14

9. SAFETY PRECAUTION

CAUTION

THE OPERATION OF A GAS FURNACE MUST BE VERIFIED FOR ACCEPTABLE OPERATION BEFORE

AND AFTER INSTALLATION OF THE CADDY ADD-ON APPLIANCE BY A GAS FITTER WHO IS

RECOGNIZED BY THE REGULATORY AUTHORITY.

CAUTION

DO NOT CONNECT TO ANY GAS FURNACE THAT HAS NOT BEEN CERTIFIED INITIALLY AS COMPLYING

WITH CGA STANDARD CAN/CGA-2.3 OR ITS PRECEDENTS.

10. INTRODUCTION

The wood burning Caddy Add-on furnace is approved for in-line connection to an existing oil furnace or any gas or

electric furnace with a maximum heating capacity of 120,000 BTU/h. (35.17 kW)

10.1. BLOWER OF THE EXISTING FURNACE

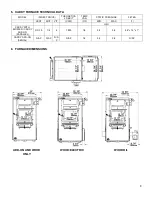

The theoretical air flow in the hot air plenum blower of the existing furnace must be at least 1,900 CFM when the

external static pressure is adjusted to 0,2" and to 0,5" of water column.

Some adjustment on the motor and blower of the existing furnace may be necessary. In this case, the following rules

apply:

•

On a belt-driven system, blower pulleys and motor pulleys may be changed to do the adjustment.

•

On a direct-drive system, the motor shall not be changed; however, the speed of the motor may be increased or

decreased.

CAUTION

THE BLOWER OF THE EXISTING FURNACE ITSELF SHALL NOT BE CHANGED.

WARNING

THE ELECTRICAL CURRENT FLOWING THROUGH THE BLOWER MOTOR SHALL NOT EXCEED THE NAME

PLATE RATING.

11. APPLIANCE INSTALLATION

If the exiting furnace must be modified, the following standards must be respected:

Wood-oil

•

NFPA 31: Standard for the installation of oil-burning equipment.

•

CSA B.139: Installation code for oil-burning equipment.

Wood-gas

•

National Fuel Gas Code, ANSI Z223.1/ NFPA 54.

•

CAN/CGA-B149.1 & CAN/CGA-B149.2 : Natural Gas & Propane Installation Code et Propane Storage & Handling

Code.

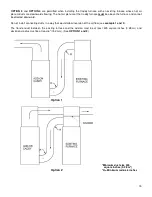

11.1. MATCHING THE TRANSFER DUCT BETWEEN THE TWO HEAT GENERATORS

This furnace is certified only for installation in configuration presented in

OPTION 1, 2, 3 and 4

of this section.

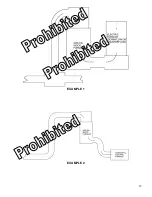

Configurations presented in

Examples 1 and 2

of this section are prohibited.

Install the plenum and heating ducts in line as in

OPTION 1

of this section. Series connection (

OPTION 2

)

should be

considered ONLY if in line connection (

OPTION 1)

is not possible.

If the ducts are installed in series (

OPTION 2

) and the existing furnace’s fan limit control is mounted on the plenum, the

divider in the plenum must be installed at least 5" (127 mm) above the fan limit control. This divider must be air tight.

Содержание PF01015

Страница 10: ...10 ADD ON WOOD ONLY WOOD ELECTRIC WOOD OIL ...

Страница 13: ...13 INSTALLATION AND OPERATION INSTRUCTIONS CADDY ADD ON SERIAL INSTALLATION PF01015 ...

Страница 16: ...16 Option 3 Option 4 ...

Страница 17: ...17 EXAMPLE 1 EXAMPLE 2 ...

Страница 23: ...23 REQUIRES 2 RELAY SPNO SPNC WHITE ROGERS P N 90 380 NOT INCLUDED AND 24V AVAILABLE ON EXISTING FURNACE ...

Страница 24: ...24 13 ELECTRICAL DIAGRAM FOR SERIAL FURNACE VIA MOTOR REQUIRES 1 RELAY 51035 WITH 1 JUNCTION BOX NOT INCLUDED ...

Страница 63: ...63 20 GENERAL ELECTRICAL DIAGRAM STANDALONE FURNACE ...

Страница 64: ...64 21 ELECTRICAL DIAGRAM FOR PARALLEL FURNACE ...

Страница 65: ...65 22 ELECTRICAL DIAGRAM FOR ELECTRIC UNIT ...

Страница 78: ...78 31 ELECTRICAL DIAGRAM BECKETT OIL UNIT ...

Страница 79: ...79 32 ELECTRICAL DIAGRAM RIELLO OIL UNIT ...

Страница 81: ...81 33 4 AIR CONDITIONNING DAMPER 33 5 HUMIDIFIER 33 6 HEAT PUMP ...

Страница 82: ...82 34 EXPLODED VIEW AND PART LIST ...

Страница 83: ...83 ...

Страница 84: ...84 ...

Страница 85: ...85 ...

Страница 86: ...86 ...

Страница 87: ...87 ...

Страница 88: ...88 ...

Страница 89: ...89 ...