6

s

ectiOn

2 — i

MpOrtant

s

afe

O

peratiOn

p

ractices

Seat belts are attached to the movable portion of the seat

4.

when suspension seats are utilized, and therefore the seat-

mounting base must be secured to its pivot means and the

pivot means latched to the frame of the machine. Seat belts

are attached to the seat or the frame of the machine when

non-suspension (standard) seats are provided, however, if

a suspension kit is added to a seat, the seat belt must be

attached to the movable portion of the seat or suspension

mechanism, the seat-mounting base must be secured to its

pivot means, and the pivot means be latched to the frame

of the machine.

DANGER!

If ROPS and OPDs are folded down or

missing, seat belts shall not be fastened. Worn or

damaged seat belt assemblies must be replaced

prior to operator use.

Brush Guards and canopies can afford additional

5.

protection for the operator. The Brush Guard can deflect

tree limbs, clothes lines, and other obstacles that otherwise

could come in contact with the ROPS and OPDs. Contact

of ROPS and OPDs by items such as tree limbs, clothes

lines, guy wires, and buildings, could create hazardous

conditions whereby the machine could experience a tip-

over or roll-over. The canopy can provide protection for

the operator from some environmental exposure (sunlight,

rain, etc.). Work lights may be available.

The ROPS and seat belt are integral parts of this machine

6.

and should not be tampered with, modified in any manner,

or removed.

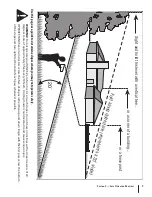

The ROPS extends above and behind the operator position,

7.

and therefore the operator must be aware of potential

contact of the ROPS with items such as trees, buildings,

doorways, clothes lines, utility wires, etc., that could cause

the machine to upset or rollover. Use caution in (or avoid)

areas where the ROPS could come in contact with any

structures, trees, etc.

The ROPS and seat belt add additional mass that elevates

8.

the machine’s Center of Gravity (C.G.) which negatively

affects the machine’s stability and traction. Use extra

caution when operating on slopes.

Inspect the ROPS and seat belt assemblies on a regular

9.

basis for damage and improper operation. Replace all

components that are damaged or are not functioning

properly with authorized replacement parts.

Fail

10.

ure to use the seat belt properly could result in serious

injury or death if an accidental overturn occurs. In order

for the ROPS to be effective, the seat belt must be securely

fastened around the operator at all times when the

operator is on the machine. Contact with the ROPS during

an overturn could cause serious injury or death.

The ROPS will not prevent the machine from upsets or roll

11.

overs.

Only approved attachments should be used on this

12.

machine.

Hydraulic Devices and Systems

Hy

draulic fluid escaping under pressure may have sufficient force

to penetrate skin and to cause serious injury. If foreign fluid is

injected into the skin, it must be surgically removed within a few

hours by a doctor familiar with this form of injury, or gangrene

may result.

WARNING!

Keep body and hands away from

pinholes or nozzles that could eject hydraulic fluid

under high pressure. Use paper or cardboard, not

hands, to search for leaks!

Safely reliev

e all pressure in the system before performing any

work on the system, and make sure that:

The ignition switch is OFF

•

The key is removed

•

The engine spark plug wire(s) removed

•

All connections to the negative terminal of the battery are

•

removed

The park brake is set

•

All by-pass valves, if so equipped, are open

•

Hydrau

•

lic controls are actuated to release pressure on

pumps, cylinders, etc. If “float” positions are available, they

should be used

.

After the above operations are completed, it should be safe to

begin disconnecting the lines or components. It is still a good

idea to cover the connection with a cloth shield and then gently

loosen connections.

WARNING!

Make sure all hydraulic fluid

connections are tight and all hydraulic hoses and

lines are in good condition before applying pressure

to the system.

Service

Related to Fuel

DANGER!

Never have the mower near an open

flame or spark, or allow smoking when refueling the

system. Always handle LPG cylinders with care.

LPG is a safe but highly flammable fuel.

Always handle LPG with care. LPG is a safe but highly

1.

flammable fuel. Please respect it.

LPG causes skin burns on contact. Aviod contact and wear

2.

appropriate clothing, gloves and eyewear.

If you smell or see gas, or hear the hiss of escaping gas,

3.

immediately get away from the cylinder and contact your

local fire department.

Do not smoke or permit others to smoke while handling

4.

LPG.

Always close the valves on the cylinders when not in use.

5.

Use only cylinders that meet code #49 of the federal

6.

regulation #173.34.

Use LPG classified HD-5 by national Gas Processors

7.

Association (nGPA).

never attempt to remove an LPG cylinder while the mower

8.

is running.

Содержание Tank S S7237

Страница 45: ...Notes 12 45 ...