* Note whether motor is running or not.

1)

Fill clean lubricant into the oil tank up to the “MAX” marking of the oil level

indicator.

2)

The oil tank preserves clean lubricant.

3)

In case impurity remains in the oil tank so as to fail the oil feeding, please

clean the oil absorbing net immediately.

4)

Firstly, push oil feeding button to fill up the empty pipes for normal

application.

5)

The adjustment of discharge (Fig, shown) is to release the fixing bolt and

adjust it at desired figure displayed on the scale plate, so the figure is to

show the discharge C cc/cy.

6)

Oil surface below the ‘’MIN’’ limit, it is necessary to refill oil.

CESH-TYPE

FEATURES

1) This product is applied to every part of a machine which is needing to be

lubricated centralize the mounting together with proper spare parts of piping

to apply lubricants automatically by means of this machine. The oil feeding

machine provided oil feeding times with precision to improve lubricating

efficiency and lower cost.

2) Starting this machine is on “OFF”, it can avoided your re-actuated this

machine too much feeding oil.

3) For the adjustment of the dispose volume, set the “ON”and“OFF” at the

respective position for the selected discharge amount, and the operation is

simple.

4) If continued or more lubricating is required please actuate the coercive

pumping switch.

5) According to the division of timer set “ON” and “OFF times (in 3% error).

6) The pressure switch and buzzer are additional equipment at your option.

SPECIFICATION

TIMER

ON (ON TIME)

0-60 min.

*

ALM

*

FLOATING SWITCH

A (MAX. 1A )

*

BUZZER

AC 110V/220V

MOTOR

VOLTAGE/HZ

110V/50/60HZ 220V/50/60HZ

CURRENT

0.3A

0.1A

OUTPUT 5 EXTREMILY

12W x 4P

Содержание ATL 1820E

Страница 5: ...1 SAFETY INSTRUCTIONS ...

Страница 22: ...Page 1 17 ...

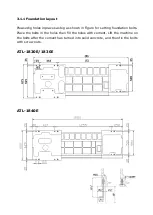

Страница 24: ...2 MACHINE SPECIFICATIONS ...

Страница 25: ...Page 2 1 2 MACHINE SPECIFICATIONS 2 1 Dimensional drawing ...

Страница 27: ...Page 2 3 2 1 2 Chip Conveyor ...

Страница 31: ...3 INSTALLATION ...

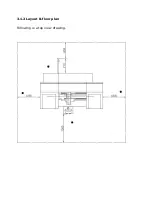

Страница 34: ...3 1 2 Layout floor plan Following is a top view drawing ...

Страница 43: ...4 MAINTENANCE ...

Страница 55: ...5 CHUCK ...

Страница 64: ...Page 7 3 7 1 HEADSTOCK 1 HEADSTOCK _ 18 SPINDLE BORE 58mm 2 ...

Страница 65: ...Page 7 4 18 SPINDLE BORE 58mm 2 ...

Страница 69: ...Page 7 8 7 2 BED Z AXIS TRANSMISSION ...

Страница 71: ...Page 7 10 7 3 CARRIAGE CROSS SLIDE ...

Страница 74: ...Page 7 13 7 4 TAILSTOCK MANUAL TAILSTOCK _ 18 ...