6 TIG WELDING

0460 896 274

- 34 -

© ESAB AB 2013

6

TIG WELDING

Main menu → Process

TIG welding

TIG welding melts the metal of the workpiece, using an arc struck from a

tungsten electrode, which does not melt itself. The weld pool and the electrode

are protected by shielding gas.

Pulsed current

Pulsing is used for improved control of the weld pool and the solidification

process. The pulse frequency is set so slow that the weld pool has time to

solidify at least partially between each pulse. In order to set pulsing, four

parameters are required: pulse current, pulse time, background current and

background time.

6.1

Settings in the weld data setting menu

6.1.1

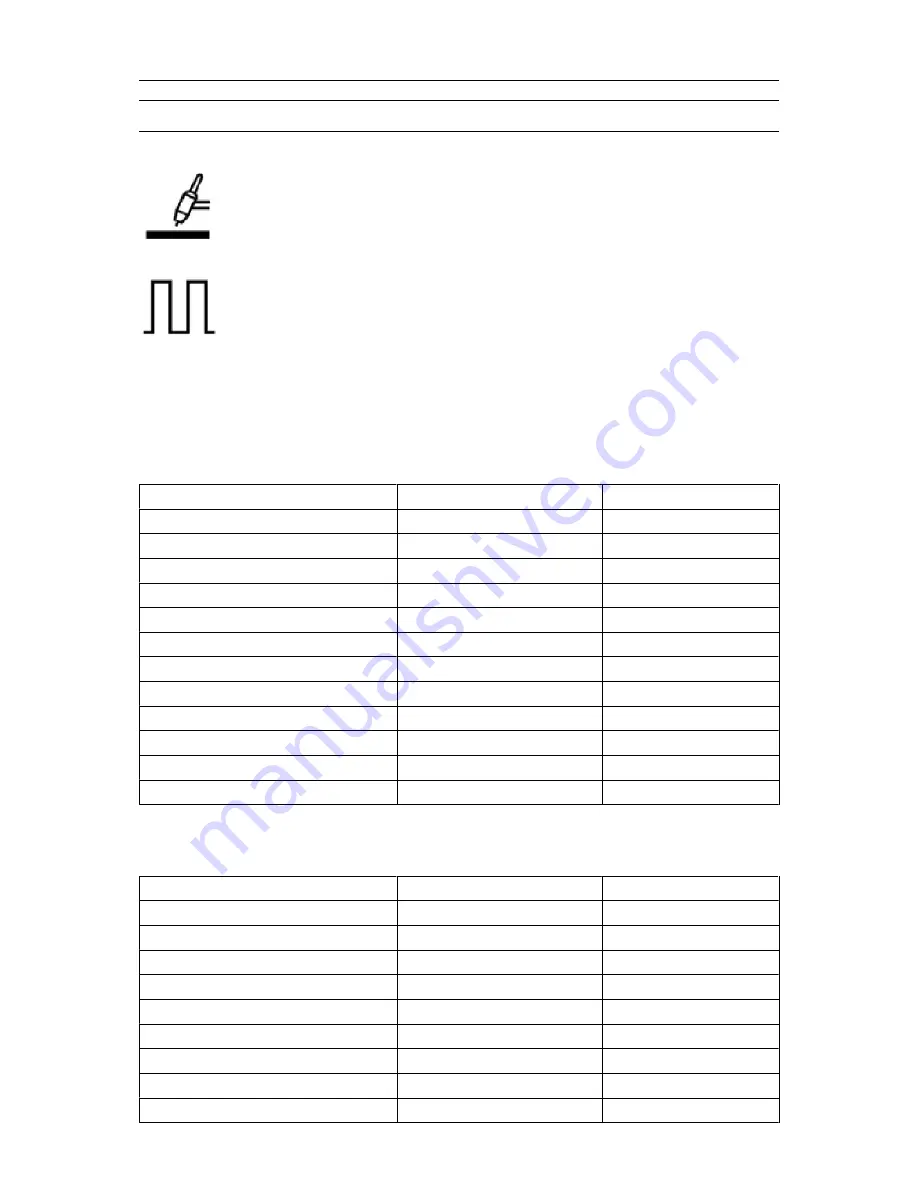

TIG welding without pulsing DC

Settings

Setting range

In steps of

HF/LiftArc™

HF or LiftArc™

-

Live TIG-start*

-

-

2/4 stroke

2 stroke or 4 stroke

-

Current*

4 - 500 A

1 A

Slope up time

0 - 25 s

0.1 s

Slope down time

0 - 25 s

0.1 s

Gas pre-flow

0 - 25 s

0.1 s

Gas post-flow

0 - 25 s

0.1 s

HF automatic start pulse

OFF or ON

-

HF start pulse

4 - 500 A

1 A

Setting limits

0 - 50

1

Measure limits

0 - 50

1

*) Depending on which machine type is being used.

6.1.2

TIG welding with pulsing DC

Settings

Setting range

In steps of

HF/LiftArc™

HF or LiftArc™

-

2/4 stroke

2 stroke or 4 stroke

-

Pulse current*

4 - 500 A

1 A

Background current

4 - 500 A

1 A

Pulse time

0.001 - 5 s

0.001 s

Background time

0.001 - 5 s

0.001 s

Slope up time

0 - 25 s

0.1 s

Slope down time

0 - 25 s

0.1 s

Gas pre-flow

0 - 25 s

0.1 s

Содержание Aristo U82

Страница 1: ...Aristo Instruction manual 0460 896 274 GB 20130902 Valid from program version 1 15A U82 ...

Страница 80: ...MENU STRUCTURE 0460 896 274 80 ESAB AB 2013 MENU STRUCTURE ...

Страница 81: ...MENU STRUCTURE 0460 896 274 81 ESAB AB 2013 ...

Страница 82: ...MENU STRUCTURE 0460 896 274 82 ESAB AB 2013 ...

Страница 83: ...MENU STRUCTURE 0460 896 274 83 ESAB AB 2013 ...

Страница 84: ...MENU STRUCTURE 0460 896 274 84 ESAB AB 2013 ...

Страница 95: ...ACCESSORIES 0460 896 274 95 ESAB AB 2013 ...