Chapter 7

7-4

7.2.2 Laser Light Emission Control

0020-0857

In this machine, the laser diode ON/OFF is controlled according to the laser light emission mode.

The laser light emission mode is determined based on the combination of the laser control signals (LD_CTL 0 to 2) that is output by the DC controller.

The laser driver IC receives the laser control signals from the DC controller and emits the laser diode according to the laser light emission mode.

7.2.3 Laser Light Intensity Control

0020-0858

In this machine, the laser light intensity is switched according to the rotational speed of the scanner motor.

The laser light intensity switch signal (LDPWRH) that is output by the DC controller controls switching the laser light intensity.

The laser driver IC receives the laser light intensity switch signal from the DC controller and switches the laser light intensity.

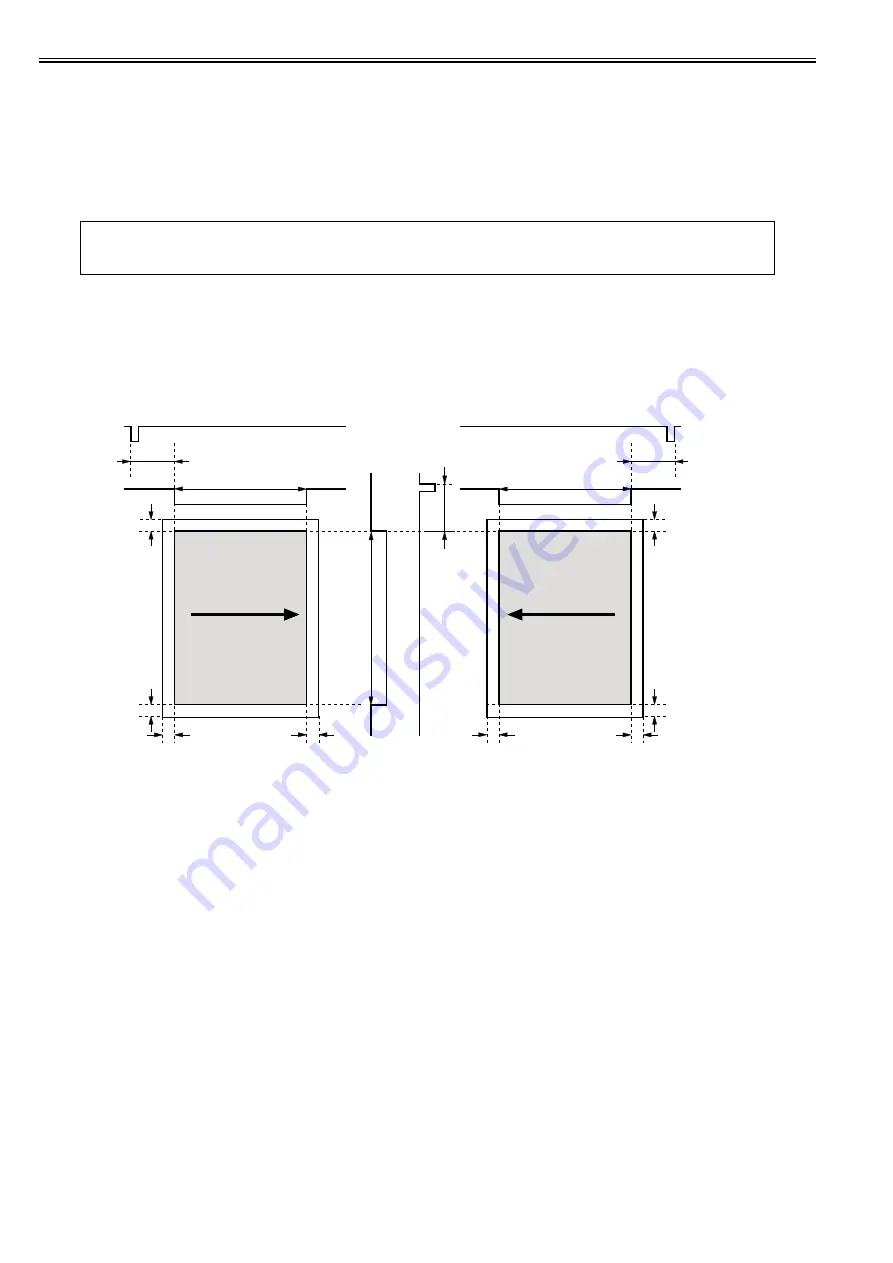

7.2.4 Image Masking Control

0019-5008

In the DC controller, the image masking control is performed to regulate laser beam emission in non-image area that BD detection is not performed on.

The DC controller puts the laser driver circuit into LD forced OFF mode while the laser beam scans the non-image area that BD detection is not performed on. This

is called the image masking status, and the laser diode does not emit light even if the video signals are sent because it is forcedly OFF in LD forced Off mode.

The timing to start the image masking control depends on the paper size information that DC controller receives from the main controller. (There is no cassette

paper size detection function in this equipment.)

F-7-3

- The colored area indicates the area where an image can be scanned by the laser beam.

