73

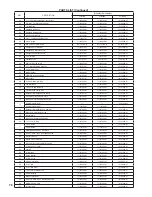

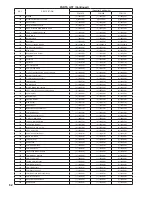

TablE 1.: HarD lOCKOuT CODEs DisPlaYED

CODE

CONDITION

POSSIBLE CAUSES

E 00

A flame signal was present when there should

be no flame.

• Defective gas valve - make sure inlet pressure is below maximum on rating plate

before replacing valve.

E 02

Flame failure after 5 tries to restart

• No gas pressure

• Gas pressure under minimum value shown on rating plate

• Gas line not completely purged of air

• Defective Electrode

• Loose burner ground connection

• Defective Ignition Cable

• Defective gas valve (check for 24 VDC at harness during trial for ignition before

replacing valve)

• Air-fuel mixture out of adjustment - consult factory

E 03

Gas valve error

• Loose or defective gas valve harness. Check electrical connections.

• Defective gas valve (check for 24 VDC at harness during trial for ignition before

replacing valve)

E 04

Power failure occurred after lockout

• Some other error on this list occurred and power to the boiler was then

interrupted. Reset control and see if hard lockout reoccurs.

E 05

E 06

E 07

E 11

Internal control failure

• Reset the control. If problem reoccurs, replace the MCBA.

E 12

Low water cut-off circuit open

• If yellow light on LWCO is on, system is low on water

• If neither yellow nor green light is on, check LWCO harness and check for

24VAC across AT140 transformer

E 13

E 14

E 15

E 16

E 17

Internal control failure

• Reset the control. If problem reoccurs, replace the MCBA.

E 18

MCBA supply sensor detected temperatures in

excess of 200°F for an extended period of time

• See possible causes for “b18” error. Also, check safety limit for proper operation.

E 19

MCBA return sensor detected temperatures in

excess of 200°F for an extended period of time

• See possible causes for “b19” error.

E 28

Blower is not running when it should or fan speed

signal not being detected by MCBA

• Loose connection in 120 VAC fan wiring

• Loose or miswired fan speed harness

• Defective fan

E 29

Blower fan speed has not returned to zero rpm

• Miswired fan speed harness

• Defective fan

E 31

Shorted supply temperature sensor

• Shorted or miswired supply sensor wiring

• Defective supply sensor

E 32

Shorted return temperature sensor

• Shorted or miswired return sensor wiring

• Defective return sensor

E 35

Flue gas temperature sensor short circuit

• Shorted or miswired flue temp sensor wiring

• Defective flue temp sensor

E 36

Supply water temperature sensor circuit open

• Loose or miswired supply sensor wiring

• Defective supply sensor

E 37

Return water temperature sensor circuit open

• Loose or miswired return sensor wiring

• Defective return sensor

E 40

Flue gas temperature sensor circuit open

• Loose or miswired flue temp sensor wiring

• Defective flue temp sensor

E 44

Internal control failure

• Reset the control. If problem reoccurs, replace the MCBA.

E 52

Flue gas temperature over 230°F

• Heat exchanger needs to be cleaned

• Boiler over-fired

• Air-fuel mixture out of adjustment - consult factory

E 60

Internal control failure

• Reset the control. If problem reoccurs, replace the MCBA.

