2-20

Service Manual

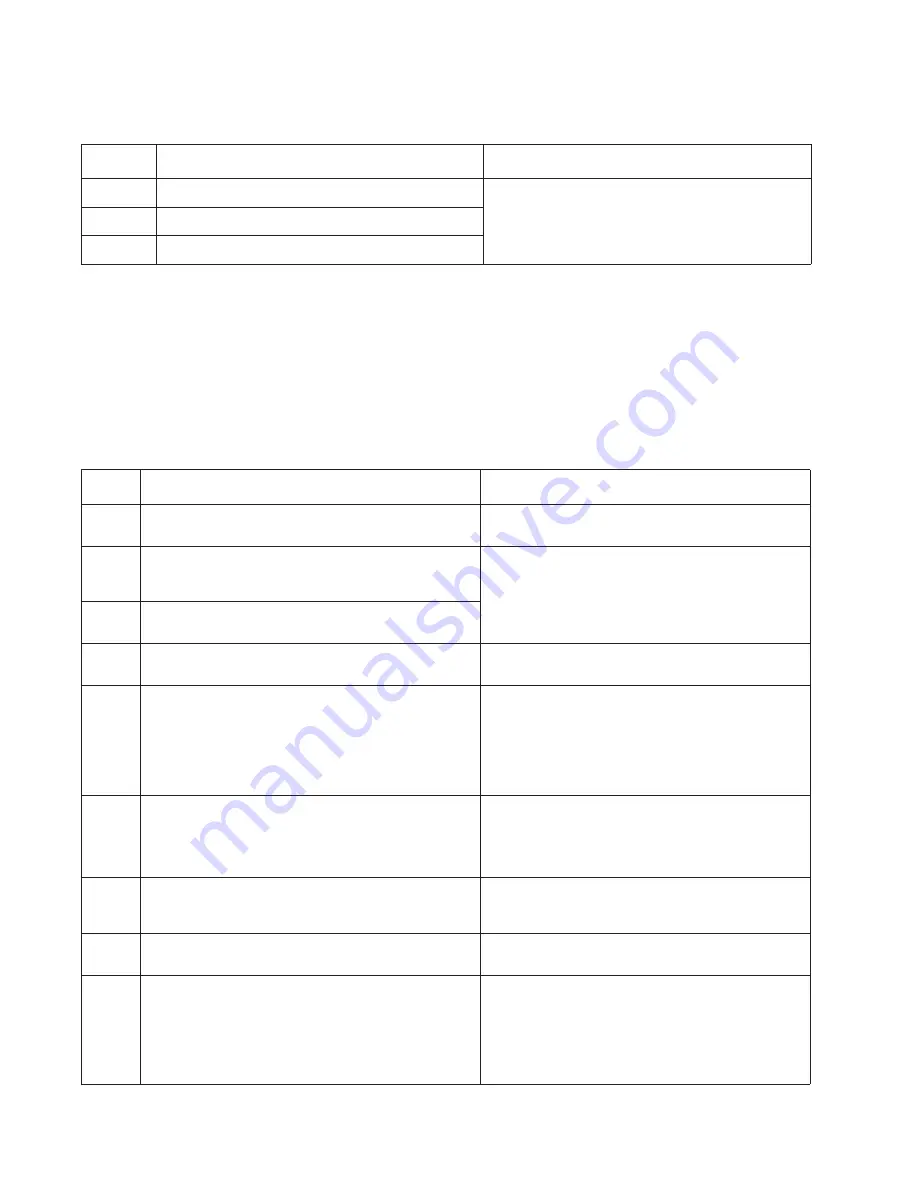

Cartridge error messages

Paper jam error codes (200-series)

Note:

The Event log (See

“EVENT LOG” on page 3-32

) will list any of these errors that have occurred.

Repeating jams or jam messages can be caused by any of the following:

•

Faulty/contaminated pick solenoids or worn cams of the solenoids.

•

Faulty/contaminated flags or springs.

•

Debris in the paper path.

•

Media not of the specified length.

Error

Description

Action

30

Invalid refill

Replace the cartridge.

31

Missing or defective cartridge

32

Unsupported print cartridge

Error

Description

Action

200.00

Paper jam around input sensor.

Remove the PC kit and paper or debris at the input

sensor.

200.01

Classic input jam. The media is too long over the input

sensor. Possible causes include multi-sheet feed, tray

size sensing problem, and media slippage.

First, remove the PC kit and paper or debric at the

input sensor. Then, inspect the flag on the input

sensor. It should rotate freely. Replace the sensor if

necessary. Finally, check the paper size settings in

the printer and the driver.

200.02

The main input sensor never became uncovered from

the sheet ahead.

200.03

The video never started on the page at the input

sensor within two inches after hitting the input sensor

Check the printhead. See

“Printhead service

check” on page 2-54

.

