38

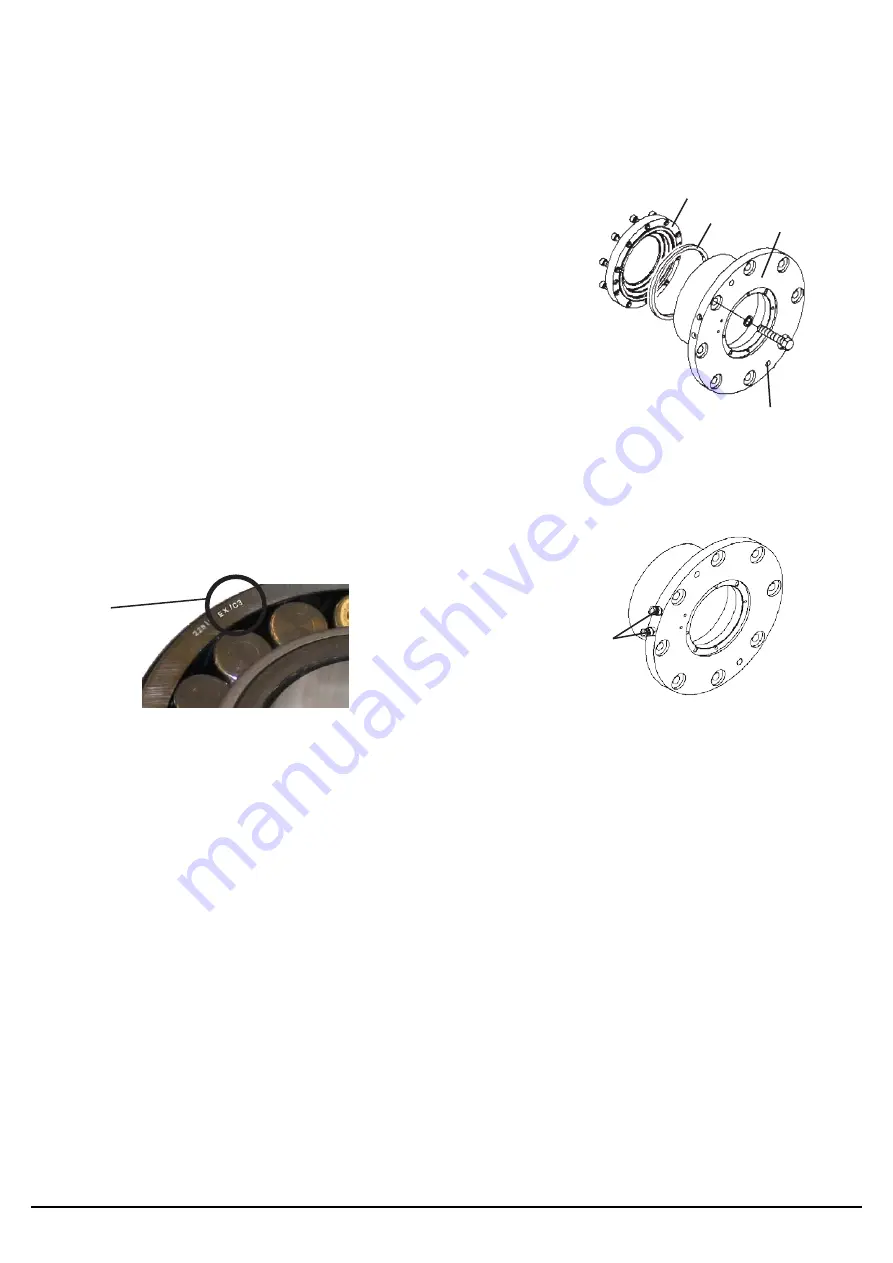

M

N

L

8.

Remove the eight .50” cap screws from the bearing housing

(L) and install two of them into the push off holes to aid in the

removal of the bearing housing. Remove the bearing housing.

NOTE:

When removing the cap screws on the left lower bearing housing

the grease fitting protection guard will also be removed.

9.

Remove the ten socket head cap screws from the inner seal cap

(M) and remove the inner seal cap and spacer ring (N - right

side bearing only).

NOTE:

Two of the cap screws may need to be installed into the push

off holes in the inner seal cap for removal.

10.

Slide or press the bearing out the back of the housing (L).

11.

Inspect the inside of the bearing housing, the withdrawal sleeve

and rotor shaft for defects, such as burrs, worn surfaces or any

surface imperfections. Inspect the rotor shaft seals for damage.

NOTE:

It is recommended to replace rotor shaft seals when replacing

bearings.

PUSH OFF HOLE

C3

LOWER RIGHT HOUSING

IDENTIFICATION

LOWER RIGHT BEARING IDENTIFICATION

NOTICE:

Although the left and right bearings look alike they are different. Be sure to identify and

install the correct bearing during replacement. The right side bearing #600-158 will have a “C3” on

the bearing rim while the left bearing #115439 will not. All other identification marks, letters and

numbers are related to manufacturer and do not have any significance in distinguishing between the

two bearings. Take extra care to install the correct bearing into the correct housing. The right bearing

housing will have the grease and relief ports on the outside flange diameter of the housing while the

left side bearing housing will have the grease and relief ports on the outside flange face of the

bearing housing.

12.

Clean all lower bearing components and rotor shaft, removing all grease and contaminants.

Apply a light coat of machine oil to the inside of the bearing housing and install the new bearing

with the smaller side of the taper in the bearing inner race to the inside of the housing. Check

diagram for correct bearing orientation.

a. Position the bearing as straight as possible with the bearing housing.

b. Position a tube over the bearing, contacting the outer race of the bearing only, and

lightly tap until the bearing is aligned with the housing.

c. Once alignment has been achieved the left side bearing will easily slide into place

while the right side bearing will need a press. Ensure right bearing is fully seated into

the housing.

NOTE:

Apply force to the outer race of the bearing only to prevent damage.

MAINTENANCE & SERVICE

QUALIFIED TECHNICIAN MAINTENANCE

PM-000102-A OCTOBER 2017

37

Содержание Magnum II Series

Страница 2: ......

Страница 56: ...Australian Designed and Manufactured PM 000102 A...