Page 4-4

Follow the following steps to re-align tailstock to the spindle.

1)

Insert a gauge bar between the spindle and tailstock, attach the base of a

test indicator to the saddle, and apply the stylus of the indicator to the

surface of the bar, of its maximal difference for later adjustment.

2)

Release the fixing screw 1 and adjust the adjusting screw 2 to fine the

alignment.

4.2.4

4.2.5

4.2.5 Adjusting belt tension of spindle

The main spindle torque which depends on the motor power transmitted

through the belt, the operator must check the V belt’s tension frequently by

adjusting screw if it becomes loosen.

4.2.6 Adjusting belt tension of x-axis

The new belt tension of X-axis should be 2.9mm elastic length when pressed by

1kg force. After a period of time, if the belt turned looser, adjust the belt to be

2.9mm by 1kg.

4.3 Electric equipment

4.3.1 Motor

Содержание ATL 1820E

Страница 5: ...1 SAFETY INSTRUCTIONS ...

Страница 22: ...Page 1 17 ...

Страница 24: ...2 MACHINE SPECIFICATIONS ...

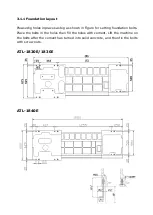

Страница 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Страница 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Страница 31: ...3 INSTALLATION ...

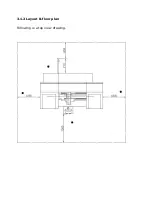

Страница 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Страница 43: ...4 MAINTENANCE ...

Страница 55: ...5 CHUCK ...

Страница 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Страница 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Страница 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Страница 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Страница 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...