17

MYDENS 60

COSMOGAS

5 - INSTALLATION

5.6.3 Treatment of the water in the thermal

plants for civil use

The water in the heating plants for civil use must always be

treated on replacement of the generator and in the event of

a new plant.

On the basis of the features of the raw water, in the design

phase all treatment plants and the chemical conditioners

necessary to obtain water with the following features, must

be envisioned:

- Aspect: possibly clear;

- pH: over 7 (with radiators with aluminium elements of light

alloys, the pH must be lower than 8.5);

- Conditioners: present within the concentrations prescribed

by the supplier.

If the features of the of the water are not known, the probability

of the following typical drawbacks occurring is high:

1. LIME SCALE FOULING

1 °fr = 10mg/kg CaCO

3

30° fr = 300 mg/kg CaCO

3

In a plant that contains 1000 litres of water at 30°f, the content

of CaC03 is equal to 300 gr, which if not treated suitably,

will deposit on the surface of the heat exchanger as this

is the hottest point of the plant. This creates concentrated

temperature increases with consequent breakage of the heat

exchanger.

2. CORROSION

Corrosion is normally promoted by the presence of oxygen,

by the contact between different metals or the presence of

chlorides.

3. DEPOSITS

They are insoluble organic and inorganic substances:

SLUDGE, WORKING RESIDUES.

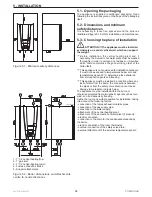

5.7 - Draining the heating circuit

To avoid continuous renewal of water and consequent input

of oxygen and limestone, it is recommended to limit every

heating circuit drainage as much as possible.

5.8 - Expansion Tank

ATTENTION !!! Provide the plant with an

appropriately dimensioned expansion tank, as

envisioned by the national and local Installation

Standards.

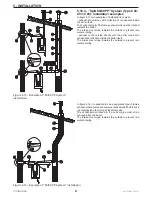

5.9 - Low temperature

plants (or on the floor)

ATTENTION !!! The plant downstream from

the appliance must be made with materials that

resist temperatures up to 97°C and pressure of 3 bar.

Differently (e.g. plastic piping) the plant must be fitted

with the relevant protection and safety devices.

ATTENTION !!! when installing the boiler in

a low temperature plant, it is indispensable to set

parameter

3015

at the value of 45°C and parameter

3016

at the value of 20°C (see chapter 11).

With this setting, the boiler will adjust the flow to a

temperature between 20°C and 45°C. No adjustment from

the command panel (also via climatic adjustment),can

supply water at a temperature over 45°C.

ATTENTION !!! If the boiler is installed in a floor

plant made with plastic piping, all of the precautions

must be taken against corrosion due to oxygen in the

water:

make sure that the plant is made with plastic pipes with

permeability to oxygen not exceeding 0.1 g/m3 at 40°C.

Whenever the pipe should not meet these features, the

radiant panel circuit from the boiler must be isolated via

a plate heat exchanger, suitable to resist the corrosion

generated by the oxygen dissolved in the water.

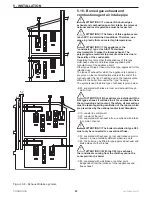

5.10 - Gas

ATTENTION !!! It is prohibited to power the

appliance with gases different to that envisioned.

ATTENTION !!! Check that the gas and supply

pressure are those for which the boiler has been

adjusted.

Two situations are possible:

A - the gas and supply pressure correspond to the

adjustment of the boiler. In this case, it can be

connected;

B - the gas and supply pressure do not correspond to the

adjustment of the boiler. In this case, the boiler must

be converted to the type of gas and supply pressure

corresponding to the supply available.

The boiler is provided with the relevant gas conversion kit.

Before installation it is advised to clean the inside of the

gas supply pipe thoroughly;

A cut-off cock must always be installed on the gas

supply pipe;

To prevent damage to the appliance gas control unit,

perform the leak test at a pressure not exceeding 50

mbar;

If the gas plant must be inspected at pressures over

50 mbar, operate on the cock positioned immediately

upstream from the boiler, to isolate the same from the

plant.

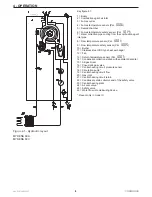

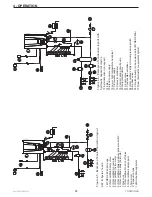

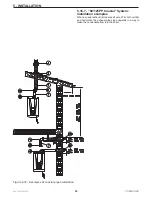

Figure 5.2 verifies the positioning of the appliance gas fitting.

The sections of the pipes making up the gas supply plant

must always guarantee a gas supply sufficient to cover the

maximum requested.

Содержание MYDENS 60

Страница 63: ...63 MYDENS 60 COSMOGAS 8 MAINTENANCE ...

Страница 71: ......

Страница 72: ...COSMOGAS s r l Via L da Vinci 16 47014 MELDOLA FC ITALY info cosmogas com www cosmogas com ...