3. Refer to

“Flow of Determining the Procedure for Collecting Logs” on page 251

and when it is judged that collection

of the network packet logs is required, enable the network packet log collection function by following the procedure

shown below and start the function.

1. Enter a license in the following menu to enable network packet capture.

[Settings/Registration] > [Management Settings] > [License/Other] > [Register License]

NOTE:

Use the license issued by the Support Dept. of the sales company to activate it.

2. Enable the setting (ON) in the following menu.

[Settings/Registration] > [Preferences] > [Network] > [Store Network Packet Log]

3. Set "1" in the following service mode (Lv.2).

Service mode > COPIER > TEST > NET-CAP > CAPOFFON

4. Refer to

“Initial setting of the network packet log collection function” on page 256

, and configure the required option

settings.

5. Set "0" or "1" in the following service mode (Lv.2) to start capture of network packets.

Service mode > COPIER > TEST > NET-CAP > STT-STP

• 0: Not automatically collect at startup (factory default setting)

• 1: Automatically collects at startup

6. Execute the following service mode (Lv.2) to check the status of the capture.

Service mode > COPIER > TEST > NET-CAP > CAPSTATE

The following types of status are displayed.

• RUNNING: Packets are being captured.

• STOP: Packet capturing is stopped.

• HDDFULL: The maximum amount of 1 GB of packets has been captured.

4. When an instruction to change the automatic log settings is given by the Support Dept. of the sales company, change

“Automatic Log Settings” on page 255

● Automatic Log Settings

Automatic log is collected triggered by "occurrence of an unexpected error", "occurrence of an error code" or "restart of the

machine".

If you want to change the triggers, change the setting in the following service mode.

COPIER > Function > DBG-LOG > LOG-TRIG

However, there is no need to change the setting unless otherwise instructed by the Support Dept. of the sales company.