200.04

The media at the input sensor before interrupt

occurred–not enough time elapsed since the printhead

started to expect the printhead mirror motor lock.

Possible causes include bouncy sensor or

exceptionally fast pick– perhaps due to media pre-

staged in the source tray.

Carefully remove the tray and notice if the leading

edge of the media is pointed upward and out of the

tray. If so, then inspect the tray wear strips and

replace if necessary.

Inspect the input sensor flag and replace it if it does

not rotate freely or is too loose.

200.06

Imaged page not expected page (bouncy passthru

sensor)

Remove the toner cartridge/PC kit. At the front,

remove the upper front guide, and inspect the flag on

the manual input sensor. If the flag is loose, then

replace it. See

“Media manual input sensor” on

page 2-52

.

200.08

Media reached the input sensor before the EP was

ready

Inspect the tray for prestaging. Verify the proper

media and inspect the tray wear strips. Replace the

wear strips if necessary.

200.09

Transfer servo never started

Inspect the LVPS/HVPS. See

“Engine board

service check” on page 2-36

.

200.12

Media detected at manual feeder sensor when not

expected. Possible causes include user insert of media

when motor is running or pre-staged media in the tray.

Carefully remove the tray and notice if the leading

edge of the media is pointed upward and out of the

tray. If so, then inspect the tray wear strips and

replace if necessary.

Inspect the input sensor flag and replace it if it does

not rotate freely or is too loose.

Содержание 3333DN

Страница 1: ... 02 Nov 2009 ...

Страница 2: ... ...

Страница 10: ...x Service Manual ...

Страница 15: ...Notices and safety information xv ...

Страница 16: ...xvi Service Manual ...

Страница 28: ...1 8 Service Manual ...

Страница 31: ...General information 1 11 Reduce Enlarge 25 to 400 Copy only ...

Страница 151: ...Diagnostic aids 3 47 3 Remove the jam 4 Close the rear door 5 Close the front door 6 Touch Continue ...

Страница 157: ...Diagnostic aids 3 53 4 Remove the ADF separator roll 5 Remove the jammed media 6 Reinstall the ADF separator roll ...

Страница 160: ...3 56 Service Manual ...

Страница 172: ...4 12 2 Remove the three screws B securing the top of the controller shield B ...

Страница 180: ...4 20 5 Lift the duplex slightly push to the left and tilt to clear the right side of the printer 6 Remove the duplex ...

Страница 182: ...4 22 6 Remove the screw D from the gear E 7 Remove the plastic bushing F ...

Страница 183: ...Repair information 4 23 8 Use a screwdriver to pop the retainer clip G loose from the gear 9 Remove the gear H ...

Страница 186: ...4 26 6 Disconnect the MPF from the lower front cover 7 Disconnect the fuser link A from the front access door A ...

Страница 192: ...4 32 2 Carefully pull the scanner front cover away from the tub assembly ...

Страница 205: ...Repair information 4 45 5 Remove the three screws B from the left door mount B ...

Страница 208: ...4 48 8 Use a screwdriver to pop the inner shaft lock B loose 9 Remove the inner shaft lock C ...

Страница 211: ...Repair information 4 51 5 Remove the e clip B 6 Remove the media feed clutch with cable C ...

Страница 217: ...Repair information 4 57 7 Open the front access door and remove the lower paper guide B ...

Страница 219: ...Repair information 4 59 5 Remove the three screws B from the left side of the printer B ...

Страница 250: ...4 90 12 Disconnect LSU HSYNC extension cable at the connector in the middle of the cable ...

Страница 251: ...Repair information 4 91 13 Remove the three screws A from the left rear frame assembly A A A ...

Страница 252: ...4 92 14 Remove the three screws B from the right rear frame assembly B B B ...

Страница 272: ...4 112 6 Insert the fax card interface cable into the system board connector 7 Lower and lock the scanner assembly ...

Страница 282: ...6 2 Service Manual ...

Страница 284: ...7 2 Service Manual Assembly 1 Covers 3 11 7 13 5 16 9 15 2 10 6 17 4 12 8 14 1 17 18 ...

Страница 286: ...7 4 Service Manual Assembly 2 Imaging 3 11 7 13 5 16 9 15 2 10 6 4 12 8 14 1 ...

Страница 288: ...7 6 Service Manual Assembly 3 Tray assemblies 3 2 1 5 4 ...

Страница 290: ...7 8 Service Manual Assembly 4 Electronics 11 12 7 13 6 14 8 1 2 3 4 5 9 10 17 20 18 19 22 21 16 15 ...

Страница 292: ...7 10 Service Manual Assembly 5 Frame 7 1 2 5 6 7 12 8 See instruction sheet in the FRU 9 10 11 3 4 3 ...

Страница 296: ...7 14 Service Manual ...

Страница 304: ...I 8 Service Manual ...