Service Manual

Last Updated - 9/28/2016

495B SE (S)

26

SPECIAL TORQUE SPECIFICATIONS

LUBRICATE WITH ANTI-SEIZE COMPOUND PART NO. 514-00700

Other torques, for the valves, pumps, and motors are found in the service literature for those components.

Swing Motor Mounting Bolts ....................................................................... 80 Ft. Lbs.(109 Nm)

Swing Motor Gearbox Mounting Bolts ........................................................ 80 Ft. Lbs.(109 Nm)

Turntable Bearing Bolts (upper) (Do not re-use old bolts/nuts) ................. 331 Ft. Lbs.(448 Nm)

Turntable Bearing Bolts (lower) (Do not re-use old bolts/nuts) .................. 331 Ft. Lbs.(448 Nm)

Loader Mounting Studs and Nuts ............................................................... 600 Ft. Lbs.(814 Nm)

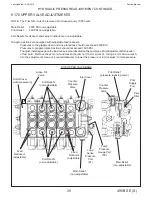

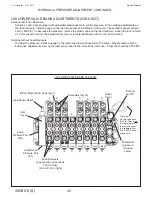

Valve Bank Studs/Nuts:

Tighten in a clockwise pattern so that all nuts are tightened equally without binding on the valve bank.

Final torque should be:

K170 valves ...............................................................................................44 Ft. Lbs.(60 Nm)

K220 valves ...............................................................................................59 Ft. Lbs.(80 Nm)

L90 valves ..................................................................................................33 Ft. Lbs.(45 Nm)

495ML MAGNUM PLUS TM

Loose or overtorqued bolts can cause death, severe

injury, or property damage. Maintain proper bolt torque.

Visually check bolts daily. Check torque every 100

hours.

In critical applications (such as Turntable Bearing Bolts

and any grade 8 or grade 9 bolts), once the old bolts

and nuts have been loosened, they must be replaced

rather than re-tightened and re-torqued. Original clamp-

ing force cannot be achieved using the old bolts and

nuts.

Содержание 495B - SE

Страница 3: ...Introduction...

Страница 15: ...Maintenance...

Страница 18: ...Service Manual Last Updated 9 28 2016 495B SE S 18 SERVICE SCHEDULE...

Страница 19: ...Service Manual 495B SE S 19 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Страница 20: ...Service Manual Last Updated 9 28 2016 495B SE S 20 SERVICE SCHEDULE CONTINUED...

Страница 21: ...Service Manual 495B SE S 21 Last Updated 9 28 2016 SERVICE SCHEDULE CONTINUED...

Страница 22: ...Service Manual Last Updated 9 28 2016 495B SE S 22 SERVICE SCHEDULE CONTINUED...

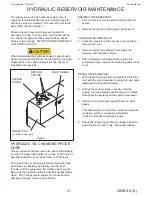

Страница 28: ...Hydraulic...

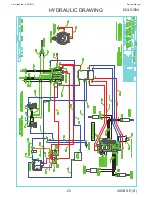

Страница 29: ...Service Manual 495B SE S 29 Last Updated 9 28 2016 HYDRAULIC DRAWING 603 01594...

Страница 30: ...Service Manual Last Updated 9 28 2016 495B SE S 30 HYDRAULIC SERVO DRAWING 603 01593...

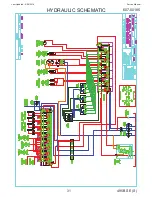

Страница 31: ...Service Manual 495B SE S 31 Last Updated 9 28 2016 HYDRAULIC SCHEMATIC 607 00185...

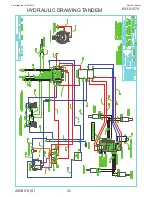

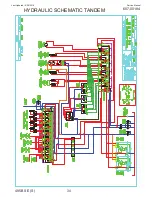

Страница 32: ...Service Manual Last Updated 9 28 2016 495B SE S 32 HYDRAULIC DRAWING TANDEM 603 01574...

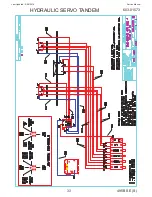

Страница 33: ...Service Manual 495B SE S 33 Last Updated 9 28 2016 HYDRAULIC SERVO TANDEM 603 01573...

Страница 34: ...Service Manual Last Updated 9 28 2016 495B SE S 34 HYDRAULIC SCHEMATIC TANDEM 607 00184...

Страница 56: ...Electrical...

Страница 57: ...Service Manual 495B SE S 57 Last Updated 9 28 2016 ELEC SCHEMATIC 460V 3PH 60HZ 100HP 903 00106...

Страница 58: ...Service Manual Last Updated 9 28 2016 495B SE S 58 ELEC SCHEMATIC 575V 3PH 60HZ 100HP 903 00149...

Страница 59: ...Service Manual 495B SE S 59 Last Updated 9 28 2016 ELEC SCHEMATIC 380V 3PH 50HZ 125HP 903 00225...

Страница 71: ...Service Manual 495B SE S 71 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 72: ...Service Manual Last Updated 9 28 2016 495B SE S 72 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 73: ...Service Manual 495B SE S 73 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 74: ...Service Manual Last Updated 9 28 2016 495B SE S 74 AIR CONDITIONER MAINTENANCE CONTINUED...

Страница 75: ...Service Manual 495B SE S 75 Last Updated 9 28 2016 AIR CONDITIONER MAINTENANCE CONTINUED 1 2 3 4 5 6 2 7 8...

Страница 78: ...Maintenance...

Страница 88: ...Structural...

Страница 93: ...Trouble Shooting...