CB-100-1

63

6.1

Extension module for pressure control

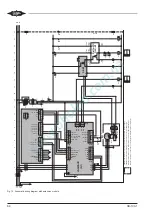

Graphical explanations of the control functions of the

extension module for pressure control described in the

following sections, see figure 17, page 64.

Basic function and minimum settings

If the extension module for pressure control is connec-

ted with the VARIPACK frequency inverter, this is im-

mediately detected by the VARIPACK frequency in-

verter which then enables the relevant parameters for

the extension module.

Apart from the basic settings, at least the following

parameters must be set for direct control:

• Refrigerant

• Evaporation temperature

• Evaporation temperature limiter (pump down)

• Condensing temperature

The compressor control is based on the so-called pump

down logic. For this, the digital start input (DI1) must be

permanently closed or can be used to release a control

switch. The compressor is switched on as soon as the

evaporation temperature exceeds the setpoint and

stops when the evaporation temperature falls below the

set value of the evaporation temperature limiter (pump

down).

In operation, the VARIPACK frequency inverter controls

the set evaporation temperature by regulating the com-

pressor frequency and by switching on/off the fixed fre-

quency compressor (relay FsC2, X5: 1 and 2). The reg-

ulation speed can be adjusted to the requirements by

setting the P band.

The set condensing temperature can be regulated via

the analogue output by means of the 0 .. 10 V signal. In

order to guarantee the most efficient level of operation,

it is recommended to set the minimum allowable con-

densing temperature of the compressors if the system

allows doing so. If the condensing temperature ex-

ceeds the setpoint, the rotation speed of the fans is in-

creased accordingly. By adjusting the P band to the

system inertia, the quality of the control can be optim-

ized. In addition, a minimum fan speed can be set, if

necessary.

"Evaporation temperature setpoint 2"

By switching the input DI3, the evaporation temperature

setpoint 2 is activated.

"Condensing temperature setpoint 2"

By switching the input DI4, the condensing temperature

setpoint 2 is activated. This value can be used, for ex-

ample, as setpoint for heat recovery.

"Condensing temperature limiter"

The condensing temperature limiter reduces the com-

pressor frequency as soon as the set condensing tem-

perature is exceeded. Thus a high-pressure cut-out can

be avoided in many cases since the load on the con-

denser is reduced by lowering the frequency.

"Electronic low-pressure switch"

The low-pressure switch function switches the com-

pressor off as soon as the pressure falls below the set

pressure value. In contrast to the evaporation temperat-

ure limiter (pump down), the compressor is immediately

switched off as soon as this limit value is reached and

is not shut down via the ramp. Moreover, a fault is

stored in the fault memory of the VARIPACK frequency

inverter. As soon as the evaporation temperature set-

point is exceeded, the compressor is restarted.

"Electronic high-pressure switch"

The high-pressure switch function switches the com-

pressor off as soon as the set pressure value is ex-

ceeded. The standard setting and the maximum ad-

justable value corresponds to the maximum operating

pressure of the compressor. The high-pressure switch

is reset as soon as the temperature falls below the set

value of the condensing temperature limiter.

Information

The electronic high-pressure switch function

does not replace the type-examinated tested

high-pressure switch according to EN 378!

Содержание VARIPACK FDU+12

Страница 12: ...CB 100 1 12 1 2 3 4 Abb 7 Steuremodul abmontieren...

Страница 46: ...CB 100 1 46 1 2 3 4 Fig 7 Dismounting the control module...

Страница 64: ...CB 100 1 64 Fig 17 Graphical representation of the general control functions of the extension module...

Страница 70: ...Notes...

Страница 71: ...Notes...