STEP 5 - BRIDGE AND END TRUCK INSTALLATION

5.1

Make sure end stops have been installed in the runway

end opposite the festooning (leaving festooning end open

for bridge installation).

5.2

Prior to adding bridge, clean inside flanges of track with

clean, dry cloth (

do not use any kind of cleaning

solution

) to remove grit or debris that may have collected

during shipping, storage, or installation.

5.3

If your end trucks look like:

Standard End Trucks

250# - 2000# Steel Bridges

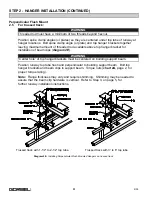

5.4

Slide an end truck over festooning end of

bridge (refer to the

General Arrangement

Drawing

for exact end truck location, end

truck sleeve should be 1” from first

vertical) and clamp into place with

hardware provided (

diagram 5A

).

Note:

The festooning end of the bridge

will have a hole that is inset the same or

greater distance from the end of the

bridge than the hole in the opposite end

of the bridge.

5.5

Slide and position the non-clamping end

truck on the other end of bridge (refer to

the

General Arrangement Drawing

for

exact location, end truck sleeve should

be 1” from first vertical).

5.6

Go to Step 5.37, on page 13.

TIP:

ONLY ONE

end truck is clamped to the bridge: the

other is not. The clamping end truck must be oriented

with the festooning side of the track (refer to Step 8,

on page 18 for festooning). The non-clamping end truck

allows adjustment for any runway misalignment.

Æ

(Shipped Assembled)

go to Step 5.4

(Shipped Assembled)

go to Step 5.7

(Shipped Unassembled)

go to Step 5.17

(Shipped Unassembled)

go to Step 5.27

Diagram 5A.

Installing standard clamping end truck.

See

TIP

.

Æ

8

9/05

Bridge Crane

Содержание AL 1000

Страница 1: ......