...Power Supply Part 2750761 DS 2750761 AB Power Supply doc 4 of 4 Copyright 2007 Aqua Aerobic Systems Inc 2013 01 14...

Страница 434: ...RELAY CONTROL...

Страница 436: ...Relay Part 2752020 Allen Bradley 700 HA32A1 4 2013 06 28 2752020 AB 700 HA34A1 4 Relay doc 2 of 3 Specifications...

Страница 440: ...SURGE SUPPRESSOR TRANSIENT FILTER...

Страница 442: ...Active Tracking Filter Part 2700906 Islatrol IC 105 2014 04 28 2700906 Islatrol Active Tracking Filter doc 2 of 2...

Страница 447: ...TERMINAL BLOCK ACCESSORIES...

Страница 471: ...TIMERS...

Страница 475: ...Relay Socket Part 2702163 ATC 2008 12 12 2702163 Delayed Interval Relay Socket doc 2 of 2 Wiring Diagram...

Страница 477: ...TRANSFORMER ACCESSORIES...

Страница 482: ...UPS UNINTERRUPTIBLE POWER SUPPLY...

Страница 489: ...MAINTENANCE AND TROUBLESHOOTING...

Страница 498: ...COMPONENT PRODUCTS EQUIPMENT O M INSTRUCTION MANUALS...

Страница 499: ...ACTUATOR...

Страница 500: ...ELECTRIC...

Страница 501: ...Electric part turn actuators Operation instructions SG 05 1 SG 12 1 SGR 05 1 SGR 12 1 AUMA NORM for flange type FA...

Страница 534: ...ADHESIVE ANCHOR O M...

Страница 535: ......

Страница 537: ...INSTRUMENTATION O M...

Страница 538: ...FLOW METER...

Страница 684: ...5 NOTES 30 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Страница 685: ...NOTES 5 31 IFC 100 www krohne com 07 2010 4000124104 QS IFC 100 R04 en...

Страница 687: ......

Страница 688: ......

Страница 689: ......

Страница 690: ......

Страница 691: ......

Страница 692: ......

Страница 693: ......

Страница 694: ......

Страница 695: ......

Страница 696: ......

Страница 697: ......

Страница 698: ......

Страница 699: ......

Страница 700: ......

Страница 701: ......

Страница 702: ......

Страница 703: ......

Страница 704: ......

Страница 705: ......

Страница 706: ......

Страница 707: ......

Страница 708: ......

Страница 709: ......

Страница 710: ......

Страница 711: ......

Страница 712: ......

Страница 713: ......

Страница 714: ......

Страница 715: ......

Страница 716: ......

Страница 717: ......

Страница 718: ......

Страница 719: ......

Страница 720: ......

Страница 721: ......

Страница 722: ......

Страница 723: ...TURBIDITY MONITORING O M...

Страница 734: ...10 Installation Figure 4 1720E Dimensions...

Страница 738: ...14 System Startup...

Страница 746: ...22 Operation...

Страница 754: ...30 Troubleshooting...

Страница 760: ...36 Modbus Register Information...

Страница 762: ...38 Index...

Страница 763: ...DOC023 53 80221 FT660 sc 01 2012 Edition 2 User Manual...

Страница 764: ......

Страница 782: ...1 2 18 English...

Страница 783: ...3 4 English 19...

Страница 790: ...26 English...

Страница 791: ......

Страница 793: ...CONTROLLER...

Страница 794: ...Thermo Scientific AquaSensors AV38 Local Display and Controller User Guide...

Страница 873: ......

Страница 875: ...pH PROBE...

Страница 880: ...PRESSURE TRANSMITTER...

Страница 881: ......

Страница 900: ...A 9 Keller America Inc User s Guide Rev 10 11...

Страница 901: ...A 10 Keller America Inc User s Guide Rev 10 11...

Страница 904: ...MEMBRANE MODULE...

Страница 905: ...inge GmbH Installation Operation and Maintenance Guidelines inge T Rack vario...

Страница 934: ......

Страница 935: ...Appendix B Process Specification inge UF...

Страница 957: ...PUMPS...

Страница 958: ...GORMAN RUPP PUMP...

Страница 959: ......

Страница 960: ......

Страница 961: ......

Страница 962: ......

Страница 963: ......

Страница 964: ......

Страница 965: ......

Страница 966: ......

Страница 967: ......

Страница 968: ......

Страница 969: ......

Страница 970: ......

Страница 971: ......

Страница 972: ......

Страница 973: ......

Страница 974: ......

Страница 975: ......

Страница 976: ......

Страница 977: ......

Страница 978: ......

Страница 979: ......

Страница 980: ......

Страница 981: ......

Страница 982: ......

Страница 983: ......

Страница 984: ......

Страница 985: ......

Страница 986: ......

Страница 987: ......

Страница 988: ......

Страница 989: ......

Страница 990: ......

Страница 991: ......

Страница 1013: ...OM 02812 VG SERIES MAINTENANCE REPAIR PAGE E 2 SECTION DRAWING PARTSPAGE Figure 1 Pump Model VG3C3 B...

Страница 1056: ...VALVES...

Страница 1057: ...NIBCO VALVE...

Страница 1058: ...WAFER BUTTERFLY VALVE...

Страница 1068: ...MILLIKEN VALVE...

Страница 1069: ...MILLIKEN BUTTERFLY VALVE...

Страница 1070: ......

Страница 1075: ...5 OPERATION MAINTENANCE ILLUSTRATION 3 Q DIMENSION 3 4 6 8 10 12 14 16 18 20 24 2 75 4 88 5 57 8 38 10 5 13 13 15 25 17 38 21 38...

Страница 1077: ...MECHANICAL DRAWINGS...

Страница 1110: ...ELECTRICAL DRAWINGS...

Страница 1119: ......

Страница 1153: ......

Страница 1157: ......