Section F. Adjustments

Belarus-510/512

Operating manual

73

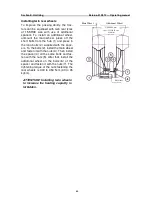

the handle 4 and the cock 1 of the lock

sensor, proceeding as follows:

a) fasten the free end of the cable 2 in

the clamp with the screw 3, at that

the cable end must protrude from the

clamp to 5 to 10 mm max.;

b) shift the handle 4 to the position I.

Stretch the cable until the cock starts

turning and lock the coupling with

the screws 3; lead the second clamp

up against the coupling and fasten it

with the screw.

To check correctness of the adjustment,

shift the handle to the fixed position II, at

that the mark on the cock 1 must align

with the mark “

вкл

.” (“on”) on the lock

sensor cover. The handle and the cock

must return to the position I from the po-

sitions II and III under action of the

spring.

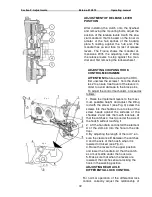

ADJUSTING FDA CARDAN DRIVE

In the cardan drive, adjust the safety

coupling in the intermediate support and

check the side play in the cardan bear-

ings.

Adjust the safety coupling to transfer of a

torque of 40 to 80 kgf•m (400 to 800 N•m).

Adjust the coupling by tightening the nut 2 of

the rear shaft shank of the intermediate sup-

port to ensure transfer of the required torque.

Periodically check the side play in the uni-

versal joint cross bearings. If any play is pre-

sent, disassemble the joint and check condi-

tion of the bearings and crosses, replace

worn parts. When assembling the gland

holders, press them in up to stop against the

bearing.

The driveshaft is balanced dynamically. Do

not disassemble the driveshaft without a

special need. When replacing parts such as

pipe with joint forks and flange during opera-

tion, balance the driveshaft assembly with

two joints again dynamically by welding

plates to the both ends of the pipe. Unbal-

ance must not exceed 55 g•cm. Do not crank

the driveshafts with tire levers, keys or other

devices to avoid damage to sealings and

failures of cross bearings.