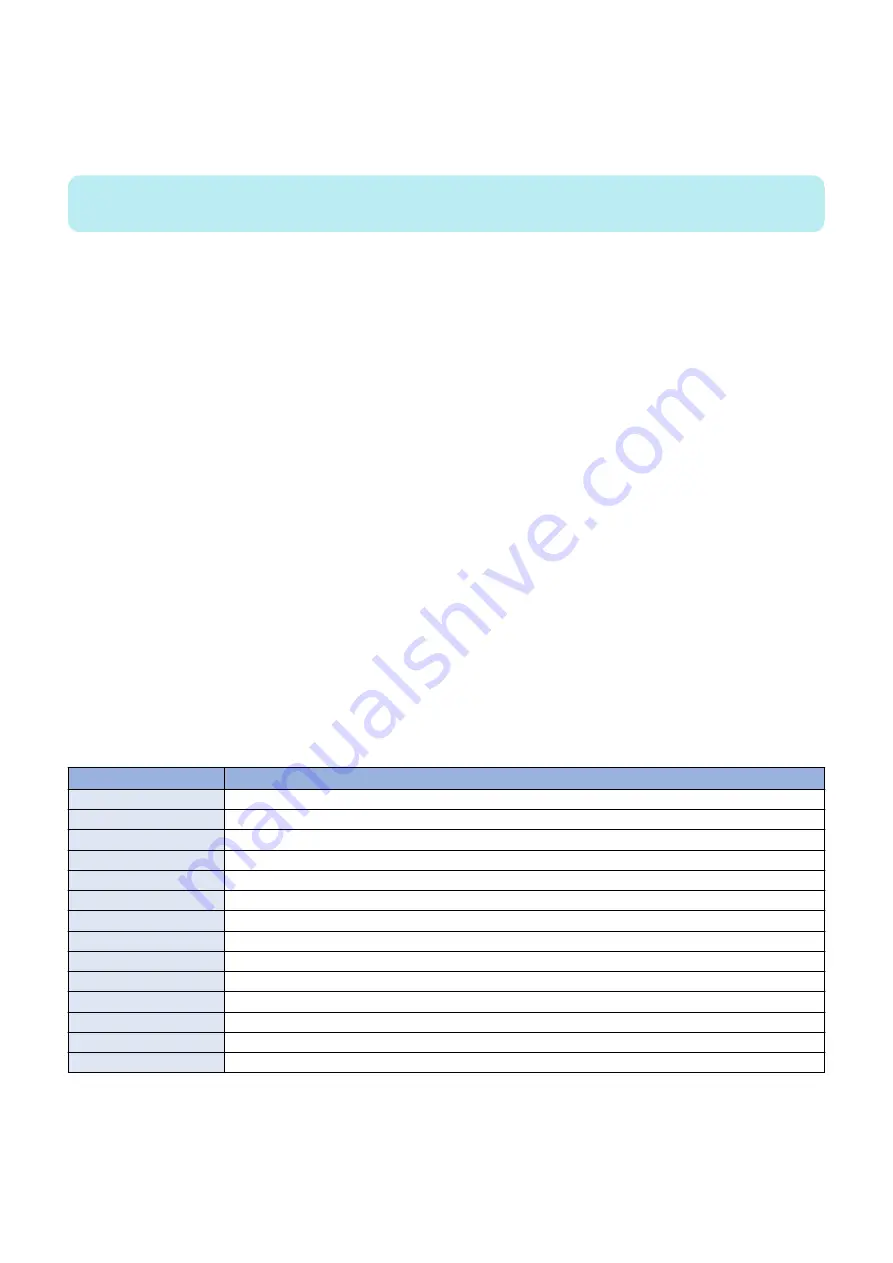

The events that trigger collection of automatic logs and their setting values are shown below.

List of conditions for automatic saving of logs and setting values

Setting value

Event condition for saving automatic log

101 (Default setting)

When an unexpected error occurs, an error code occurs, or the machine is restarted

111

Only when an unexpected error occurs

121

Only when an error code occurs

131

Only when the machine is restarted

201

When an unexpected error occurs, an error code occurs, the machine is restarted, or an alarm occurs

211

When an unexpected error occurs or an alarm occurs

221

When an error code occurs or an alarm occurs

231

When the machine is restarted or an alarm occurs

291

Only when an alarm occurs

301

When an unexpected error occurs, an error code occurs, the machine is restarted, or a jam occurs

311

When an unexpected error occurs or a jam occurs

321

When an error code occurs or a jam occurs

331

When the machine is restarted or a jam occurs

391

Only when a jam occurs

The procedure for changing the log auto save conditions with LOG-TRIG is indicated below.

1. Press [LOG-TRIG], enter the value for the conditions you want to set, and press [OK].

"ACTIVE!" flashes in the display column, and the log settings in the machine are changed.

2. When [OK!] is displayed in the display column, the work is complete.

If the processing fails, "NG" is displayed. It is not necessary to restart the device.

6. Troubleshooting

255

Содержание imageRUNNER ADVANCE 525 I

Страница 1: ...Revision 1 0 iR ADV 715 615 525 Series Service Manual ...

Страница 15: ...Product Overview 1 Product Lineup 6 Specifications 9 Parts Name 14 ...

Страница 75: ... Paper Path Model with Built in Finisher Paper Path Model with Built in Finisher 2 Technology 65 ...

Страница 95: ...Periodical Service 3 Periodically Replaced Parts 86 Consumable Parts List 87 ...

Страница 120: ... Procedure 1 3x Removing the Front Cover Procedure 1 2x 2 4 Parts Replacement and Cleaning 110 ...

Страница 122: ...2 1x 3x 3 4 Parts Replacement and Cleaning 112 ...

Страница 124: ...1 2 3 4 Parts Replacement and Cleaning 114 ...

Страница 125: ...4 Removing the Control Panel Procedure 1 2 4 Parts Replacement and Cleaning 115 ...

Страница 126: ...3 2x 4 3x 2x 4 Parts Replacement and Cleaning 116 ...

