Page 5-4

INPORTANT

1.

Carefully mount the chuck with it stabilized by using the lifting belt or

touching the chuck to the spindle.

2.

Tighten the chuck mounting bolts with specified torque(unequal tightening

will cause chuck run-out)

3.

To install the chuck accurately, mount it so that the chuck run-out and face

run-out are within 0.02mm(target 0.01mm or less).

4.

If chuck run-out accuracy is over 0.02mm, loosen the mounting bolts to shift

chuck position 120 and tighten the boles again with the same way.

5.4 MAINTENANCE AND INSPECTION

1.

Clean engagement part in the chuck body and jaw

2.

Lubricate in ball cap and the engagement part in the chuck body and jaw

1 or 2 times a day.

3.

If sward or foreign matter is caught inside chuck(scroll, gear part), remove

the chuck immediately and disassemble and clean it.

Содержание ATL 1820E

Страница 5: ...1 SAFETY INSTRUCTIONS ...

Страница 22: ...Page 1 17 ...

Страница 24: ...2 MACHINE SPECIFICATIONS ...

Страница 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Страница 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Страница 31: ...3 INSTALLATION ...

Страница 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Страница 43: ...4 MAINTENANCE ...

Страница 55: ...5 CHUCK ...

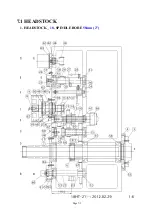

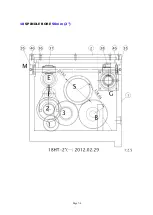

Страница 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Страница 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Страница 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Страница 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

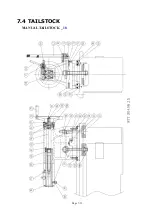

Страница 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...