5

Foundation depth depends on the ground and

pier weight. Gate width is critical, so it is safer to

lay the first brick course before ordering the gate

to ensure it fits.

The casements can now be laid on a thin bed of

concrete over the concrete base. Fig7 shows an

alternative method where the casements are

suspended from a level bar resting on the first

few brick courses. This ensures the casements

are level and packed underneath.

Push fit ducts and drains in the casement.

Protect any exposed screw threads and tape up

any holes to prevent concrete ingress. Then

build concrete around the casement to at least

75mm, including under the pivot shelf.

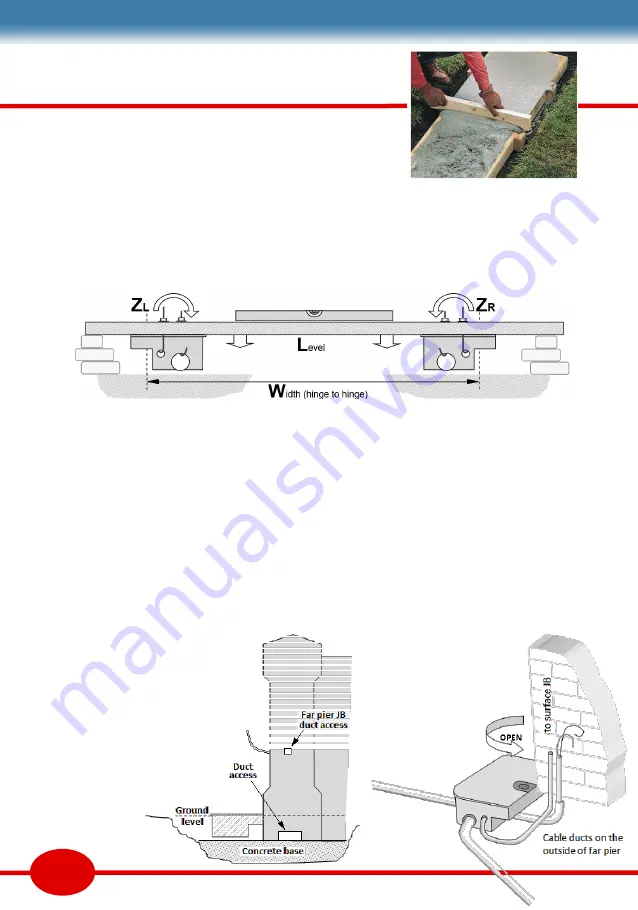

Groundwork & cable ducts

Piers can be constructed hollow, infilled, or with

steel post reinforcement. That is a decision

beyond the scope of this manual.

Two concrete bases are required for the piers,

set at precisely the same level. Level off 170mm

below road level to give casements a solid base,

and space for ducts and drainage to be buried.

More ducts can be laid when the piers are half

height. We recommend 40mm ribbed duct for

cables and 50mm ribbed for drainage. Ducts in

the drawing below are shown terminated at the

base of the pier.

If the pier is to remain hollow, it is tidier to run

cable ducts in the pier. If solid, run the ducts up

the side of the pier (Fig 9). It is a sensible prec-

aution to run a pull cord down any long ducts. If

you have the cable, run the cable as well.

Photobeams are set 500mm

above road level. Add a 20mm

duct in each pier run to an

access hole at on the back face.

The far pier has a JB. The near

pier will have the control panel.

Fig 8

Fig 9a

Fig 9b