STEP 2 - HANGER INSTALLATION

Top Hanger Assemblies

2.1

Mark top hanger placement on the building support

beams and runway/monorail track (refer to the

General

Arrangement Drawing

, inserted in this manual, for

hanger placement). Installation parameters can be

found on page 22.

2.2

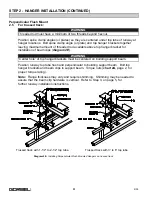

To attach threaded rod to top hanger bracket:

Assemble top hanger assembly (

diagram 2A

). Refer to

Chart 2A

for proper nut torque.

2.3

Bolt top hanger bracket assembly and beam clips to building support beam

(

diagram 2B

).

Note

:

Flange thickness may vary and require shimming. Shimming

may be needed to assure that the beam clip hardware is vertical.

TIP:

Standard top hanger brackets are designed for flange

widths from 1”-3”, 3-1/4”-5-1/4”, 5-1/2”-7-1/2”, 8”-10”.

WARNING

Threaded rod must have a minimum of two threads

beyond the hexnut.

Chart 2A.

Torque Chart.

4000#

250-2000#

Diagram 2A.

Attaching threaded rod to top hanger bracket.

WARNING

250-2000#

4000#

Diagram 2B.

Bolting top hanger bracket and beam clips to existing support beam.

2

9/05

“Center hole” of the top hanger bracket assembly must be centered on building support

beam.

Æ

Bridge Crane

Monorail

Bolt Diameter

1/2”

5/8”

3/4”

Torque

50 ft.-lb.

95 ft.-lb.

150 ft.lb.

TORQUE CHART

Содержание AL 1000

Страница 1: ......