STEP 5 - BRIDGE AND END TRUCK INSTALLATION (CONTINUED)

Standard End Trucks (continued)

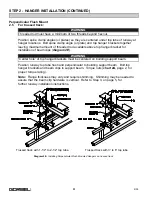

250# - 500# Aluminum Bridges

5.7

Slide an end truck over festooning end of

bridge (refer to the

General Arrangement

Drawing

for exact end truck location) and

clamp into place (

diagram 5B

).

Note:

The festooning end of the bridge will

have a hole that is inset the same or greater

distance from the end of the bridge than the

hole in the opposite end of the bridge.

5.8

Slide and position the non-clamping end

truck on the other end of bridge (refer to the

General Arrangement Drawing

for exact

location).

5.9

Go to Step 5.12.

1000# - 2000# Aluminum Bridges & 250# - 500# Coped Aluminum Bridges

5.10

Slide an end truck over coped brackets on the

festooning end of bridge (refer to the

General

Arrangement Drawing

for exact end truck

location) and clamp into place (

diagram 5C

).

Note:

The festooning end of the bridge will have

an end stop hole that is inset the same or greater

distance from the end of the bridge than the end

stop hole in the opposite end of the bridge.

5.11

Slide and position the non-clamping end truck on

the other end of bridge (refer to the

General

Arrangement Drawing

for exact location).

5.12

At both ends of bridge, install a shear lug bolt in

hole at top of bridge (or in the coped brackets)

to prevent bridge from sliding out of end trucks

(

diagrams 5B & 5C

).

Note:

Install bolts with head of bolt on

underside

of top flange with threads pointing up.

5.13

If a tow arm is not

being utilized on the end truck, go to Step 5.37, on page 13.

If a tow arm is

being utilized on the end truck, go to Step 5.14, on page 10.

Note:

Festoon tow arms are

not

recommended for use on 4000# systems or systems

with extended end trucks. They are

not necessary

on systems with festoon trolleys.

TIP:

ONLY ONE

end truck is clamped to the bridge: the other is not. The clamping end truck

must be oriented with the festooning side of the track (refer to Step 8, on page 18 for

festooning). The non-clamping end truck allows adjustment for any runway misalignment.

TIP:

Make sure nylon spacers are attached to end truck before installing end truck on bridge.

Æ

Æ

Æ

Diagram 5B.

Installing clamping end truck on aluminum

bridge. See

TIP.

Diagram 5C.

Installing clamping end truck on

coped aluminum bridge. See

TIP

.

Æ

WARNING

Failure to install shear lug bolt assemblies may result in the bridge, hoist, and load falling

to the floor.

9

9/05

Содержание AL 1000

Страница 1: ......