SMARC T335x Carrier Board Hardware Design Guide, Document Revision 1.2

Copper foils on the outer layers of a PCB (top and bottom layer) often are

thicker due to the via plating process. A common value is one ounce of copper

per square foot. This equals to a thickness of 35

μ

m. The traces of on such

layers have half the electrical resistance, which is 0.5m

for a square shaped

trace. Also consider the electrical resistance of vias. For every ampere of

current, place at least one via.

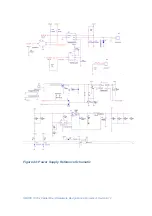

3.7 Reference Schematics

It is possible to reach a suitable power up sequence by cascading the power

good (e.g.

VIN_PWR_BAD#

) output signals of the buck regulators with enable

signal of the next regulator. The

CARRIER_PWR_ON

output features a pull up

resistor on the

T335X

module. An additional pull up resistor can be optionally

placed on the carrier board. This pull up resistor is only needed to prevent

unwanted enabling of the peripheral voltages if the module is not inserted. For

designs in which the module is never removed, this pull up is not required.

The

RESET_IN#

and

RESET_OUT#

can also have additional pull up resistors

on the carrier board for the same reasons.

Содержание SMARC T335 Series

Страница 2: ...SMARC T335x Carrier Board Hardware Design Guide Document Revision 1 2 ...

Страница 118: ...SMARC T335x Carrier Board Hardware Design Guide Document Revision 1 2 Figure 44 Power Supply Reference Schematic ...

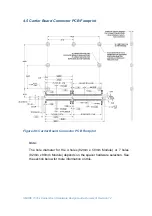

Страница 124: ...SMARC T335x Carrier Board Hardware Design Guide Document Revision 1 2 Figure 46 SMARC T335X Module Mechanical Outline ...