18

Plus 42 - 45 - 50 - 55 - 55S - 55E

11-2000

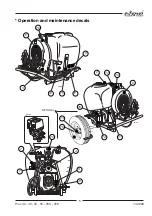

T2. RETURN TO TANK PIPING

It connects tap P6 to tank P1, at the point on which the hydraulic shaker is mounted.

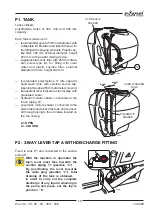

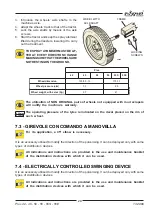

P7. 2-WAY LEVER FILLING TAP

It is mounted on pump P4 and connected to tank P1 through the filler piping T3.

T3

c

a

P7

a = OPEN

when the control lever is parallel at the

tap’s body

c = CLOSED

when the lever is perpendicular

to the tap.

It must normally remain in the closed

position.

It is only opened to carry out the

loading of the tank through the filler

piping (see point 8.3).

When the operation is complete, it

must be returned to the closed posi-

00138

tion.

T3. PIPING FOR THE LOADING

It connects tap P7 to tank P1 for the filling.

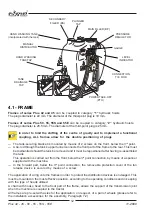

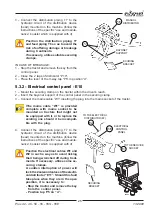

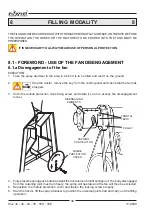

P8. SELF-CLEANING IN-LINE DELIVERY FILTER

It is mounted on tap P5 and connected to the distributor (P10/E10) through the feed piping (T6).

A ring nut locks the lid to the filter body. The self-cleaning and mixing tap is set below the lid and is fitted

with a control knob:

— OPEN (anticlockwise rotation) the tap to

carry out the draining or the mixing of powder

products;

— CLOSE (clockwise rotation) the tap in order

that the operations are not carried out.

Filter (filtering capacity of 250 lt/min.), with a 50-

mesh cartridge.

A soiled cartridge determines a lowering of the

operating pressure.

This malfunction is signalled by the relevant

gauge.

This machine device only filters the feed flow to

the heads, considerably reducing the chances

of cartridge clogging.

P8

c

a

T4

T6

P9

T5

00024