5

CLEAN ENVIRONMENT

Remove all flammable materials away from

the work environment.

SERIOUS DANGER ! 1

NEVER weld in confined spaces (e.g. in a con-

tainer vehicle, a cistern or a storeroom etc.) where toxic, inflamma-

ble or explosive materials are, or have been, located or stored.

Cisterns, in particular, may still contain toxic, flammable or explosi-

ve gases and vapours years after they have been emptied.

SERIOUS DANGER! 3

NEVER use the Welder to melt frozen water

pipes.

SERIOUS DANGER ! 2

NEVER weld a cistern that contains (or has stored)

toxic, inflammable or explosive materials. They could

still contain toxic, flammable or explosive gases and vapours years

after they have been emptied. If you are obliged to weld a cistern,

ALWAYS passivate it by filling it with sand or a similar inert sub-

stance before starting any work.

WELDING ENVIRONMENT VENTILATION

Ventilate the welding environment carefully. Maintain

sufficient air-flow to avoid toxic or explosive gas accumulation.

Welding processes on certain kinds or combinations of metals can

generate toxic fumes. In the event of this happening, use air-sup-

ply respirators. BEFORE welding, read and understand the wel-

ding alloy safety provisions.

GAS TYPES

These welders use only inert (non-flammable) gases for welding

arc protection. It is important that the appropriate type of gas is

chosen for the type of welding being performed.

UNIDENTIFIED GAS CYLINDERS

NEVER use unidentified gas cylinders.

PRESSURE REGULATOR 1

NEVER connect the cylinder directly to the Welder.

Always use a pressure regulator.

PRESSURE REGULATOR 2

Check the regulator is performing its function properly.

Read the regulator instructions carefully.

PRESSURE REGULATOR 3

Never lubricate any part of the regulator.

PRESSURE REGULATOR 4

All regulators are designed for a specific type of gas.

Check the regulator is appropriate for the protective

gas to be used.

VENTILATION

VENTILATION

Together with the previous instructions, the following pre-

cautions should be strictly observed

PROTECTIVE WELDING GASES

PROTECTIVE WELDING GASES

Together with the previous instructions, the following

precautions should be strictly observed when welding

with protective gases

WALL AND FLOOR PROTECTION

The walls and flooring surrounding the welding

environment must be shielded using non-flammable materials. This

not only reduces the risk of fire but also avoids damage to the wal-

ls and floors during welding processes.

EXTINGUISHER

Place an approved and appropriately-sized fire extinguisher in

the work environment.

Check its working order regularly (carry out scheduled inspections)

and ensure that all parties involved know how to use one.

DAMAGED GAS CYLINDERS

NEVER use damaged or faulty cylinders.

CYLINDER RELOCATION

NEVER lift a gas cylinder by holding the regulator.

GAS CYLINDERS

Do not expose gas cylinders to excessive heat sour-

ces, sparks, hot slag or flames.

GAS HOSE 1

Check the gas hose is not damaged.

GAS HOSE 2

Always keep the gas hose well away from the work

area.

ELECTRIC SHOCK

Together with the previous instructions, the following pre-

cautions should be strictly observed to reduce the risk of

electric shock

ELECTRIC SHOCK INJURY

DO NOT touch a person suffering from electric shock if

he/she is still in contact with the cables. Switch the mains power

source off immediately THEN provide assistance.

CABLE CONTACT

Do not tamper with power cables if the mains power is still

switched on. Do not touch the welding circuitry. Welding cir-

cuitry is usually low voltage, however, as a precaution, do not tou-

ch the welder electrodes.

CABLE AND PLUG PRECAUTIONS

Check the power supply cable, plug and wall-socket regularly.

This is particularly important if the equipment is relocated often.

REPAIRS

Never attempt to repair the Welder yourself. The result would

not only cause warranty cancellation but also high danger risks.

MAINTENANCE PRECAUTIONS

Always check that the electric power supply has been discon-

nected before performing any of the maintenance opera-

tions listed in this manual ( e.g. before replacing any of the fol-

lowing: worn electrodes, welding wires, the wire feeder etc.)

Never point the welding gun or the electrode towards yourself

or others.

Check no power supply cables, telephone cables or other

electrical items (e.g. computer cables, control lines etc.) are

in the vicinity of the Welder.

Check there are no telephones, televisions, computers or other

transmission devices close to the Welder.

ELECTROMAGNETIC COMPATIBILITY

Make sure that people with pace-makers are not in the imme-

diate vicinity of the Welder.

Do not use the Welder in hospitals or medical environments

(including veterinary surgeries). Make especially sure there

is no electrical medical equipment being used close to whe-

re welding is being done.

Should the Welder interfere with other apparatus, take the fol-

lowing precautionary measures:

1.

Check the Welder’s side panels are securely fastened.

2.

Shorten the power supply cables.

Place EMC filters between the Welder and the power source. (Con-

tact Fimer Technical Dept. in this respect )

EMC compatibility : CISPR 11, Group 1, Class A.

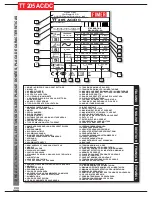

Содержание TT165 AC/DC

Страница 1: ...InstructionManual TT165 AC DC TT205 AC DC TT165 AC DC TT205 AC DC ...

Страница 4: ......

Страница 5: ...TT165 AC DC TT205 AC DC ...

Страница 10: ...X ...

Страница 12: ......

Страница 30: ...20 NOTE ...

Страница 32: ...Cod 910 100 333GB REV00 ...