STEP 5 - BRIDGE AND END TRUCK INSTALLATION (CONTINUED)

Extended End Trucks (continued)

5.20

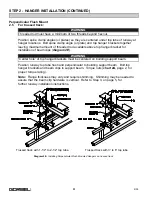

Place a wheel plate between the end truck

tubes. Insert 1” dia. bolt into first tube,

through the wheel plate and out the

opposite tube (

diagram 5H

).

5.21

Place nylock nut on end of bolt and tighten

snug against extended end truck tube.

Note:

Wheel plates should pivot freely.

5.22

Repeat steps 5.20 and 5.21 for remaining wheel plate.

5.23

Repeat steps 5.17 to 5.22 for remaining extended end trucks.

5.24

Slide an end truck over festooning end

of bridge (refer to the

General

Arrangement Drawing

for exact end

truck location, end truck sleeve should

be 1” from first vertical) and clamp into

place (

diagram 5I

).

Note:

The festooning end of the bridge

will have a hole that is inset the same

or greater distance from the end of the

bridge than the hole in the opposite

end of the bridge.

5.25

Slide and position the non-clamping end

truck on the other end of bridge (refer to

the

General Arrangement Drawing

for

exact location, end truck sleeve should be

1” from first vertical).

5.26

Go to Step 5.37, on page 13.

TIP:

ONLY ONE

end truck is clamped to the bridge: the other is not. The clamping end truck

must be oriented with the festooning side of the track (refer to Step 8, on page 18 for

festooning). The non-clamping end truck allows adjustment for any runway misalignment.

TIP:

Extended end truck should be assembled before attaching to bridge.

Æ

Æ

Diagram 5I.

Installing extended clamping end truck.

See

TIP.

11

9/05

Diagram 5H.

Installing wheel plates.

WARNING

Do not “over-tighten”

nylock nut: could

cause damage to end trucks. Nylock nut

can only be used once. If this item is

disassembled, then nut must be replaced.

Содержание AL 1000

Страница 1: ......