Страница 127: ...5 6 CAUTION Do not drop the Control Panel while turning over it 4 Parts Replacement and Cleaning 117 ...

Страница 128: ...7 1x 1x 8 2x 4 Parts Replacement and Cleaning 118 ...

Страница 130: ...1 2 3 2x 4 Parts Replacement and Cleaning 120 ...

Страница 136: ... Procedure 1 2 1x NOTE Check the position of the claw in the figure 4 Parts Replacement and Cleaning 126 ...

Страница 169: ...23 Press the A part and remove the Feed Frame Unit A 4 Parts Replacement and Cleaning 159 ...

Страница 180: ...22 Press the A part and remove the Feed Frame Unit A 4 Parts Replacement and Cleaning 170 ...

Страница 190: ...21 Press the A part and remove the Feed Frame Unit A 4 Parts Replacement and Cleaning 180 ...

Страница 196: ...3 4 Parts Replacement and Cleaning 186 ...

Страница 204: ...2 4x 16x 3 4 Parts Replacement and Cleaning 194 ...

Страница 210: ... Procedure 1 2x 1x 4 Parts Replacement and Cleaning 200 ...

Страница 211: ...2 2x 3x 1x 4 Parts Replacement and Cleaning 201 ...

Страница 212: ...3 CAUTION Do not touch the speaker part A of the Fax unit A 2x 1x 4 Parts Replacement and Cleaning 202 ...

Страница 215: ...Image Formation System Removing the Transfer Unit Procedure 1 2 3 1x 4 Parts Replacement and Cleaning 205 ...

Страница 217: ...2 1x 4 Parts Replacement and Cleaning 207 ...

Страница 221: ...5 Removing the Low Voltage Power Supply PCB on page 195 Procedure 1 4x 1x 4 Parts Replacement and Cleaning 211 ...

Страница 223: ...2 1x 3 4 1x 4 Parts Replacement and Cleaning 213 ...

Страница 226: ... Procedure 1 2 3 1x 4 Parts Replacement and Cleaning 216 ...

Страница 227: ...4 11x 5 1x 6 1x 4 Parts Replacement and Cleaning 217 ...

Страница 228: ...7 6x 1x 8 4 Parts Replacement and Cleaning 218 ...

Страница 238: ... Procedure 1 2x 2x 2 4 Parts Replacement and Cleaning 228 ...

Страница 240: ... Procedure 1 2 3 1x 4 Parts Replacement and Cleaning 230 ...

Страница 241: ...4 5 3x 1x 2x 4 Parts Replacement and Cleaning 231 ...

Страница 242: ...Adjustment 5 Pickup Feed System 233 Actions at Parts Replacement 235 ...

Страница 251: ...Troubleshooting 6 Initial Check 242 Test Print 243 Debug Log 248 ...

Страница 277: ...Error Jam Alarm 7 Overview 268 Error Code 271 Error Code FAX 324 Alarm Code 327 Jam Code 336 ...

Страница 598: ...6 7 8 1x 9 NOTE Use the screw removed in steps 3 1x 9 Installation 588 ...

Страница 602: ...2 3 2x 4 3x 2x 9 Installation 592 ...

Страница 603: ...5 6 7 1x 1x 8 2x 9 Installation 593 ...

Страница 604: ...9 6x 10 2x Installing the NFC Kit 1 1x 9 Installation 594 ...

Страница 605: ...2 1x 3 TP M3x4 1x 4 1x 9 Installation 595 ...

Страница 606: ... Installing the Control Panel 1 2x 2 6x 9 Installation 596 ...

Страница 607: ...3 2x 4 1x 1x 5 6 9 Installation 597 ...

Страница 619: ...21 22 Without the Finisher With the Finisher 9 Installation 609 ...

Страница 638: ...APPENDICES Service Tools 629 General Circuit Diagram 630 Soft counter specifications 635 Removal 639 ...

Страница 639: ...Service Tools Special Tools None Solvents and Oils None Service Tools 629 ...