20

BA-077/1EN M6X.20XX

3 - How to operate the machine

3.5.2) Setting the stop dimension

• Select a suitable screw (

E29)

depending on the desired drilling depth

• Turn screw to the desired dimension Z in the drill and lock using the counter nut

a) Drilling depth

=

13

mm

Work piece thickness

=

X

mm

=

> Z = X

b) Drilling depth

=

Y

mm

Work piece thickness

=

X

mm

=

> Z = X + 13 - Y

• Check dimension with a test drilling

• Label revolver handle

(E16)

using the included stickers

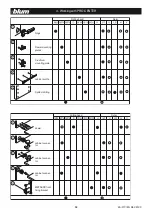

3.6 - Pre-setting revolver for work top setting

3.6.1) The dimensions for drilling positions

9.5

,

20

,

22.5

,

37

and for horizontal

drilling

(H)

are factory set.

• 3 additional dimensions can also be pre-set

• 3 stop rods

(E30)

are enclosed

3.6.2) Cutting stop rods to size

• The desired drilling position should be pre-set:

Drilling position [mm]

X [mm]

5 - 37

0

37 - 62

25

62 - 87

50

87 - 112

75

112 - 125

90

• Mark dimension X on the stop rod

(E30)

as shown in the top picture

• Cut the stop rod to the length using a hack saw and de-burr using a file

3.6.3) Screwing the re-sized stop rod

(E30)

into the revolver

• Loosen the clamping lever

(E10)

• Pull out work table completely

• Remove the cover

(E12)

in the work table

• Now fully screw the stop rod into a free drill hole in the revolver