2. Installation Manual

- 8 -

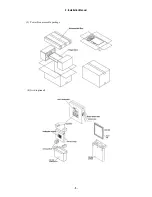

4.2 System

Installation

Procedures

No.

Step

Conditions and Checkpoints

Reference Section

1

Unpacking and checking the

product’s constituent parts

-There must be no missing parts, damage,

dents, etc.

-There must no color changes in the shock

sensor.

2

Connect the Imaging Unit

and the Power Box

-Handle the instrument carefully, as it may

be damaged if something is hit against it,

dropped or receives the strong jolt.

-The cable must be routed in such a way that

no unreasonable loads are brought to bear

upon them.

3

Connect the Power Box and

the Control PC

-The cable must be routed in such a way that

no unreasonable loads are brought to bear

upon them.

4

Connect the Power Box and

the X-ray generators

-The manufacturer of the X-ray generators

must be asked to handle the connections

with the generators.

5

Check date and time

- Date and time must be changed according

to the area where the instrument is installed.

“(1) Checking and

Setting the Date and

Time” in section 5.6.

6

Check the software

program’s version

-The compatibility of the sensor unit and the

Control PC must be checked on the

compatibility list, and the software program

must be installed or upgrade as required.

“(2) Checking the

Firmware Version” in

section 5.6.

7

Identifying the Imaging Unit

(input the sensor serial

numbers)

“(6) Identifying the

Sensor Units” in section

5.6.

8

Enter control PC serial

number.

“(7) Entering Control

PC Serial Number” in

section 5.6.

(9)

Adjusting the timing with X-

ray generator

-No required usually.

10

Calibration

-No error must be displayed.

Operation Manual

11

Setting the Fixed ROI Areas

If necessary, set the ROI area.

12

Set exposure parameter table -Set it in consultation with the technician.

“(8) Table Setup

Setting” in section 5.6.

13

Set annotation

-Set it in consultation with the technician.

“(9) Performing the

Annotation Setting” in

section 5.6.

14

Connect the network and set

the output destination

“(10) Network

Connections” in section

5.6.

15 Startup

settings

“(5) Set Up Startup

Menu” in section 5.6.

16

Exposure testing

-The data must be sent to the printer and

storage and the image quality must be

checked.

Section 5.7 Image

Quality.

17

Check the linearity of the

transferred image density.

“(11) Linearity Check

Image Density” in

section 5.6.

18

Operation unit Gamma

correction

“(12) Operation Unit

Gamma Correction” in

section 5.6.

19

Body parts settings

-The engineer in charge must be consulted

prior to perform these settings.

Operation Manual

20

Check and set the system

settings.

-The engineer in charge must be consulted

prior to perform these settings.

Each section in section

5.6 Settings.

21

Total adjustments and delete

the unnecessary data.

-Conform according to the check sheet.

-Delete the unnecessary data.

Section 5.8 Post-

installation check.

22 Cleaning

Содержание CXDI-50C

Страница 15: ......

Страница 23: ...2 Installation Manual 6 3 Power Box assemble package 4 Grid optional ...

Страница 35: ...2 Installation Manual 18 When normal imaging When timeout due to RX_REQ not negating ...

Страница 63: ...2 Installation Manual 46 Fig 3 Input parameters ...

Страница 115: ...2 Installation Manual 98 2 Power Box Unit mm Mass 4 2Kg ...

Страница 116: ...2 Installation Manual 99 3 Remote Switch Unit mm Mass 0 5Kg 4 Grid Optional 508 27 452 Unit mm Mass 0 9Kg Frame ...

Страница 118: ......

Страница 138: ...4 Repair Guide 3 Do not touch the tabs when replacing the sensor cable Tabs in Enlarged View Sensor Cable ...

Страница 163: ......

Страница 167: ...CXDI SYSTEM 1 2 Rev 04 Key No 5 Key No 6 Key No 7 Key No 8 Key No 9 Canon Inc ...

Страница 186: ......

Страница 188: ......

Страница 189: ...Content 1 Gathering Information about Problems 1 2 How to back up and recover the system 3 ...