30

s

ectiOn

6— M

aintenance

& a

djustMents

engine and re-check hydraulic oil. If oil appears foamy or

contains excessive air bubbles, DO nOT OPERATE UnIT.

Contact service technician.

Contaminants or foreign matter in the oil will also damage the

pumps . To prevent this:

Use a filter that captures particles as small as 25 microns or

•

25 millionths of a meter in diameter.

Be very careful when you remove or repair a component in

•

the hydraulic system. Thoroughly clean off any component

before you work on it.

Plug the ends of any hose or line you remove with a rubber

•

or plastic plug.

Use plastic caps to seal off the ends of hydraulic fittings.

•

Place any component you remove in a clean plastic bag so

•

it can’t pick up dust or dirt.

Clean your hands frequently when working on the

•

hydraulic components.

NOTE:

The pumps are not owner-repairable. If a pump fails,

contact your Service Center. Do not disassemble the pump.

Hydraulic System

Hoses

Check the hoses from the hydraulic oil tank to the oil filter to

the hydraulic lines daily for leaks or abrasion and replace any

damaged hoses. Make certain there are no kinks or twists in any

hose. Look for a flattened condition or any leaks and repair or

replace as necessary. A flattened or leaking suction hose will

permit cavitation to develop which can destroy the pumps in a

short time.

General Battery Information

WARNING!

— Should battery acid accidentally splatter into

the eyes or onto the skin, rinse the affected area

immediately with clean cold water. If there is any

further discomfort, seek prompt medical attention.

— If acid spills on clothing, first dilute it with clean

water, then neutralize with a solution of ammonia/

water or baking soda/water.

— NEVER connect (or disconnect) battery charger

clips to the battery while the charger is turned on, as

it can cause sparks.

— Keep all sources of ignition (cigarettes, matches,

lighters) away from the battery. The gas generated

during charging can be combustible.

— As a further precaution, only charge the battery

in a well ventilated area.

— Always shield eyes and protect skin and clothing

when working near batteries.

— Batteries contain sulfuric acid and may emit

explosive gases. Use extreme caution when

handling batteries. Keep batteries out of the reach

of children.

Battery Maintenance

The battery is filled with battery acid and then sealed at

•

the factory. However, every 50 operating hours remove the

fill caps and check the level of the liquid electrolyte in the

battery. If the level in any of the six cells has dropped below

the bottom of the split ring inside the fill hole, refill the cell

with distilled water.

Spray the terminals and exposed wire with a battery

•

terminal sealer, or coat the terminals with a thin coat of

grease or petroleum jelly, to protect against corrosion.

Always keep the battery cables and terminals clean and

•

free of corrosion.

Avoid tipping. Even a sealed battery will leak electrolyte

•

when tipped.

Tire Maintenance

Check the tire air pressure before each use. Inflation pressure

of the rear tires is important for stability while the mower is in

operation. If the tire diameter is not equal between the two tires,

the mower will pull to one side. Keep the tires inflated to the

recommended pressures. Improper inflation will shorten the tire

service life. See the tire side wall for proper inflation pressures.

Observe the following guidelines:

Do not inflate a tire above the maximum pressure shown

•

on the sidewall of the tire.

Do not reinflate a tire that has been run flat or seriously

•

under inflated. Have a qualified tire mechanic inspect and

service the tire.

Balance inflation pressure between the rear tires to heLPG

•

maintain straight travel (see tire side wall for proper

inflation pressure).

Keep the valve caps tightened to prevent air pressure loss.

•

Inflation Pressure

Traction Tires — 20 psi max; 10-12 psi recommended

Front Wheel — 25 psi max; 20-25 psi recommended

Cutting Deck Ball Wheels — Solid Polyurethane

Leaking Tires

When a flat tire occurs, repair or replace immediately. The normal

procedure is to remove the wheel and replace it. If a tire is

getting soft, park the mower on the nearest level, paved area.

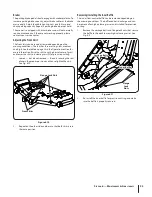

Rear Tire

1.

Put blocks on each side of the opposite traction

a.

wheel and jack up the tire that leaks about an inch

off the ground.

Loosen and remove the lug nuts and remove the

b.

wheel.

Mount a wheel and tire, replace the lug nuts, and

c.

using a torque wrench, tighten them to 60 ± 10

ft-lbs.

Содержание Tank S S7237

Страница 45: ...Notes 12 45 ...