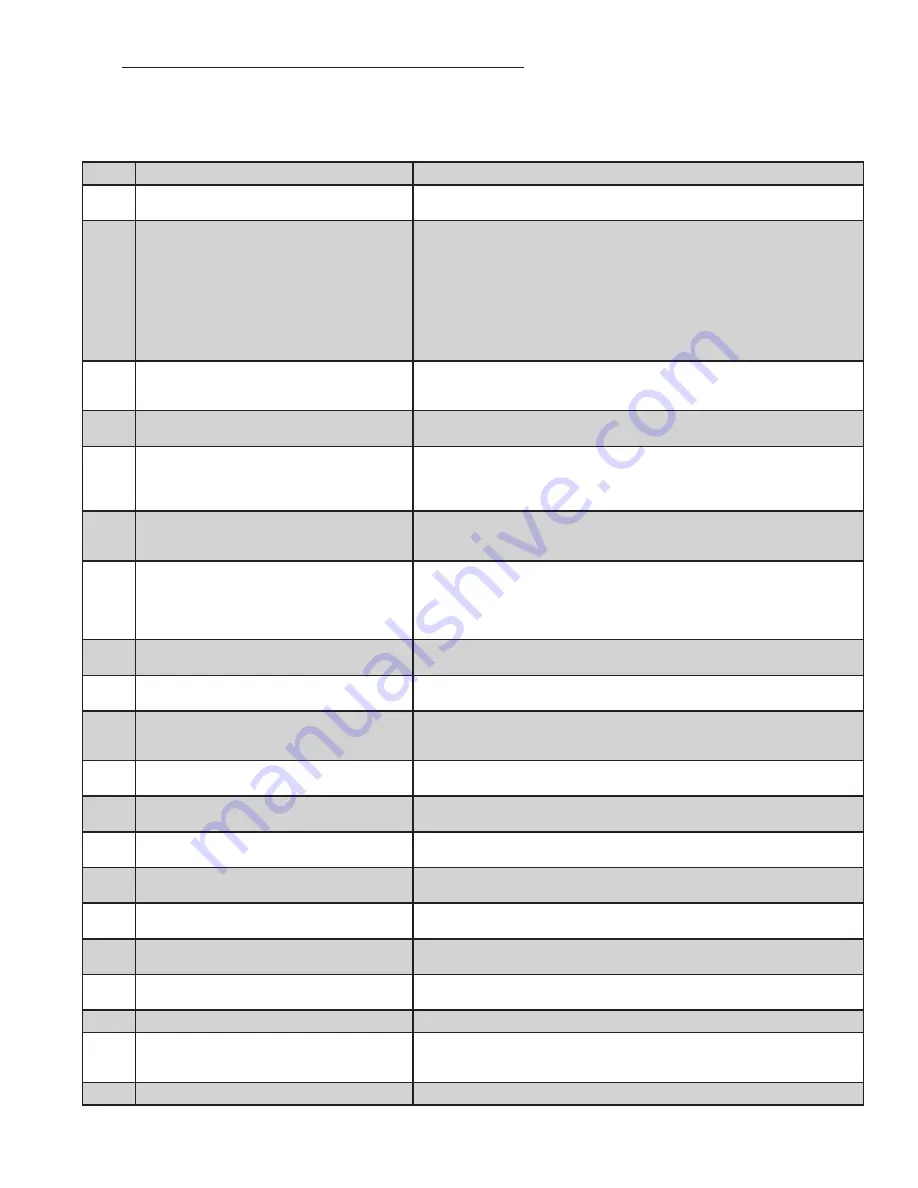

C. Trouble shooting problems where a hard lockout code is displayed. When a hard lockout occurs, the boiler

will shut down and the display will flash the letter “E” followed by a two digit service code. Once the condition

that caused the lockout is corrected, the boiler will need to be manually reset using the RESET button on the

display.

Содержание FREEDOM

Страница 8: ...8 Figure 1 Wall Mounting Hole locations ...

Страница 9: ...9 Figure 5 2 Boiler Mounting Hardware ...

Страница 11: ...11 Figure 6 1 Boiler Installed In A Confined Space Ventilation Air From Inside ...

Страница 24: ...24 Figure 7 20 Installation of Reducing Elbow on Concentric Boiler Collar Figure 7 21 Dimension L ...

Страница 34: ...34 Figure 7 35b Cutting Vertical Terminal Figure 7 35c Completing Vertical Terminal Installation ...

Страница 42: ...42 FIGURE 7 51 CONDENSATE PIPING ARRANGEMENT ...

Страница 55: ...55 Figure 10 1 Wiring Connections Diagram ...

Страница 56: ...56 Figure 10 2 Ladder Diagram ...

Страница 57: ...57 Figure 10 3 Wiring of Isolation Relay for Control of Two Heating Circulators ...

Страница 60: ...60 FCM Series Lighting and Operating Instructions ...

Страница 66: ...66 FIGURE 12 2 BASIC MENU TREE ...

Страница 75: ...75 ...

Страница 77: ...77 ...

Страница 79: ...79 ...

Страница 80: ...80 ...

Страница 81: ...81 ...

Страница 83: ...83 150 151 152 153 154 155 ...

Страница 84: ...84 156 157 158 159 160 161 ...

Страница 85: ...85 162 ...