10

OWNER’S MANUAL

NEUTON

™

PUMP MODULE

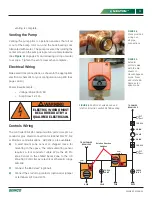

1)

A control panel penetration/bushing will need to

be inserted to accommodate the BAS and/or zone

sensor wiring . Installer should determine optimal

positioning per final installation orientation . The

use of a knockout punch is recommended for

penetration(s) . Install bushing .

NOTE:

Take care to keep the inside of the control

panel free of metal shavings when installing hole .

2)

Mount unit to an appropriate bracing system . The

pump module can be mounted in any position that

allows the pump shaft to be oriented horizontally

while not allowing the terminal box be oriented

in a downward position (See

Figure 3

) . See the

dimensional drawings in

Figures 1D and 2D

for the

dimensions between the four (4) mounting holes

for each configuration . At a minimum, 12” should

be added to the width and 8” to the depth shown

to allow reasonable service access to the pump

and the valves and to allow for a full swing of the

electrical panel door .

3)

Disconnect the o-rings that are attached to the unit

and place on each pipe connection (See

FIgure 4

) .

INSTALLATION & WIRING

RECEIVING & INSPECTION

Upon delivery, confirm that the quantity and model(s) received matches the Bill of Lading . If there is any discrepancy,

immediately notify SEMCO LLC .

Inspect the packages for signs of damage . If damage is suspected, contact SEMCO immediately . If no visible damage

is apparent, the unit should be properly stored until installation .

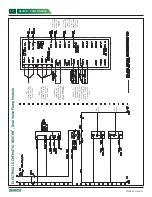

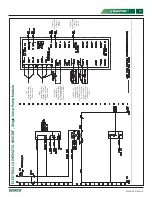

FIGURE 3.

Acceptable (A, B, E) and unacceptable (C, D) mounting orientations . Note that orientation C can be utilized provided that

the pump motor is field rotated to an acceptable position (E) .

A

B

C

D

4)

Make pipe connections . See the dimensional

drawings in

Figures 1A and 2A

for the dimensions

between pipes . All piping connection ports on

NEUTON are 1” female National Pipe Tapered

(NPT) swivel half-union adapters with face gasket

designed to connect to standard 1” male National

Pipe Tapered fittings (NFT) to be provided by the

installing contractor . Tighten the swivel nut by hand

and then gently snug with pliers (1/8 to ¼ turn) for a

leak-free joint . Do not over-tighten or you may cut

the gasket and cause a leak .

5)

WARNING!

Air in the system will damage the pump:

air must be completely eliminated from the pump

module and chilled beam loop using a vent at the

high point . The actuator control valves must be

manually opened to facilitate filling the system (See

Figure 5

) . After the system is filled, the valve should

be returned to automatic operation . Be sure the

knob has “popped” out to the engaged position to

return to automatic mode . See

Figure 6

for position

of valve knob and rotation direction switch after

E