Maintenance

g027801

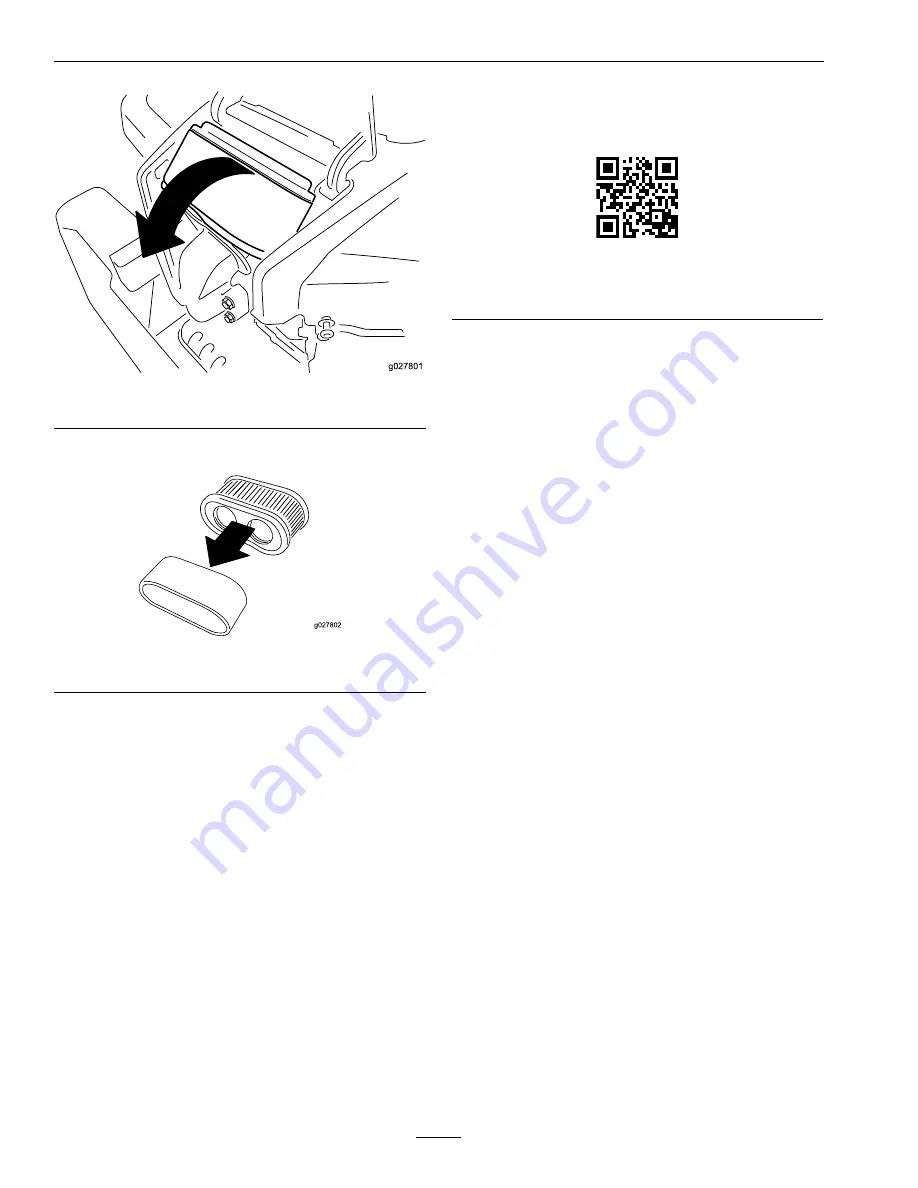

Figure 46

4.

Separate the foam and paper elements.

g027802

Figure 47

Cleaning the Foam and Paper Elements:

Foam Element:

Wash the foam element with water.

Important:

Replace the foam element if it is

torn or worn.

Paper Element:

1.

Lightly tap the element on a flat surface to remove

dust and dirt.

2.

Inspect the element for tears, an oily film, and

damage to the seal.

Important:

Do not clean the paper element

with pressurized air or liquids, such as

solvent, gas, or kerosene. Replace the paper

element if it is damaged or cannot be cleaned

thoroughly.

To learn more about the Exmark twin-cylinder engine

go to https://exmark.com/engines or scan the QR

code.

g028322

Figure 48

Exmark Engine

Checking the Engine Oil Level

Service Interval: Before each use or daily

Important:

Do not overfill the crankcase with oil

and run the engine; engine damage may result.

1.

Park the machine on a level surface, disengage

the blade control switch, stop the engine, engage

parking brake, and remove the key.

2.

Make sure the engine is stopped, level, and is cool

so the oil has had time to drain into the sump.

3.

To keep dirt, grass clippings, etc., out of

the engine, clean the area around the oil fill

cap/dipstick before removing it.

4.

Check the engine oil level.

50

Содержание Radius E Series

Страница 1: ...RADIUS For Serial Nos 408 644 346 Higher Part No 4505 549 Rev A ...

Страница 76: ...Schematics Schematics Electrical Logic Schematic Exmark Engine g036150 76 ...

Страница 80: ...Notes 80 ...

Страница 81: ...Service Record Date Description of Work Done Service Done By 81 ...

Страница 82: ...82 ...