36

MYDENS 60

COSMOGAS

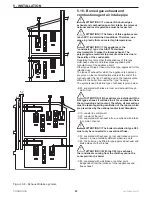

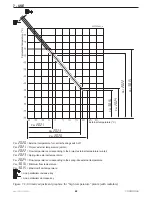

Figure 6.9 - Combustion agent air pressure point

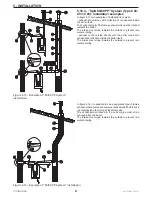

Figure 6.11 - Controlling combustion agent air

pressure

6.7 - Controlling the combustion

agent air pressure

As the boiler has an air/gas ratio fixed in the factory, the gas

pressure at the burner is controlled indirectly by measuring

the pressure of the combustion agent air inside the boiler and

must correspond to that stated in the table in chapter 9, under

“Combustion agent air pressure”.

Proceed as follows for the check (refer to the Figures from

6.9 to 6.12):

1.- use a differential manometer with precision of at least 0.1

mbar (1 mmH2O);

2.- close the gas cock;

3.- open the boiler casing following chapter 8.2;

4.- remove the caps “A” (see figure 6.9);

5.- take the flexible hose “D”, which is found inside the

appliance and remove the cap “B” (see figure 6.9);

6.- insert the pipe “D” inside the hole indicated by the arrow

in figure 6.9;

7.- loosen the pressure point “H” in figure 6.10;

8.- take a silicone pipe with external diameter of 10 mm and

internal diameter of 7mm (detail “E” in figure 6.10) and

introduce it into pressure point “H”;

9.- insert pipe “E” into the hose as indicated in figure 6.11;

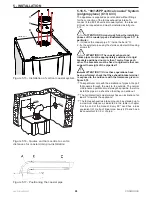

10.- connect the manometer to the two pipes “E” and “F” as

illustrated in figure 6.12, making sure to connect the pipe “E”

to the negative pressure point and tube “F” to the positive

pressure point;

11.-

close the casing “B” in figure 8.1. It is indispensable

to have a reliable measurement;

12.- switch the boiler on;

13.- press the

and RESET keys simultaneously

for more than 5 seconds to enter the “installer” menu,

confirmed by the appearance of the icon

on the

display.

14.- using the

and

keys, access the

parameter

2010

;

15.- press the RESET key to enter the parameter and use the

and

keys, to modify the value to

FAn

;

16.- press the RESET key to confirm the modification. Now

the fan will operate at maximum speed for 10 minutes.

17.- compare the pressure value read on the manometer with

that given in the table in chapter 9, “Combustion agent air

pressure”. If the pressure is at a lower value, check that

there are no obstructions in the combustion agent air/fumes

exhaust or that the air intake/fumes exhaust system is not

longer than envisioned in chapter 9 under “Max. length of

fumes pipe”;

18.- once the control has ended, press the RESET key again

to enter parameter

2010

and via the

and

keys, change the value to

OFF

;

19.- press the RESET key to confirm the modification;

20.- hold the RESET key down for 5 seconds to exit the

“installer” menu.

At the end of the control, remove the tube “E”, close the

holes in the lower frame with the caps “A”, close the pipe

“D” using cap “B” and close the pressure point “H” again as

in figures 6.9 and 6.10.

6 - OPERATING

D

A

C

B

020002.01.019

D

C

E

F

020002.01.020

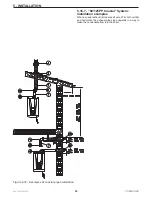

Figure 6.10 - Combustion agent air pressure point

H

E

020002.01.022

Содержание MYDENS 60

Страница 63: ...63 MYDENS 60 COSMOGAS 8 MAINTENANCE ...

Страница 71: ......

Страница 72: ...COSMOGAS s r l Via L da Vinci 16 47014 MELDOLA FC ITALY info cosmogas com www cosmogas com ...