6

TECHNICAL DESCRIPTION

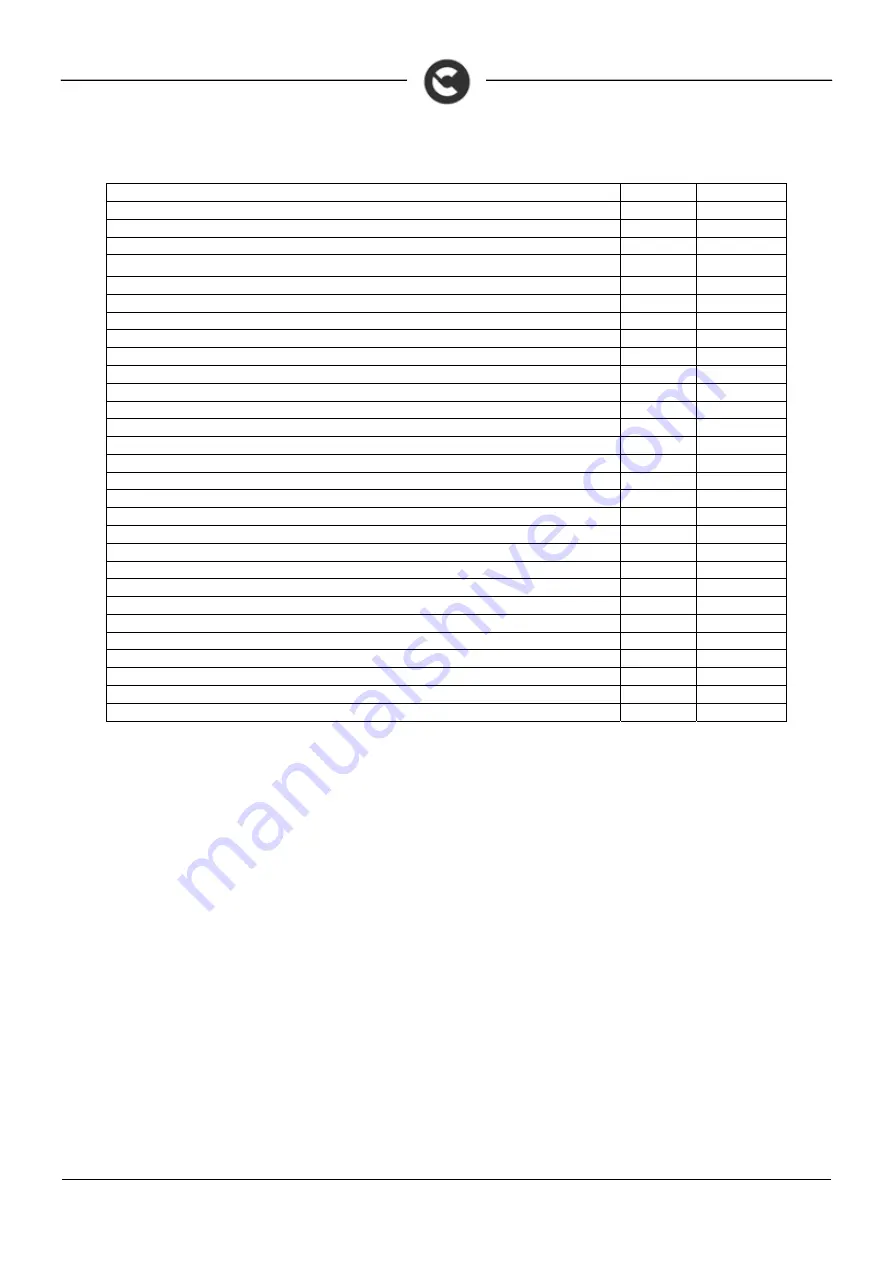

UM ULTRA120

B

Working width

mm 1205

Squeegee width

mm 1265

Work capacity, up to

m

2

/h 9600

Disk brush

No. /

mm

2 / 610

Brush rotations

rpm 115

Brush motor

V/W 36/2000

Maximum pressure on the brushes

kg

95

Traction motor

V/W 36/2000

Traction wheel

mm

310 x 100

Maximum forward speed

km/h

8

Maximum gradient with full load

%

10%

Suction motor

No./(V/W) 2/(36/670)

Suction vacuum

mbar 190

Rear elastic wheels

mm

370 x 140

Solution tank

l 280

Recovery tank

l 285

Detergent tank (CDS version only)

l 15

Steering diameter

mm 3420

Machine length

mm 2030

Machine height

mm 1560

Machine width (without squeegee)

mm 1280

Battery compartment (l x L x h)

mm

880x600x450

Rated battery voltage

V 36

Battery weight (max)

kg 510

Machine weight (empty and without batteries)

kg

760

Gross weight in running order (m bat water + operator)

kg 1630

Noise level (in compliance with IEC 704/1)

dB (A)

-

Hand vibration level

m/s

2

-

Body vibration level

m/s

2

-