5

OWNER’S MANUAL

NEUTON™

SEQUENCE OF OPERATION

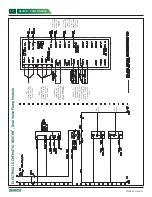

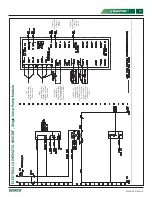

NEUTON™ receives space conditions and setpoints from either a communicating wall mount ZS Pro Zone Sensor or

from the Building Automation System (BAS) . The sequence begins when power is applied to the controller . The BAS

can override the controller operation with a stop command .

The controller modulates the chilled and hot water valves to maintain the desired supply water temperature to the

chilled beams . The water flow is modulated to maintain the desired space temperature setpoint . The controller

accepts occupied and unoccupied setpoints, which may be entered either at the zone sensor, or through the BAS .

Occupied mode is initiated either by a digital input, a call from the BAS, by space CO

2

exceeding the “CO

2

force occupied

mode setpoint,” or by the override button on the thermostat .

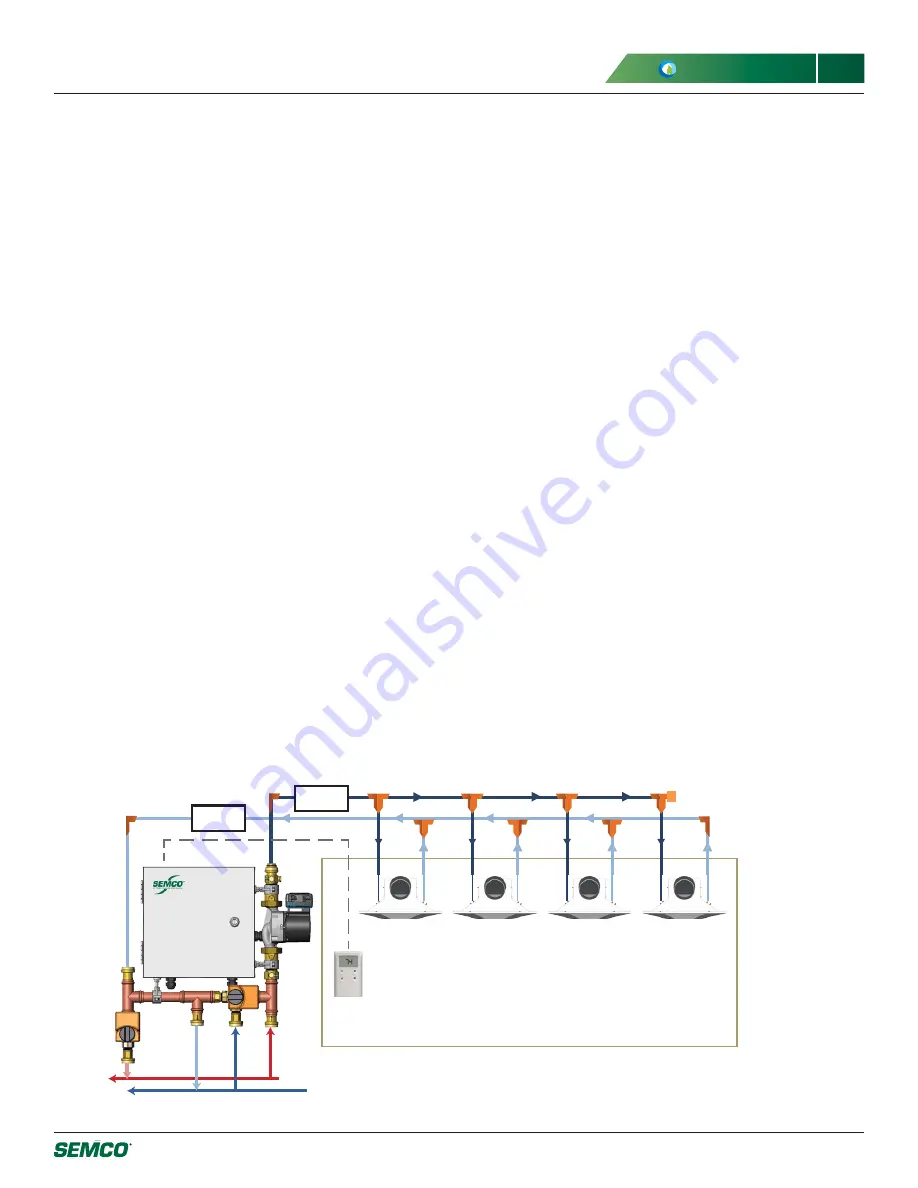

On call for cooling, the chilled water valve modulates to produce the “cooling beginning water temperature” setpoint .

On continued call for cooling, the pump operates at the default mid-range pump speed for a short duration and the

control valves modulate, as required, to achieve the desired beam supply water temperature setpoint .

After a default time delay, if the space cooling setpoint is not achieved or if it is exceeded beyond the deadband

parameters set, the pump speed is modulated between the “Cooling Minimum Pump Output %” and the “Max Pump

Demand” setpoint until space conditions are achieved .

If after reaching maximum pump speed the space cooling setpoint is not achieved, after a time delay, and on continued

call for cooling the water temperature delivered to the beams will be gradually reset until it is equal to the space

dewpoint plus the “water offset above dew-point” setpoint .

On call for heating, the hot water valve modulates to produce the “Heating Beginning Water Temperature” setpoint . On

continued call for heating the water temperature delivered to the beams will be gradually reset until it reaches 100°F .

The pump is running at the “heating minimum pump output %” setpoint while the water temperature is being reset .

When the water temperature reaches 100°F (adj .), and if the space heating setpoint is not reached, the pump demand

will modulate from its heating minimum pump output % setpoint up to the “max pump demand” (if needed) to reach the

space heating setpoint temperature .

58˚F

62˚F

Manual air vent

Beam Zone