8

produced by this procedure tends to stick to the gas

nozzleholder and nozzle, clean them frequently to avoid

problems (dual arc) that can destroy the nozzle in the

space of a few seconds.

Considering the high level of radiation (infrared and ultra-

violet) emitted during this procedure, we recommend that

the operator and anyone else in the vicinity of the work-

place follow adequate, careful protective measures.

Shut off the machine when you have finished working.

4 CUTTING ERRORS

4.1 INSUFFICIENT PENETRATION

This problem may be caused by:

•

High speed:

Always make sure that the arc fully penetrates the

work-piece, and is never angled forward by more than

10° - 15°. This will avoid incorrect consumption of the

nozzle and burns on the gas nozzle holder.

•

Workpiece too thick (see cutting speed/thickness

diagram).

•

Mass clip not in good electrical contact with the

workpiece.

•

Worn nozzle and electrode.

•

Nozzle hole too large for the current value set on the

knob

Z

.

•

Cutting current too low.

NOTE: When the arc does not penetrate, scraps of molten

metal may damage the nozzle hole.

4.2 THE CUTTING ARC GOES OUT

This problem may be caused by:

•

Worn nozzle, electrode or diffuser.

•

Air pressure too high.

•

Supply voltage too low.

•

Advancement speed too low.

•

Cutting current too high for the thickness of the

workpiece.

4.3 SLANTED CUT

If the cut is slanted, shut off the machine and replace the

nozzle.

Prevent the nozzle from coming into electrical contact

with the workpiece (including via scraps of molten

metal).

This will cause rapid at times instantaneous destruction of

the nozzle hole, leading to very poor quality cutting.

4.4 EXCESSIVE WEAR ON CONSUMER PARTS

This problem may be caused by:

•

gas pressure too low compared to the recommended

value.

•

gas supply circuit damaged.

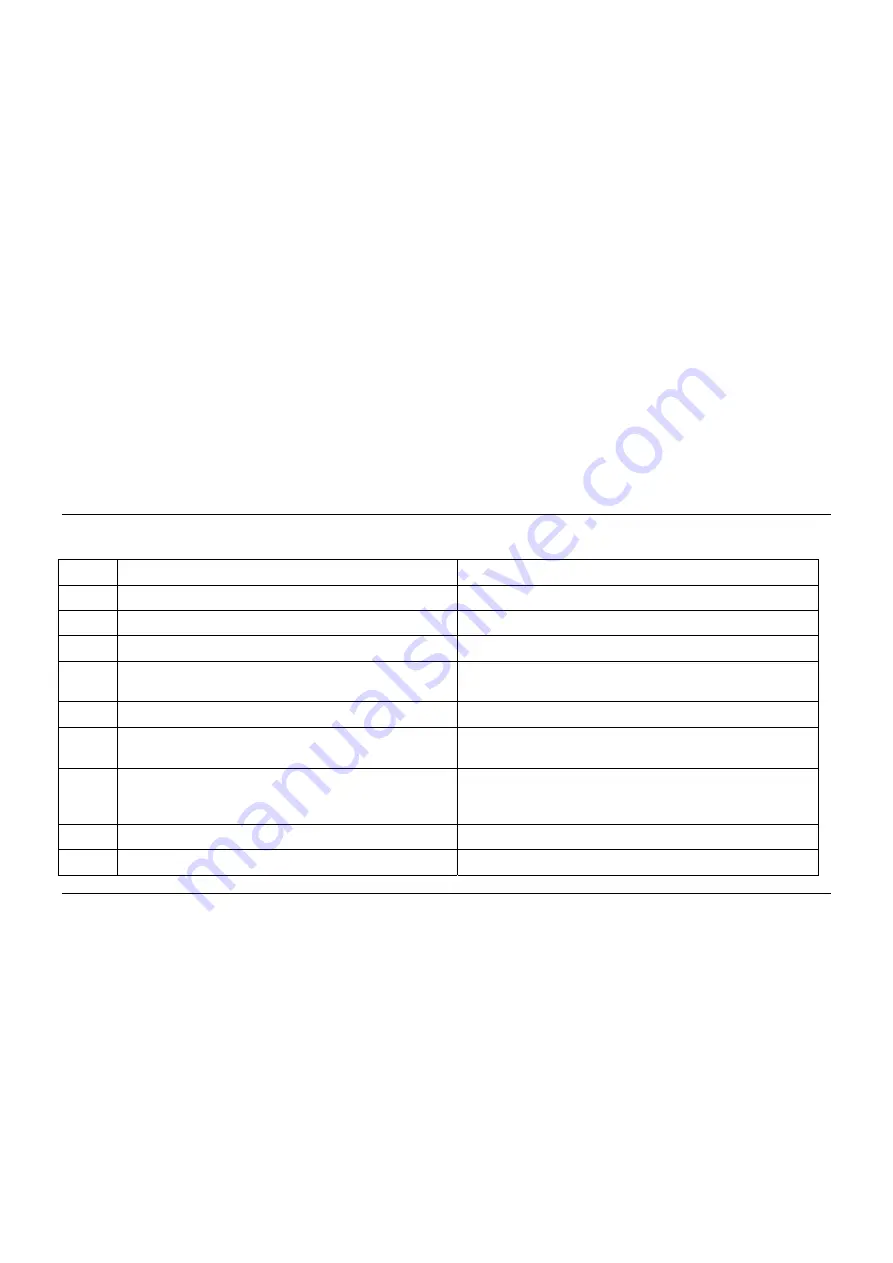

5 ERROR CODES

In the event of a malfunction, the letter

E

may appear on the display

H

, followed by a number with the following meaning:

CODE ERROR

SOLUTION

1 Hardware

lockup

Contact the technical service department.

2 Hardware

lockup.

Contact the technical service department.

12

Transfer reed sensor closed during start-up.

Replace the reed.

13

Hazardous voltage on the torch

Shut the machine off and turn it back on. If the error

recurs, contact the technical service department

51

Torch not recognized.

Check the type of torch. Use only original torches

52

Start button pressed during start-up

Open, the start command, shut the machine off and turn it

back on

53

Start button pressed while resetting the pressure

switch, which shows insufficient pressure, or thermal

reset

Open start command, shut the machine off and turn it back

on

54

Short-circuit between electrode and nozzle

Shut off the machine, check the electrode and the nozzle

55

Electrode finished

Shut off the machine, replace the electrode and the nozzle

6 HELPFUL HINTS

• If the system air contains a considerable amount of

moisture and oil, it is best to use a drying filter to avoid

excessive oxidation and wear of the consumer parts,

damaging the torch and reducing the cutting speed and

quality.

• The impurities in the air may make it difficult to light the

pilot arc. If this occurs, clean the end portion of the

electrode and the interior of the nozzle using very fine-

grained sandpaper.

7 ACCESSORIES

7.1 COOLING UNIT

When using the torch P150W or P150W HF, which requires

water cooling, you must apply the cooling unit.

7.2 INTERFACE CODE 540050

This circuit allows the following functions on the 14-pin

connector

AE

:

A - Start.

B - Arc transferred signal.

C - Signal in proportion to the cutting voltage.

D - Cutting current adjustment.

Содержание PLASMA 167

Страница 2: ...2 2 1 3 4 5 6...