OUTDOOR TECHNICAL OVERVIEW

ENGLISH

Topic Title

B-18

Testing

Variable Speed Compressor

1.

Begin by turning off power at the equipment disconnect switch. Adequate time must be given for capacitors on the circuit

board to discharge. Wait a minimum of 12 minutes before handling the circuitry.

2. Locate the Inverter control module (IPM). The IPM is connected to the main circuit board by a wire harnesses, and has the

compressor connections mounted on it.

3. Set your test meter to AC volts and test for voltage at the three compressor connections. Voltage should be zero before

proceeding.

4. Remove the three compressor connections making note of the terminal letter and the wire colors.

5. Set your ohm meter to the lowest resistance setting that is available. Test all three connections terminals using the following

sequence:

• U terminal to V terminal

• U terminal to W terminal

• V terminal to W terminal

All three resistance values should match the specification table below. Compressor windings are deemed bad if they are

greater than 7% out of specification. Readings taken at the wire IPM module that are outside of factory tolerances require

steps 6 through 9.

6. Remove the compressor blanket and set it aside. Remove the terminal block cover to expose the connections at the

compressor terminals. Inspect for any visual damage. Remove all three wires from the terminals making note of the wire color

and the terminal identifier.

7. Repeat process outlined in step 5. Repair or replace the wires if the compressor windings check properly.

8. Check each terminal to ground (suction line connection at compressor) to check for grounded windings if the resistance

values are not correct.

9.

Replace the compressor if the winding measurements are greater than 7% out of specification.

Wiring Error Check

1. Disconnect power to

the outdoor unit.

2. Set Dip Switches

SW1-1, SW1-2,

SW1-3 & SW1-4 to

the ON position.

These dip switches

are located on the

Service Monitor

Board.

3. Turn ON power to the outdoor unit.

4. All indoor fans will be set to HIGH fan speed.

5. EEV for Circuit A will open. All other EEV’s will close.

6. After a 3 minute delay, the Compressor will start and ramp

up to 55HZ.

7. The digital display with alternately display “CH” and

“Compressor Frequency (HZ)” at 5 second intervals

8. The system will circulate refrigerant through Circuit A for

approximatley 10 minutes.

9. Afterwards, Circuit A’s EEV will close and Circuit B’s EVV

will open.

10. This process will be repeated for each indoor unit that is

connected.

11. Once all indoor units have

been checked, the digital

display will display either

“EC” or “0”. “EC” indicates

a communication error

between the outdoor and

indoor unit. The LED(s) will

be flashing, indicating which

circuit has the fault

12.

Once the wiring is corrected, re-run this test to confirm

everything is functional.

13. “0” indicates that all wiring is

correct.

14. If all wiring is correct, the

LED’s remain solid lit.

15. Once the test is complete,

make sure to change the dip

switches back to the OFF

position, and set each indoor

unit to preferred set points.

Содержание AB09SC2VHA

Страница 2: ...Oct 2020 Manual release Revision History ...

Страница 12: ... This page intentionally left blank ...

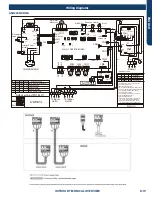

Страница 45: ...WALL MOUNT TECHNICAL OVERVIEW ENGLISH Topic Title C 9 Wiring Diagrams ...

Страница 68: ... This page intentionally left blank ...

Страница 78: ... This page intentionally left blank ...

Страница 104: ... This page intentionally left blank ...