CONSOLE TECHNICAL OVERVIEW

ENGLISH

Topic Title

H-7

Testing

Testing Temperature Sensors

The easiest problems to solve will involve codes that are

related to potential failure of temperature sensors. Common

problems may include loose connections, open electrically,

and out of calibration. Checking the condition of the sensors

requires a temperature probe and an ohmmeter.

The Reference Section of this manual contains temperature

resistance tables that can be used to check the calibration

of the sensors. The measured resistance must be within the

tolerances printed on the top of the tables.

To test the electrical condition of a temperature sensor

perform the following:

1.

Confirm the sensor is firmly attached to the circuit board

connection plug.

2. Remove the sensor wires form the connection plug by

releasing holding tension on the plugs tension tab.

3. Use an ohmmeter to test the electrical resistance of the

sensor.

4. Measure the air temperature near the sensor and compare

the required resistance against measured resistance.

(See chart in reference section) If the sensor is within

calibration, the sensor is good. If the sensor is out of

calibration, replace the sensor. (Tube Sensors should be

removed from socket and exposed to air temperature

during test.)

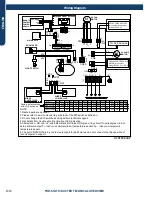

2

4

USYF09UCDWA1

Note

:

1.Dashed parts are optional.

2.Please refer to the technical service manual for detailed explanations

of DIP switches.

3.Do not change the DIP switches setting without technical support

4.Abbreviation

:

R-red ,B-black,BL-blue,W-white,Y/G-yellow/green,

TEMP.-temperature, E.A.O-exrernal alarm output,Tr-indoor unit

room temperature sensor ,Tp-indoor unit pipe temperature sensor (coil

temperature sensor)

Wired controller

display(YR-E17)

07 flashing on the

upper right corner

Outdoor error code

+20 correspond

HEX code

Tp Tr

SW1-1

OFF OFF

SW1-2

OFF OFF OFF OFF

OFF OFF

OFF

OFF OFF OFF OFF

OFF OFF

ON

OFF OFF OFF OFF

OFF OFF

OFF

ON

SW1-3 SW1-4 SW1-5 SW1-6 SW1-7 SW1-8

To Outdoor Unit

All Console

default

MODEL

DIP switches factory default setting

L2 L1

Note:

SW1

LED5

LED4

250V

AC T5A

FUSE

CN20

CN22(22-1)

CN31

CN1

1

CN35

Main control board

Swing motor

for lower

louver

Swing motor

for upper

louver

CN10

CN6

CN3

CN17

SW2

CN16

CN16-1

W

B

W

BL

BL

W

W

W

YL

BL

W

W

Panel

display

RJ45 BOARD

To RJ45 DEVICE

SW3-1 SW3-2 SW3-3 SW3-4 SW3-5 SW3-6 SW3-7 SW3-8

USYF12UCDWA1

USYF18UCDWA1

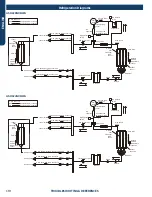

Testing Louver Motors

If the louver does not operate with command from the remote

control, either the indoor board is bad, or the louver motor

is defective. It is more likely the motor is defective than the

board. (Make sure the louver assembly is not binding and

keeping the vanes from moving.)

1. Remove power from the unit and remove the indoor unit

cover.

2. Access the circuit board.

3. Identify the inoperable louver motor on the schematic

drawing below and disconnect the plug from the circuit

board.

4. Use an Ohmmeter to test the electrical continuity of the

louver motor windings. The proper resistance for each

winding should be 292Ω from red wire (common) to any

other wire.. If the motor winding resistance is erratic or

shows open, the motor is defective. Replace the motor.

5. If the motor checks out good, replace the indoor control

board.

Upper Louver

Lower Louver

Содержание AB09SC2VHA

Страница 2: ...Oct 2020 Manual release Revision History ...

Страница 12: ... This page intentionally left blank ...

Страница 45: ...WALL MOUNT TECHNICAL OVERVIEW ENGLISH Topic Title C 9 Wiring Diagrams ...

Страница 68: ... This page intentionally left blank ...

Страница 78: ... This page intentionally left blank ...

Страница 104: ... This page intentionally left blank ...