12

BA-077/1EN M6X.20XX

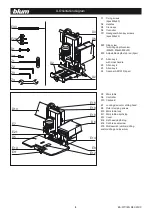

2.3.3) Checking motor rotation

ATTENTION

During the following procedure, keep your hands away from the work

area (A) of the machine.

• Main switch

(E1)

at Pos.

I

• Set mode switch

(E2)

to Pos.

I

(operation)

• If the control light for vertical drilling

(E6)

is flashing, tighten the spindle clamp screw

(E7)

• Briefly press the start button

(E3)

• The motor fan must turn in the direction of the arrow

(D9)

2 - Setting up PRO-CENTER

2.3.4) Correcting motor rotation

• If the motor rotation is wrong:

• Main switch

(E1)

at Pos.

0

• Interchange two phases for connection cable

(only by an authorised electrician)

• Recheck the motor rotation.

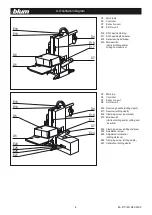

2.4.1) Connecting the extraction hose to the extraction system on the extraction

port

(D7)

of the machine (Ø 50 mm)

• Secure hose using the hose clamp

• Make sure that the air velocity for the extraction system is at least 20 m/s

2.4 - Dust extraction

ATTENTION

The machine must be connected to a dust extraction system!

Important

The extraction hose must be laid so that the extraction port

(D7)

is not

encumbered

ATTENTION

The electrical connection must be performed by a qualified electrician!

• In order for the machine to be operated only with the extraction system

2.4.2) Attaching the extraction system to the controller of PRO-CENTER 2000

turned on, terminals 12 and 18 (see electrical diagram) must be connected to a

potential-free contact of the dust extraction controller.

!