STEP 6 - HOIST TROLLEY INSTALLATION (CONTINUED)

Loadbar Hoist Trolley, 4000# Steel / 2000# - 4000# Aluminum

6.15

Clean inside flanges of track with a clean, dry cloth (

do

not use any kind of cleaning solution

) to remove grit

or debris that may have collected during shipping,

storage, or installation.

6.16

Be sure end stop is installed opposite the festooning end

of bridge/monorail.

6.17

Bend

both legs

of all cotter pins (

diagram 6F

).

6.18

Attach hoist to hoist trolley by snapping hoist suspension hook over the clevis bolt (center

bolt) on hoist trolley loadbar.

6.19

If hoist suspension hook is too large or hoist has a suspension device other than a hook,

you will need to remove clevis bolt and install suspension device (by others). Insert clevis

bolt back into place. Place nylock nut on end of bolt and tighten (

diagram 6G

).

6.20

Roll hoist trolley into open end of track on bridge/monorail.

6.21

Install end stop on festooning end of bridge/monorail (

diagram 3C

, on page 6).

6.22

If you

do not

have festooning, go to Step 9, on page 21.

If you

do not

have a festoon stack section, go to Step 8, on page 18.

Otherwise go to Step 7, on page 17.

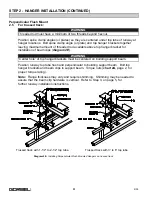

Diagram 6F.

Installing cotter pin

through trolley saddle clevis pin.

WARNING

Fully bend both legs of cotter pin (

diagram 6F

).

If cotter pin is cracked or fatigued it

must be replaced.

WARNING

Hang hoist from clevis bolt (center bolt) of hoist trolley only.

WARNING

Be sure to tighten nut on the clevis bolt (center bolt) of hoist trolley.

Do not “over-

tighten” nylock nut:

could cause damage to trolleys. Nylock nut on clevis bolt should

only be used once. If this item is disassembled, then nut must be replaced.

Diagram 6G.

Installing hoist on loadbar hoist trolley.

16

9/05

Содержание AL 1000

Страница 1: ......