7 Installation

Installer reference guide

36

ERGA04~08DAV3(A) + EHVH/X04+08S18+23DA

Daikin Altherma – Low temperature split

4P495248-1 – 2017.12

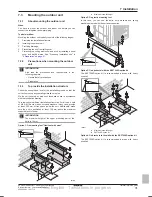

To open/close the stop valve

1

Remove the stop valve cover.

2

Insert a hexagonal wrench (liquid side: 4 mm, gas side: 4 mm)

into the valve stem and turn the valve stem:

Counterclockwise to open.

Clockwise to close.

3

When the stop valve CANNOT be turned any further, stop

turning. The valve is now open/closed.

To handle the stem cap

▪ The stem cap is sealed where indicated with the arrow. Do NOT

damage it.

▪ After handling the stop valve, tighten the stem cap, and check for

refrigerant leaks.

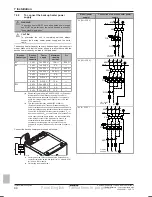

Item

Tightening torque (N∙m)

Stem cap, liquid side

13.5~16.5

Stem cap, gas side

22.5~27.5

To handle the service cap

▪ ALWAYS use a charge hose equipped with a valve depressor pin,

since the service port is a Schrader type valve.

▪ After handling the service port, tighten the service port cap, and

check for refrigerant leaks.

Item

Tightening torque (N∙m)

Service port cap

11.5~13.9

7.5.8

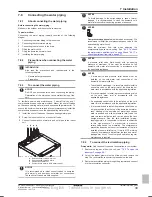

To connect the refrigerant piping to the

outdoor unit

1

Connect the liquid refrigerant connection from the indoor unit to

the liquid stop valve of the outdoor unit.

1×

a

b

c

a

Liquid stop valve

b

Gas stop valve

c

Service port

2

Connect the gas refrigerant connection from the indoor unit to

the gas stop valve of the outdoor unit.

NOTICE

It is recommended that the refrigerant piping between

indoor and outdoor unit is installed in a ducting or the

refrigerant piping is wrapped with finishing tape.

7.5.9

To connect the refrigerant piping to the

indoor unit

1

Connect the liquid stop valve from the outdoor unit to the

refrigerant liquid connection of the indoor unit.

b

a

a

Refrigerant liquid connection

b

Refrigerant gas connection

2

Connect the gas stop valve from the outdoor unit to the

refrigerant gas connection of the indoor unit.

NOTICE

It is recommended that the refrigerant piping between

indoor and outdoor unit is installed in a ducting or the

refrigerant piping is wrapped with finishing tape.

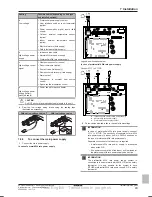

INFORMATION

When the indoor unit is installed in a place with limited

space, an optional pipe bend (EKHVTC) kit can be

installed to facilitate the connection to the refrigerant gas

and liquid connections of the indoor unit. For installation

instructions, see the instruction sheet of the pipe bend kit.

7.6

Checking the refrigerant piping

7.6.1

About checking the refrigerant piping

The outdoor unit's

internal

refrigerant piping has been factory tested

for leaks. You only have to check the outdoor unit's

external

refrigerant piping.

Before checking the refrigerant piping

Make sure the refrigerant piping is connected between the outdoor

unit and the indoor unit.

Typical workflow

Checking the refrigerant piping typically consists of the following

stages:

1

Checking for leaks in the refrigerant piping.

2

Performing vacuum drying to remove all moisture, air or

nitrogen from the refrigerant piping.

Final English - Tanslations in progress