13

MACHINE PREPARATION

1. HANDLING THE PACKAGED MACHINE

The machine is contained in specific packaging with a pallet for the handling with fork trucks. The

packages cannot be placed on top of each other.

The total mass of the machine with packaging is 770 kg (without batteries).

The dimensions of the packaging is as follows:

ULTRA120 B

A : 1760 mm

B : 1335 mm

C: 2135 mm

A

C

B

1.

Remove the outer packaging.

2.

The machine is fixed to the pallet with wedges which block the wheels.

3.

Remove the wedges.

4.

Use a chute to get the machine down from the pallet, pushing it backwards. Do not assemble the rear

squeegee before unloading the machine, and avoid violently jolting the brush base. To assemble the

squeegee, read the “ASSEMBLING THE SQUEEGEE” paragraph.

5.

Keep the pallet for any future transport needs.

ATTENTION: if the product is delivered in cardboard containers, handle the

packed product with suitable lifting means that comply with the legal

requirements.

WARNING: During this operation, check there are no people or objects near

the machine

2. HOW TO MOVE THE MACHINE

1.

Make sure the solution tank and the recovery tank are empty

2.

Make sure that the detergent can is empty (CDS version)

3.

Check that the brush head and squeegee are in the raised position

4.

Place it on a pallet using a chute

5.

Check that the key switch is in the "0" position and remove the key

6.

Engage the parking brake

7.

Secure the machine to the pallet using wooden wedges

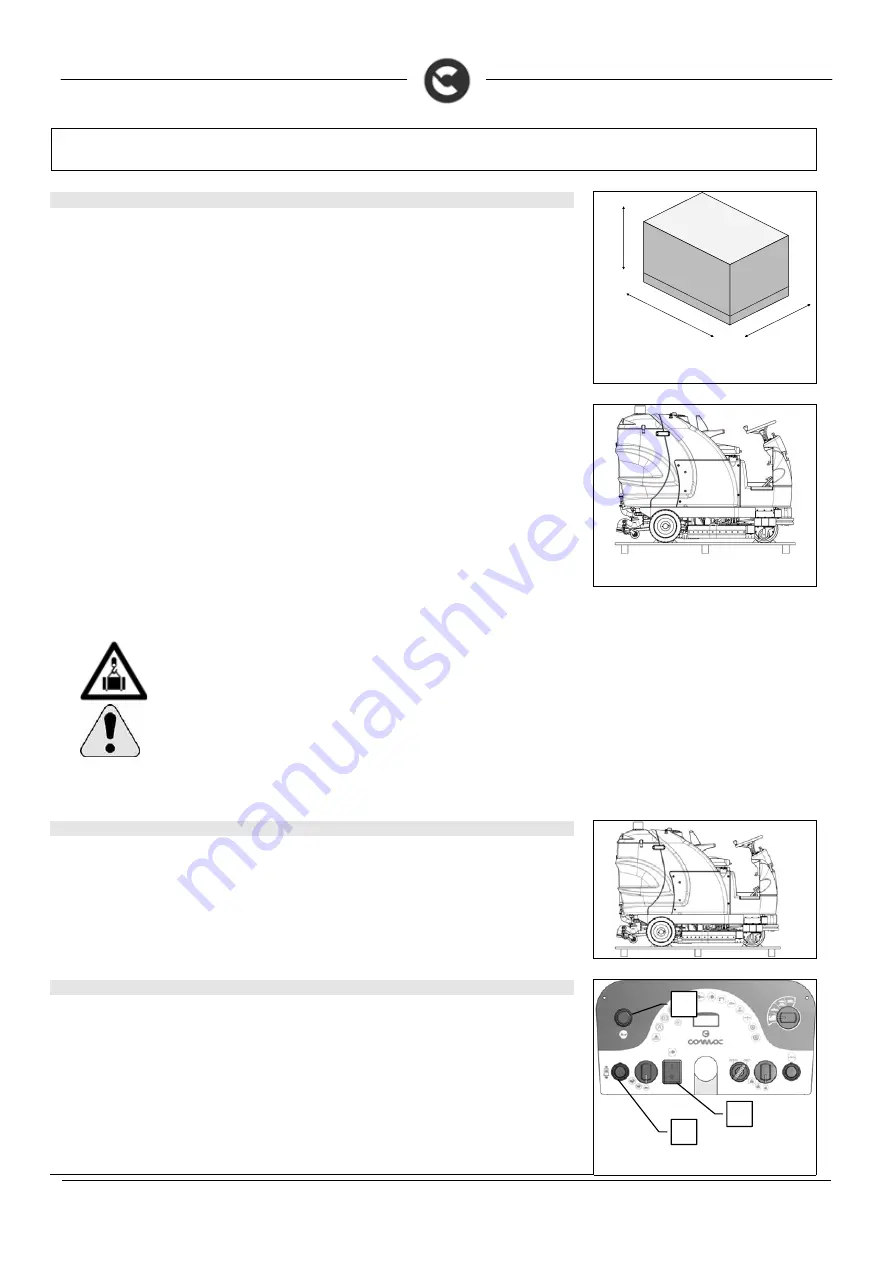

3. INSTRUMENT PANEL COMPONENTS

The instrument panel components are identified as follows:

1.

Horn button

2.

Toggle switch for turning the machine lights on/off

3.

Knob to control direction of machine movement (forward/reverse)

1

2

3