SC-F9200 Series

Revision B

DISASSEMBLY & ASSEMBLY

Disassembly and Assembly Procedure

168

SE Group Confidential (Related Staff Only)

4.

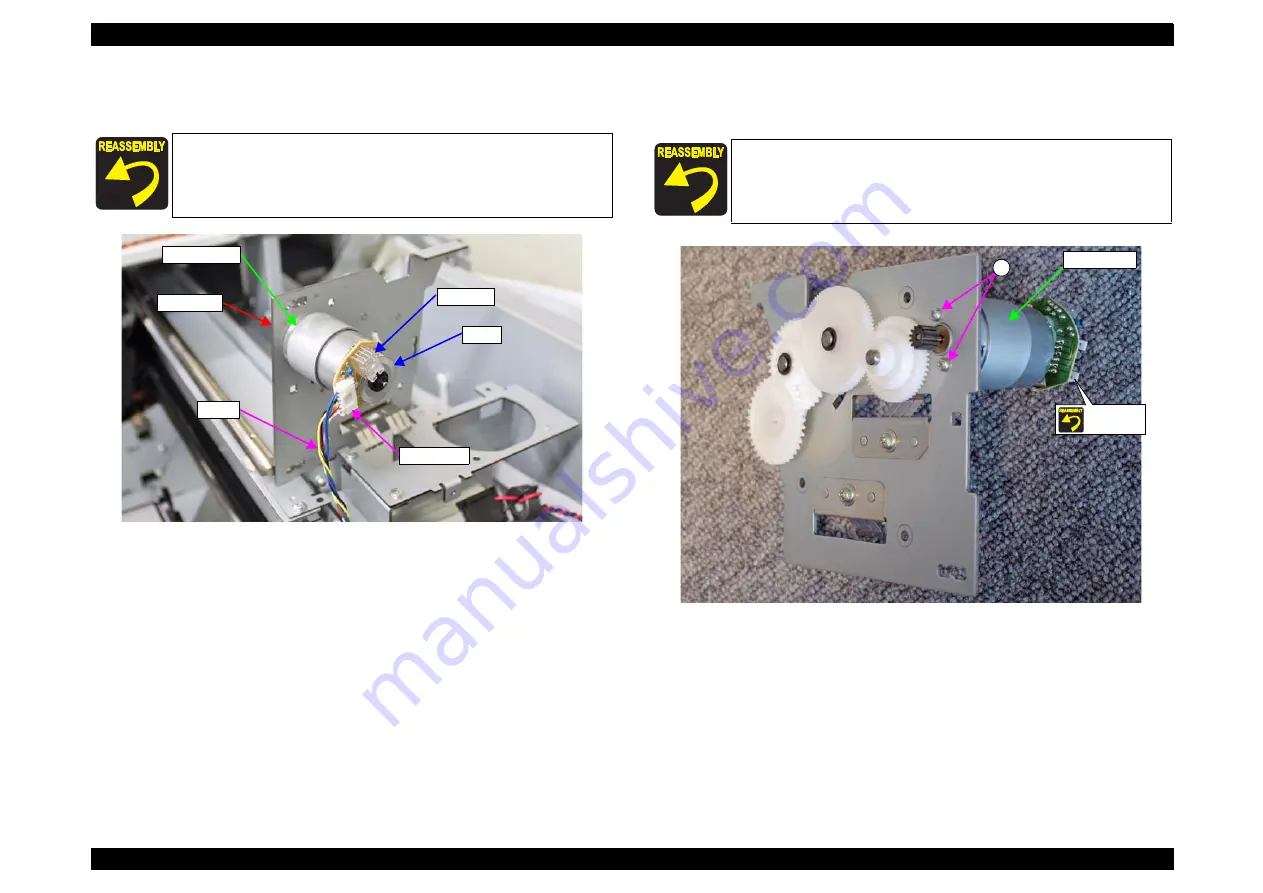

Disconnect the cable from the connector of the APG Motor, and remove the APG

Unit.

Figure 3-108. Removing the APG Unit

5.

Remove the two screws, and remove the APG Motor.

B) Silver M2x4 (Bit No.1): 2 pcs

Figure 3-109. Removing the APG Motor

Be careful not to damage the encoder and scale of the APG Motor.

Scale

APG Motor

APG Unit

Cable

Encoder

Connector

Make sure to install the APG Motor in the correct orientation

checking the connector position.

APG Motor

B

Connector

Содержание SC-F9200 series

Страница 11: ...SE Group Confidential Related Staff Only C H A P T E R 1 PRODUCTDESCRIPTION ...

Страница 37: ...SE Group Confidential Related Staff Only C H A P T E R 2 TROUBLESHOOTING ...

Страница 76: ...SE Group Confidential Related Staff Only C H A P T E R 3 DISASSEMBLY ASSEMBLY ...

Страница 258: ...SE Group Confidential Related Staff Only C H A P T E R 4 ADJUSTMENT ...

Страница 365: ...SE Group Confidential Related Staff Only C H A P T E R 5 MAINTENANCE ...

Страница 389: ...SE Group Confidential Related Staff Only C H A P T E R 6 APPENDIX ...