19

7.REMOTE CONNECTIONS

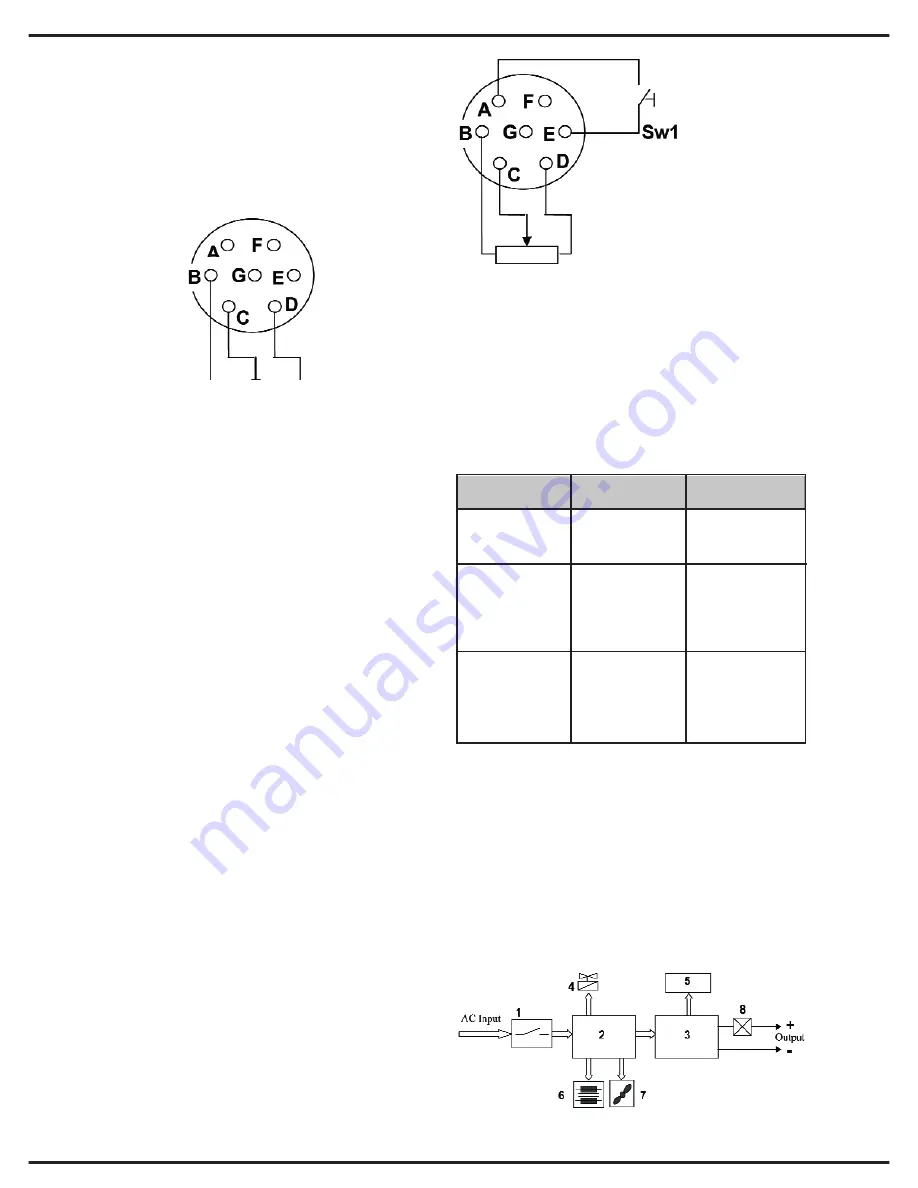

7.1 MMA Welding

Using socket 36 (Fig. 1) the welding

current regualtor coin be used close to

the location where welding will take

place.

Proceed as shown in Figure 9.

The resistance value is of secondary

importance: 2.2kOhm anc 10kOhm

1/2W components are acceptable.

Fimer can supply the accessory

required.

Turning the knob, the welding current

can be set raging from zero to the value

selected using Knob 25 (Fig. 1).

7.2 TIG Welding

Connector 36 (Fig.1) provides contact

between the torch button and the welder via

terminals A and E, as shown in Fig.10.

The connection is automatic when using the

TIG torch.

7.3 TIG WELDING (Pedal-controlled)

Using socket 36 (Fig.1) the welding current

regulator can be used close to the location

where welding will take place.

Using the appropriate accessory, not only

the welding process (start and finish) is

controlled but also the welding current.

When using the original Fimer

accessory, the pedal needs merely to

be connected to socket 36 (Fig.1). The

torch connector is not used.

If a non-original accessory is used, follow

the connection instructions shown in Fig.10.

The resistance value is of secondary

importance: 2.2kOhm and 10kOhm 1/2W

components are acceptable.

8. TROUBLESHOOTING

The most common problems and their

solutions are listed below:

9. BLOCK DIAGRAM

1.

Input Switch

2.

Mains power and control board

3.

Power Module

4.

Solenoid Valve

5.

Display panel

6.

Auxiliary transformer

7.

FAN

8.

Current sensor (installed on block 2)

Sw1 = Pulsante Torcia

P1 = Potenziometro

Fig. 9

Fig. 10

DIFETTO

CAUSA

SOLUZIONE

Arco spento

Cattivo contatto

tra pinza di

massa e pezzo

Stringere la

pinza e controllare

La macchina

cessa improvvi-

samente di fun-

zionare dopo un

uso prolungato.

la macchina è

surriscaldata per

un uso eccessivo

e la protezione

termica è

intervenuta.

Lasciare

raffreddare la

macchina per

almeno 20-30

minuti.

La macchina

cessa di funzio-

nare e sul display

appare la scritta

E.Ln

Tensione di rete

al di sotto del

valore minimo

accettabile.

Verificare se non

si sta utilizzando

un cavo di prolun-

ga troppo lungo

e/o di sezione

inadeguata.

Содержание TT165 AC/DC

Страница 1: ...InstructionManual TT165 AC DC TT205 AC DC TT165 AC DC TT205 AC DC ...

Страница 4: ......

Страница 5: ...TT165 AC DC TT205 AC DC ...

Страница 10: ...X ...

Страница 12: ......

Страница 30: ...20 NOTE ...

Страница 32: ...Cod 910 100 333GB REV00 ...