Service Manual

Last Updated - 9/28/2016

495B SE (S)

36

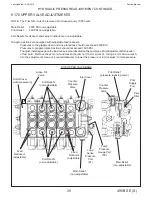

ADJUSTING WORKING PRESSURE (3600 PSI) AND STANDBY PRESSURE (425 PSI)

Standby pressure

Pump compensator

Torque Control

1. Install an electronic (digital) gauge on the system pressure test port (which is located on the main control

valve).

NOTE: When setting standby pressure, pressure will spike to approx. 3600 PSI before reading 425 PSI. This

will ruin a 1000 PSI gauge. Use an electronic (digital) gauge to check standby pressure.

2. With engine at low throttle, set standby pressure to 425 PSI (turn screw clockwise to increase,

counterclockwise to

decrease).

3. To adjust pressure, loosen jam nut on pressure control block located on pump with 1/2" wrench. Adjust

pressure by turning screw in or out with a 5/32" allen wrench. Retighten jam nut prior to taking pressure

reading.

4. Install a 5000 PSI gauge on the system pressure test port (located on the fire wall, or the PX port on the

upper

control valve).

5. With engine at low throttle, bottom out the main boom (up) or stick boom (in or out) and set the system

pressure on the compensator screw to 3600 PSI (turn screw clockwise to increase, counterclockwise to

decrease).

The torque control is factory set and generally will not require adjustment. Turning the screw in (clockwise) will

increase the load on the engine by holding the pumps on stroke at a higher pressure.

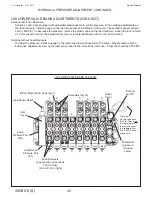

HYDRAULIC PRESSURE ADJUSTMENTS

PUMP ADJUSTMENTS (A11VLO-145)

Содержание 495B - SE

Страница 3: ...Introduction...

Страница 15: ...Maintenance...

Страница 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Страница 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Страница 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Страница 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Страница 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

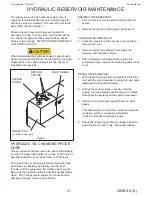

Страница 28: ...Hydraulic...

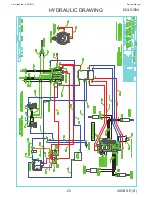

Страница 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Страница 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

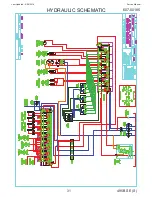

Страница 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

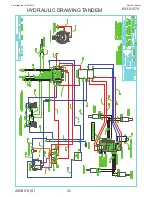

Страница 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

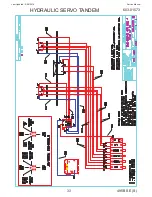

Страница 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

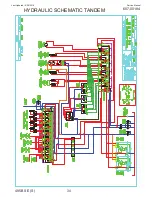

Страница 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Страница 56: ...Electrical...

Страница 57: ...Service Manual 495B SE S 57 Last Updated 9 28 2016 ELEC SCHEMATIC 460V 3PH 60HZ 100HP 903 00106...

Страница 58: ...Service Manual Last Updated 9 28 2016 495B SE S 58 ELEC SCHEMATIC 575V 3PH 60HZ 100HP 903 00149...

Страница 59: ...Service Manual 495B SE S 59 Last Updated 9 28 2016 ELEC SCHEMATIC 380V 3PH 50HZ 125HP 903 00225...

Страница 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 75: ...Service Manual 495B SE S 75 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED 1 2 3 4 5 6 2 7 8...

Страница 78: ...Maintenance...

Страница 88: ...Structural...

Страница 93: ...Trouble Shooting...