10

5.

Open the gas cylinder

valve (1). Press the torch button and check

that gas is flowing through correctly.

WARNING:

Cylinders contain high

pressure gas. Handle them with care.

Inappropriate treatment can cause serious

accidents. Do not pile gas cylinders up and

never expose them to excessive heat,

flames or sparks. Do not bang cylinders

against each other. Contact your supplier

for more information regarding the use and

maintenance of gas cylinders.

WARNING:

Never use cylinders that are

damaged or show signs of oil or grease

leakage. Contact your supplier immediately

of any such circumstances.

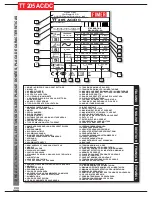

6. WELDING METHODS

The welding mode is selected pressing

button 24 (Fig.1) repeatedly. Check the

correct mode has been selected, i.e. MMA

(LED21 on), normal TIG (LED22 on) or

pulsed TIG (LED23 on).

6.1 MMA Welding (LED 21, Fig 1 ‘on’)

Select this mode pressing button 24

repeatedly until LED21 lights up.

6.1.1 Description

Electric MMA (Metal Manual Arc) and

SMAW (Shielded Metal Arc Welding) are

both manual procedures exploiting the

heat generated by an electric arc that is

produced when covered welding

electrodes make contact with the

workpiece. It is commonly used due to

its versatility. In fact, welding jobs can

be performed anywhere: in a workshop,

in the open, in confined spaces or hard

to reach areas. A wide range of

electrodes are available, suiting all

requirements.

The arc is generated touching the electrode

to the workpiece.

The potentiometer knob (Fig. 1 –25)

regulates the welding current (thicker

workpieces require higher current settings).

6.1.2 MMA WELDING FEATURES

While welding the following features come

into effect:

Arc Force:

Whenever the arc tends to

drop the microprocessor automatically

increases the welding current in order to

maintain and stabilise the arc.

Hot Start:

The arc is generated touching

the electrode to the workpiece. To ensure

the arc is generated efficiently, the

microprocessor increases the welding

current for app. one second, , guaranteeing

fast, safe arc generation.

Antisticking:

Stops the welding current if

the operator makes a mistake causing the

electrode to stick to the workpiece. The

electrode can be removed from its clamp

without causing damaging sparks.

6.1.3 MMA WELDING

Proceed as follows for MMA welding:

1.

Using the button 33 (Fig. 1) set the right

polarity of the welding current. Usually

direct polarity (LED 30 ON).

Always check the suitable polarity indicated

in the electrode manufacurer’s instruction.

2.

According to the type of electrode and the

thickness of the workpiece, set the welding

current using Knob 25 (Fig.1). (The welding

current value is shown on display 13). Figure

4 provides guidelines according to the

diameter of the specific electrode being used.

However, the electrode manufacturer’s

instructions should also be heeded.

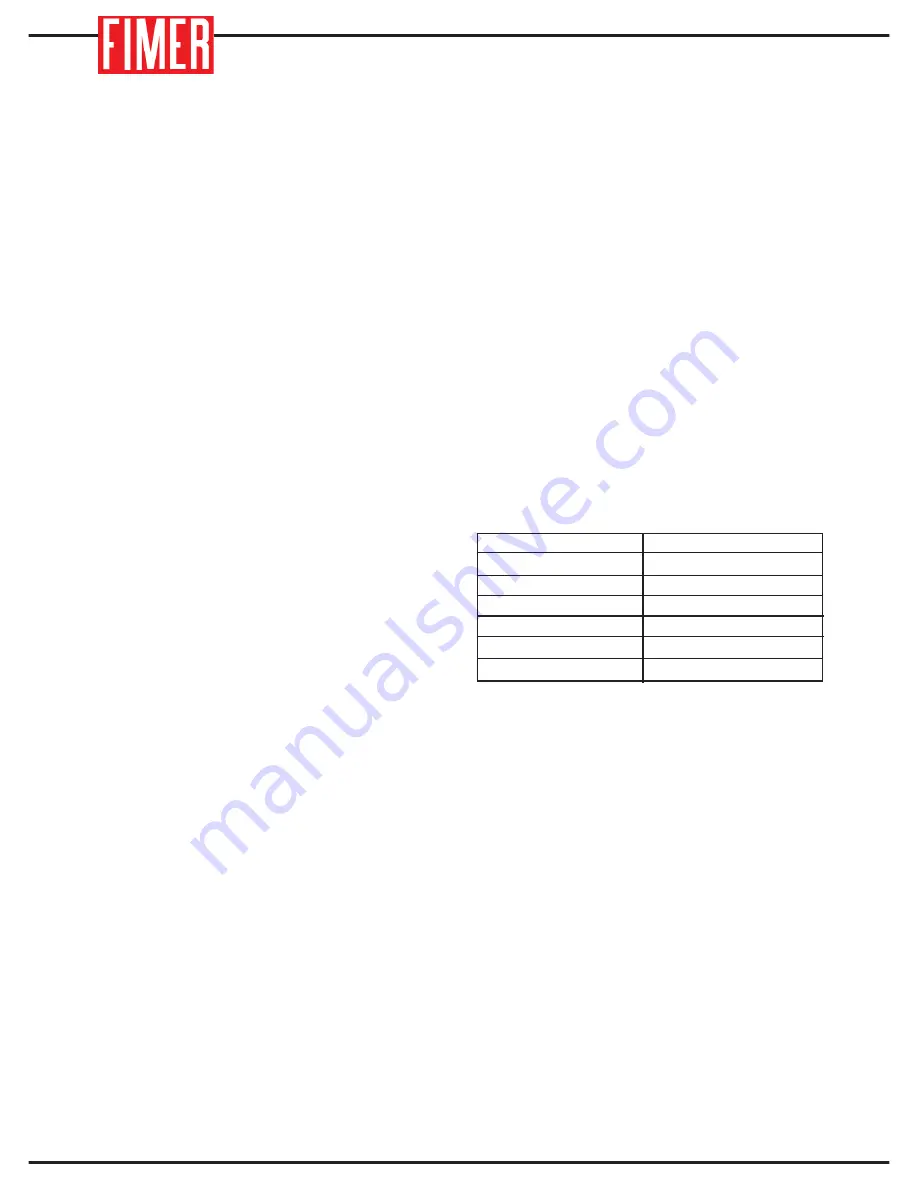

DIAMETRO (mm)

CORRENTE (A)

35-50

40-70

60-100

80-140

120-170

180-250

1.6

2.0

2.5

3.25

4.0

5.0

Fig. 4

Electrode Diameter vs Welding

Current Considerations

Содержание TT165 AC/DC

Страница 1: ...InstructionManual TT165 AC DC TT205 AC DC TT165 AC DC TT205 AC DC ...

Страница 4: ......

Страница 5: ...TT165 AC DC TT205 AC DC ...

Страница 10: ...X ...

Страница 12: ......

Страница 30: ...20 NOTE ...

Страница 32: ...Cod 910 100 333GB REV00 ...