CHAPTER 7 MAINTENANCE MODE

CONTENTS

7.1

CONTROL PANEL...........................................................................................................7-1

7.2

ENTRY INTO THE MAINTENANCE MODE ....................................................................7-3

7.3

LIST OF MAINTENANCE-MODE FUNCTIONS ..............................................................7-4

7.4

USER-ACCESS TO THE MAINTENANCE MODE..........................................................7-5

7.5

DETAILED DESCRIPTION OF MAINTENANCE-MODE FUNCTIONS ..........................7-6

7.5.1

EEPROM Parameter Initialization ........................................................................7-6

7.5.2

Printout of Scanning Compensation Data ............................................................7-7

7.5.3

Movement of CCD Unit to the Transport Position ................................................7-9

7.5.4

ADF Performance Test ......................................................................................7-10

7.5.5

Test Pattern 1.....................................................................................................7-11

7.5.6

Firmware Switch Setting and Printout ................................................................7-12

7.5.7

Operational Check of LCD .................................................................................7-15

7.5.8

Operational Check of Control Panel PCB ..........................................................7-16

7.5.9

Sensor Operational Check .................................................................................7-17

7.5.10 Fine Adjustment of Scanning Start/End Position ...............................................7-18

7.5.11 CCD Scanner Area Setting ................................................................................7-19

7.5.12 Setting the Sensing Reference Level of the Ink Empty Sensor .........................7-20

7.5.13 Alignment of Vertical Print Lines ........................................................................7-21

7.5.14 Updating of Paper Feeding Correction Value.....................................................7-23

7.5.15 Updating of Head Property Information..............................................................7-25

7.5.16 Initial Adjustment of PWM Value (Aging of the Carriage) ..................................7-26

7.5.17 EEPROM Customizing .......................................................................................7-27

7.5.18 Display of the Equipment's Log Information.......................................................7-28

7.5.19 Equipment Error Code Indication .......................................................................7-29

7.5.20 Output of Transmission Log to the Telephone Line ...........................................7-29

7.5.21 Cancellation of the Pin TX Lock Mode (Not applicable to American models)....7-30

Содержание MFC-5200C

Страница 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC5200C MFC890 ...

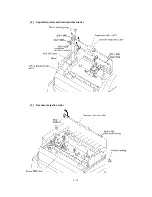

Страница 7: ...CHAPTER 1 PARTS NAMES FUNCTIONS ...

Страница 8: ...CHAPTER 1 PARTS NAMES FUNCTIONS CONTENTS 1 1 EQUIPMENT OUTLINE 1 1 1 2 CONTROL PANEL 1 3 ...

Страница 13: ...CHAPTER 2 SPECIFICATIONS ...

Страница 18: ...2 4 2 1 4 Environmental Condition ...

Страница 23: ...CHAPTER 3 INSTALLATION ...

Страница 26: ...3 2 3 2 UNPACKING THE MACHINE The equipment consists of the following major components ...

Страница 34: ...CHAPTER 4 THEORY OF OPERATION ...

Страница 54: ...CHAPTER 5 MAINTENANCE ...

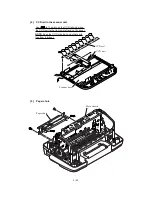

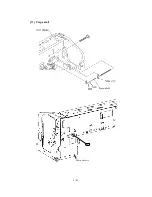

Страница 60: ...CHAPTER 6 DISASSEMBLY REASSEMBLY LUBRICATION AND ADJUSTMENT ...

Страница 141: ...6 79 2 Separation roller and document feed roller 3 Document ejection roller ...

Страница 146: ...6 84 11 Purge shaft EM4 Main chassis ...

Страница 147: ...6 85 12 Carriage Viewed from the rear After lubrication more this to the right and left Carriage EM2 EM4 EM4 EM3 EM3 ...

Страница 151: ...CHAPTER 7 MAINTENANCE MODE ...

Страница 160: ...7 8 Scanning Compensation Data List ...

Страница 174: ...7 22 Vertical Alignment Check Pattern ...

Страница 176: ...7 24 Paper Feeding Check Patterns for the Paper Feed Roller and Paper Ejection Roller Pattern A Pattern B ...

Страница 183: ...CHAPTER 8 ERROR INDICATION AND TROUBLESHOOTING ...

Страница 213: ...8 29 4 Close the manual feed cover ...

Страница 214: ...MFC5200C MFC890 Appendix 1 Serial No Descriptions ...

Страница 215: ...SERIAL NO DESCRIPTIONS The descriptions as below shows how to read labels on each place 1 SET Location ...

Страница 216: ... 2 PRINTER HEAD UNIT Location ...

Страница 228: ...MFC5200C MFC890 Appendix 3 EEPROM Customizing Codes ...

Страница 231: ...MFC5200C MFC890 Appendix 4 Firmware Switches WSW ...

Страница 274: ...MFC5200C MFC890 Appendix 5 Re Packing Instructions ...

Страница 276: ... 8 Place the machine in the original box with the original packaging material ...

Страница 277: ...MFC5200C MFC890 Appendix 6 Wiring Diagram ...

Страница 280: ...A Main PCB 1 4 MFC5200C ...

Страница 281: ...A Main PCB 2 4 MFC5200C ...

Страница 282: ...A Main PCB 3 4 MFC5200C ...

Страница 283: ...A Main PCB 4 4 MFC5200C ...

Страница 284: ...B Driver PCB 1 2 ...

Страница 285: ...B Driver PCB 2 2 ...

Страница 286: ...C NCU PCB MFC5200C ...

Страница 287: ...D Control Panel PCB 1 2 MFC5200C ...

Страница 288: ...D Control Panel PCB 1 2 MFC890 ...

Страница 289: ...D Control Panel PCB 2 2 ...

Страница 290: ...E Power Supply PCB MFC5200C ...

Страница 291: ...F Carriage PCB ...

Страница 292: ...G Media PCB 1 2 ...

Страница 293: ...G Media PCB 2 2 ...

Страница 294: ...Aug 02 SM FAX013 1 8CA503 Printed in Japan ...