- The times T1, T2, T3, T4 and T5 depend on the paper size.

- The T1 time depends on the color.

- If the main controller does not specify the paper size with a paper size command at manual feed pickup operation, the printer cannot detect the paper width. In

such a case, the T1 to T3 are automatically set for letter size but T5 is set according to the paper length detected by the manual feed paper sensor (SR707).

7.2.5 Failure Detection

0019-5009

In the DC controller, the failure in the laser diode is detected.

The laser driver IC converts the laser current of the laser diodes into voltage value (laser current output signal: PDOUT) during the initial APC period and sends it

to the DC controller.

If the voltage value equivalent to the laser current output signal is below the specified value, the DC controller presumes the laser diode failure, stops the printer

engine, and displays "E100 (optical unit failure)" on the control panel.

MEMO:

The process speed varies according to the paper type. (See 'Feed Speed Control' in Pickup and Feed System.)

When changing the process speed, the rotational speed of the scanner motor needs to be changed. If not switching the laser light intensity, a fault in image density

may occur.

2 mm

2 mm

2 m

m

2 m

m

/BDI

T3

T2

2 mm

2 mm

2 m

m

2 m

m

T2

/BDI

T1

T4

/T

OP

T5

Right/Left margin

masking

C/Bk Image masking

Y/M Image masking

T

op/Bottom

margin masking

Right/Left margin

masking

Scanning direction

Scanning direction

Содержание iR C1020 Series

Страница 1: ...Sep 8 2008 Service Manual iR C1020 Series iR C1021i ...

Страница 2: ......

Страница 6: ......

Страница 18: ...Contents ...

Страница 19: ...Chapter 1 Introduction ...

Страница 20: ......

Страница 22: ......

Страница 57: ...Chapter 2 Installation ...

Страница 58: ......

Страница 60: ......

Страница 73: ...Chapter 3 Basic Operation ...

Страница 74: ......

Страница 76: ......

Страница 81: ...Chapter 4 Main Controller ...

Страница 82: ......

Страница 84: ......

Страница 97: ...Chapter 5 Original Exposure System ...

Страница 98: ......

Страница 100: ......

Страница 112: ......

Страница 113: ...Chapter 6 Original Feeding System ...

Страница 114: ......

Страница 116: ......

Страница 132: ......

Страница 133: ...Chapter 7 Laser Exposure ...

Страница 134: ......

Страница 136: ......

Страница 143: ...Chapter 8 Image Formation ...

Страница 144: ......

Страница 146: ......

Страница 180: ......

Страница 181: ...Chapter 9 Pickup and Feed System ...

Страница 182: ......

Страница 213: ...Chapter 9 9 29 F 9 79 1 2 3 ...

Страница 214: ......

Страница 215: ...Chapter 10 Fixing System ...

Страница 216: ......

Страница 218: ......

Страница 233: ...Chapter 11 External and Controls ...

Страница 234: ......

Страница 263: ...Chapter 12 e maintenance imageWARE Remote ...

Страница 264: ......

Страница 266: ......

Страница 275: ...Chapter 12 12 9 F 12 27 ...

Страница 280: ......

Страница 281: ...Chapter 13 Maintenance and Inspection ...

Страница 282: ......

Страница 284: ......

Страница 286: ......

Страница 287: ...Chapter 14 Measurement and Adjustments ...

Страница 288: ......

Страница 290: ......

Страница 293: ...Chapter 15 Correcting Faulty Images ...

Страница 294: ......

Страница 296: ......

Страница 304: ...Chapter 15 15 8 15 3 2 2 Fans 0019 5064 F 15 11 T 15 3 Notation Name FM1 main unit fan FM2 duplex fan FM2 FM1 ...

Страница 313: ...Chapter 15 15 17 F 15 19 21 22 28 29 30 31 24 14 15 16 23 26 25 32 27 20 19 18 17 2 13 6 10 33 1 8 4 3 12 11 5 7 9 ...

Страница 317: ...Chapter 16 Error Code ...

Страница 318: ......

Страница 320: ......

Страница 331: ...Chapter 16 16 11 ...

Страница 332: ......

Страница 333: ...Chapter 17 Special Management Mode ...

Страница 334: ......

Страница 336: ......

Страница 343: ...Chapter 17 17 7 ...

Страница 344: ......

Страница 345: ...Chapter 18 Service Mode ...

Страница 346: ......

Страница 348: ......

Страница 388: ......

Страница 389: ...Chapter 19 Upgrading ...

Страница 390: ......

Страница 392: ......

Страница 396: ...Chapter 19 19 4 3 Click Next F 19 4 4 Select a USB connected device and click Next F 19 5 ...

Страница 397: ...Chapter 19 19 5 5 Click Start F 19 6 6 Click Yes F 19 7 Download will be started F 19 8 ...

Страница 399: ...Chapter 19 19 7 ...

Страница 400: ......

Страница 401: ...Chapter 20 Service Tools ...

Страница 402: ......

Страница 404: ......

Страница 407: ...Sep 8 2008 ...

Страница 408: ......