153

6.2.21

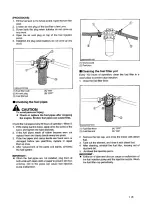

Track inspection and tensioning

Check track tension at the inspection frequency indicated in the general chart.

Pull the track slightly upwards in correspondence with the centre line; the

deformation must be of approximately 2 cm.

If the track sags and becomes too noisy as it moves, it must be tightened as

described below:

1)

Remove the guards (

1

)

2)

For proper track tension use a tensioning kit (

2

) - not included - and pump

grease into the tensioning valve

(3

) until it reaches the pressure indicated

below. Consult the grease chart on the next pages for the type of grease

required.

Max pressure for track tensioning

Bar

300

Содержание 1090 EVO

Страница 7: ...7...

Страница 10: ...10 Maximum transport height allowed manual levelling and the adjustment of the travel speed is allowed...

Страница 22: ...22...

Страница 23: ...23...

Страница 49: ...49 37 Combustion engine 38 Fuel tank 39 Bi levelling chassis 37 38...

Страница 78: ...78...

Страница 80: ...80...

Страница 122: ...122 In this configuration the oil level must be as shown in the figure below A 60mm...

Страница 144: ...144...

Страница 145: ...145...

Страница 146: ...146...

Страница 147: ...147...

Страница 148: ...148...

Страница 149: ...149...

Страница 150: ...150...

Страница 151: ...151...

Страница 152: ...152...

Страница 156: ...156 6 Using the nut supplied point A 7 Move the front wheel back by pressing on the track with your foot...

Страница 161: ...161 8 ATTACHMENTS 8 1 Declaration of conformity...

Страница 163: ...163 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

Страница 177: ...177 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...