Section G. Maintenance Belarus– 510/512 Operating manual

99

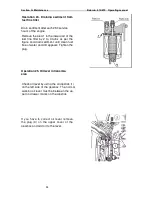

Operation 32. Replacing filtering ele-

ment of fuel fine filter

• Service life of a fuel fine filter de-

pends on purity of fuel applied.

• Replace the filter as per the figure

proceeding as follows:

• - drain fuel from the filter by un-

screwing the plug 4 in the lower part

of the housing

Do not let the fuel to spill over, drain it

only to a container.

• - unscrew the filter 1 from the adapt-

er 8 in the housing 2 and install a

new filter instead of it, which is sup-

plied assembled with the gasket 7

that must be first lubricated with mo-

tor oil;

• - after the gasket 7 touches the in-

stallation seat A on the housing 2,

screw in the filter by an additional ¾

turn. At that, screw in the filter only by

force of the hands;

• - open the fuel tank valve and fill the

system with fuel.

1 - filter

ФТО

20-1117010; 2 – housing; 3

— holder; 4 — plug (to drain sediment); 5

— return line pipe; 6 — plug (to bleed

air); 7 — gasket; 8 — adapter.

•

To bleed air from the system:

• To bleed air from the system, unscrew

the plug 6 on the bolt fastening the re-

turn line pipe by 2 to 3 turns. Purge

the system with the hand purge pump

3, screwing in the plug when fuel

without air bubbles emerges.

• Unscrew the plug 2 on the fuel pump

housing. Purge the system with the

hand purge pump until fuel without air

bubbles emerges, screwing in the

plug 2 at that.

•

Instead of the FT020-1117010 filter

other sealed fuel filters can be in-

stalled with basic specifications and

dimentions as follows:

• screening capacity 90% min.;

• conditional throughput capacity at a

pressure difference of 0.01 MPa of

150 l/h min.;

• diameter 95 to 105 mm;

• height 140 to 160 mm;

• connection thread M16×1.5;

• gasket outer diameter 70 to 75 mm.