16

MYDENS 60

COSMOGAS

5 - INSTALLATION

the winter the leaks on radiator valves are often not visible

because they are dried by the heat produced by the radiator

or boiler). These micro leaks however allow air to enter the

plant. The main points that can give rise to micro leaks are in

the joints and, in particular, from the intake side of the pump

(air vent valves, o-ring seals, loading valves). In these cases,

the plant must be protected with a suitable corrosion inhibitor

in order to prevent damage.

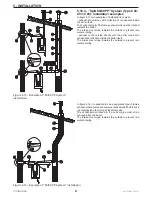

5.6.2 - For correct plant operation it is

necessary to ascertain that:

1) there are no leaks in the plant or the most evident ones

have been eliminated;

2) if an automatic filling system is present, a litre meter must

be installed on order to know the precise size of any leaks;

3) the plant must be filled and topped up with softened water

in order to reduce the total hardness. The water must also be

conditioned in order to maintain the pH within the threshold

envisioned in order to prevent corrosion phenomena;

4) both in new plants and replacements, there must be efficient

systems that eliminate air and impurities: filters, separators of

micro impurities and separators of micro air bubbles;

5) do not drain plant water during routine maintenance, even

if it appears to be an apparently insignificant amount: for

example to clean filters, supply the plant with the relative

cut-off valves upstream and downstream from the filter itself;

6) always analyse the plant water before opening the

communication between the new generator and plant, to

establish whether the chemical and physical features of the

water indicate the necessity to empty the plant completely, the

use of the water already present in the plant or the chemical

washing of the plant, using mains water with the addition of

a detergent, when it is suspected that the plant may be dirty

or particularly clogged and the successive new loading of

treated water.

If the analysis of a sample of water that will be used to load

the plant shows the following factors:

- 9.6 < pH < 10.5 (if the plant is in contact with aluminium, the

pH must be lower than 8.5)

- Ca++ + Mg++ : <0.5°f

- OH + 1/2 C03 : from 5 to 15°f

- P205: from 10 to 30 mg/l

- Na 2S03: from 20 to 50 mg/l loading can be continued. A

inhibitor must be used if the features are different.

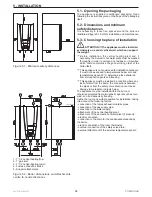

5.6 - Water supply

Have the water network connection pressure checked. If

necessary, have a suitable pressure reducer installed.

ATTENTION !!! The central heating plant (and

therefore the heat module) must be connected to the

water mains with the interposition of a device that

prevents backflow of drinking water towards the plant,

as requested by the current Anti-pollution Safety

Standards.

5.6.1 - Recommendations of the features

of the water inside the plant

Filling the central heating plant is an extremely delicate

operation, not to be underestimated, regarding replacement

of the heat generator or new installations. In certain cases, the

incorrect assessment of the plant water features can lead to

damage of the plant and heat module. A plant is almost never

sealed perfectly; sometimes water leaks as well as the entry of

oxygen can occur. Both of these phenomena are dangerous.

The main parameters that can negatively affect the lifespan

of the plant are:

- The simultaneous presence of different metals (copper,

brass, steel and aluminium) which, in aqueous environments,

give rise to galvanic corrosion.

- The presence of free oxygen, due to the infiltrations of air

that occur in proximity of fittings and gaskets, constitutes a

typical corrosive agent, particularly active at temperatures

between 50 and 70° C.

- The loss of water, which leads to frequent top-ups, can act in

a corrosive manner and as a deposit, depending on the type

of water available to top-up the same.

In all cases, the size of the leaks (and relative top-ups) must

be kept under control, especially when an automatic filling

system is installed. In this case, the installation of a meter is

highly recommended, which indicates the amount of water

reintegrated.

Natural impurities or added in the water. Many drinking waters

can contain high concentrations of chlorides and sulphates,

which can increase the speed of corrosion on metal surfaces.

Other undesired components could have been introduced into

the plant before or during installation (construction materials,

metal shavings, sawdust, grease, deposits and dirt in general).

Welding residues can also cause corrosion, both in the case of

new plants and in the case of modifications or repairs. In the

old plants designed to operate with radiators, characterised

by a very large piping diameter, the water content in the

plant is noteworthy and promotes the formation of sludge

and deposits.

Sludge and Deposits The presence of black deposits

(magnetite) indicate that corrosion is limited; however, the

high specific weight of this oxide can cause difficult to remove

clogging, especially in the hottest areas. The deposits are

due to the hardness of the water, i.e. the presence of calcium

and magnesium salts. The calcium goes to the hottest areas

of the plant in the form of carbonate. The magnetite often

contributes to strengthening the deposit. The iron oxide (the

water is a reddish colour) is a sign of corrosion by oxygen.

Frequent leaks In the event of frequent leaks, hydrogen and/

or air accumulate on the top part of the heat exchanger and

the radiators, preventing complete heat exchange.

When the electrolytic corrosion process starts, the level of the

water in the plant drops and gases accumulate on the top part

of the heat exchanger and on the radiators. The presence of

air is caused by the fact that the plant may not be perfectly

sealed. A slow drop in plant pressure due to a leak is often

difficult to find, especially when the flaw is very small (in

Содержание MYDENS 60

Страница 63: ...63 MYDENS 60 COSMOGAS 8 MAINTENANCE ...

Страница 71: ......

Страница 72: ...COSMOGAS s r l Via L da Vinci 16 47014 MELDOLA FC ITALY info cosmogas com www cosmogas com ...