CB-100-1

55

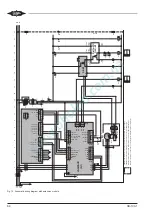

Schematic wiring diagram

Connect the VARIPACK frequency inverter in accord-

ance with the schematic wiring diagrams. Mount the

control switches S1 to S3 in the switch cabinet.

Individual connection of the compressor motor accord-

ing to the selected motor version and design. For de-

tails concerning the motor connection, see inside the

terminal box of the compressor.

The schematic wiring diagrams include an optional oil

monitoring. Without such a monitoring, the Delta-PII re-

spect. OLC-K1 and the components S3 and H2 can be

omitted. The auxiliary relay K11 and the pressure

switches F5 and F6 should in this case be installed in

path 15 at the connection 14 of the SE-B1.

In contrast to the safety levels obtained by VARIPACK

frequency inverters (PLe, SIL3), the integration in the

system shown in the schematic wiring diagrams corres-

ponds to a max. safety level of (PLd, SIL2). The actual

safety levels valid for the entire system can exclusively

be calculated by the system manufacturer! The obtain-

able safety level shown in the schematic wiring dia-

grams is usually satisfactory for refrigeration systems.

For comparison: a simple contactor circuit that is usu-

ally used, without using two contactors with mutual

monitoring connected in series, corresponds to a max.

reachable safety level of PLc/SIL2. The required safety

level must be defined by the system manufacturer on

the basis of a risk assessment. For further information,

see chapter Safe Torque Off (STO), page 60.

Abbr.

Component

B1

Control unit (cooling demand) or com-

mand for compressor start (release sig-

nal from the system controller) or con-

troller On/Off

F1

Main fuse

F2

Compressor fuse

F3

Control fuse

F12

Oil heater fuse

F17

Control transformer fuse

H1

Signal lamp "over temperature" (motor

and discharge gas)

H2

Signal lamp "Oil supply fault"

H6

Signal lamp "Ready-to-operate"

K10

Auxiliary relay "Compressor is running"

K11

Auxiliary relay "Compressor release"

M1

Compressor

N1

VARIPACK frequency inverter (FI)

Q1

Main switch

R1 .. 6

PTC sensor in the motor winding

Abbr.

Component

R7

Discharge gas temperature sensor (op-

tion)

R8

Oil heater (option)

S1

Control switch (on/off)

S2

Fault reset "over temperature" (motor

and discharge gas)

S3

Fault reset "Oil supply fault"

T1

Control transformer (for example 230 V)

Y2

Solenoid valve "Liquid line"

Tab. 4: Legend for the schematic wiring diagrams VARIPACK

SE-B1: Protection device.

Delta PII or OLC-K1: Oil monitoring (option).

Содержание VARIPACK FDU+12

Страница 12: ...CB 100 1 12 1 2 3 4 Abb 7 Steuremodul abmontieren...

Страница 46: ...CB 100 1 46 1 2 3 4 Fig 7 Dismounting the control module...

Страница 64: ...CB 100 1 64 Fig 17 Graphical representation of the general control functions of the extension module...

Страница 70: ...Notes...

Страница 71: ...Notes...